Automated Cell Culture Platform

Automated parallelized cell culture platform for long-term cell perfusion

Highly controlled environment

Highly controlled extracellular environment with stable flow

Up to 4 independent cell cultures

Save time and improve reproducibility

Up to 3-week cell cultures

Less manual work and more accuracy

Compatible with CO2 incubator

Adapted to standard CO2 incubators and biosafety hoods

Need a microfluidic SME partner for your Horizon Europe project?

Automated cell culture platform

Highly controlled microenvironment

We have put together the best of our flow control technology to provide your dynamic cell culture with stable flow at a wide range of flow rates. Our cell culture platform is the perfect companion for your dynamic cell culture research, whether you culture cells for short experiments or days on end.

Up to 4 parallel and independent cell cultures

To save time and increase the reproducibility of your results, our cell culture platform allows you to perform up to 4 cell cultures independently and simultaneously.

Enrich your media with metabolites with our compact recirculation bridge

Plug and play assembly

Enough with the complicated assemblies! With our microfluidic cell culture platform, you can connect and control up to 8 reservoirs with a click.

Compatible with standard CO2 incubators and biosafety food

Designed to fit seamlessly with your regular labwork routine, our cell culture platform fits in standard CO2 incubators and biosafety hoods. The cell culturing platform is portable and can be assembled under the biosafety hood.

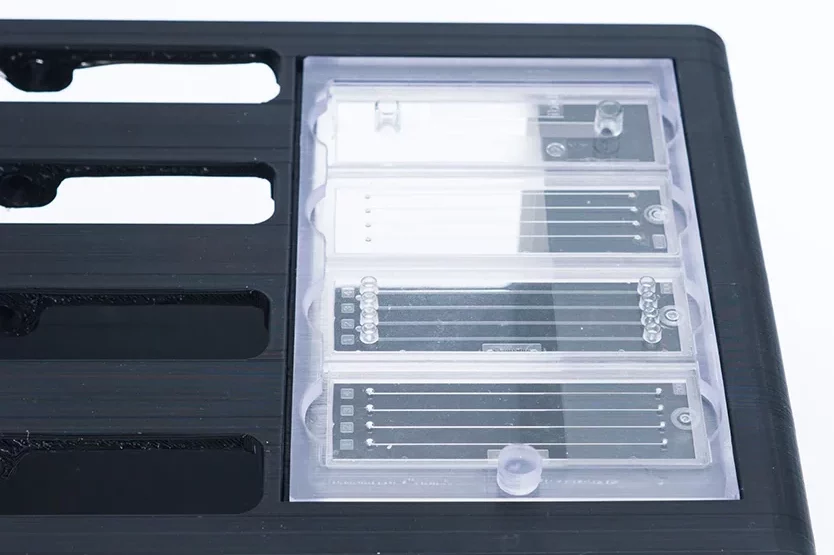

Easily adapted to microscope stages

Our Microfluidic cell culture platform is equipped with two culturing chamber options. You can choose between a slide holder that fits into standard microscope stages or a bioreactor for 3D or low-shear cell culture. In both cases, you can conveniently transfer your samples from the system to the microscope for imaging.

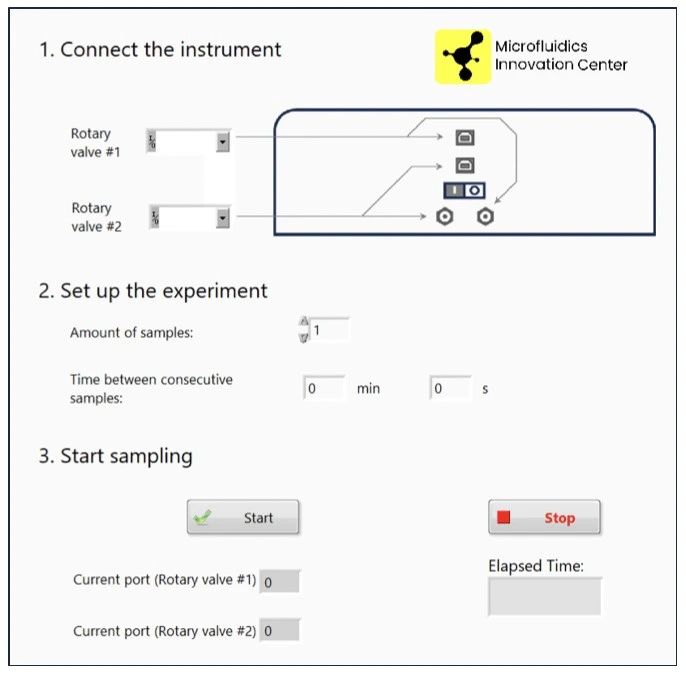

Automation and control with a single software interface

User-friendly and intuitive software to get started in a few clicks and further automate the most complex and long-lasting experiments. If you need more flexibility, SDK libraries to control the system with your code and to involve third parties instruments are also available.

Microfluidic cell culture applications

Traditional cell culture, that is, culturing cells in static conditions in flasks, is responsible for many advances in modern cell biology, such as developing the polio vaccine and discovering the connection between cancer and viruses [1]. However, this reductionist approach lacks important parameters for cell growth, such as shear stress and mechanical stimulus [2].

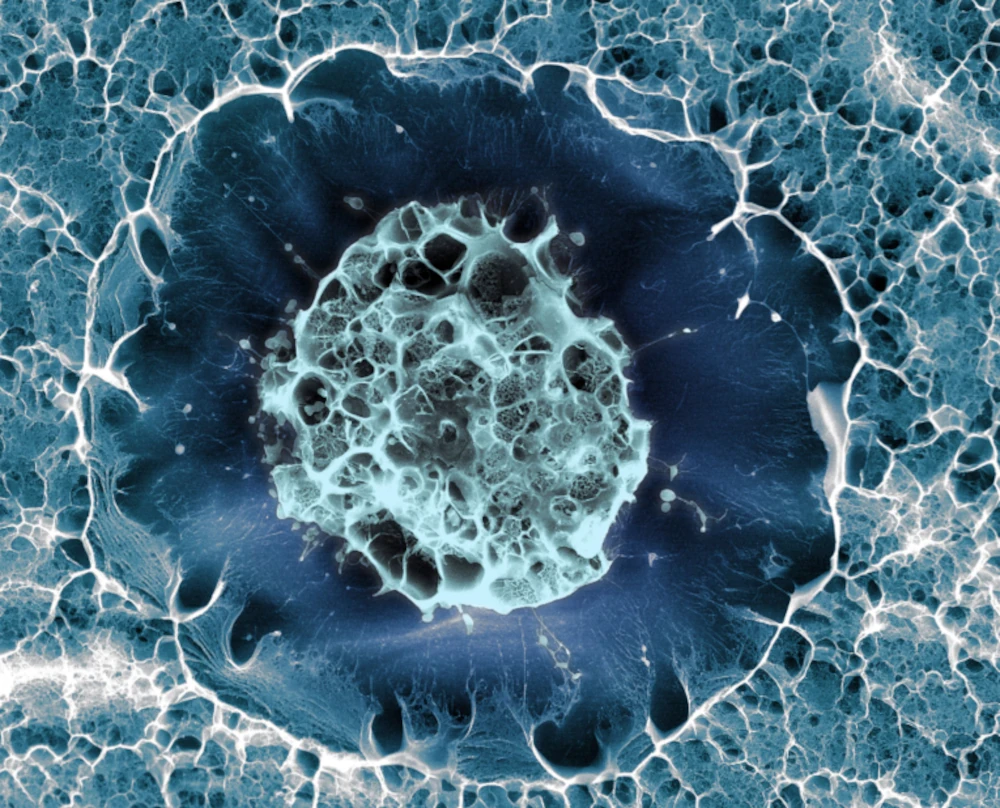

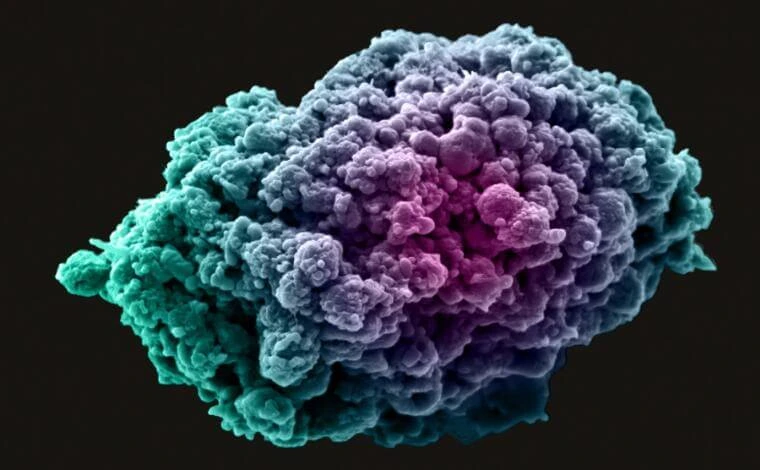

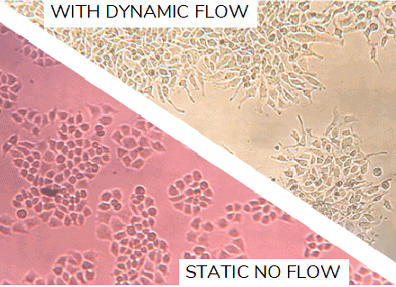

Microfluidic cell culture has gained relevance for enabling a more physiologically relevant microenvironment for cell growth, promoting more -like phenotypes, as seen in the image below. Moreover, it allows better usage of resources, as it can handle small volumes of media and automate manual tasks, freeing researchers from the labor-intensive requirements of traditional cell culture. Cells can be cultured in microfluidic chips, microfluidic perfusion chambers, or bioreactors, depending on the intended application [3].

Some applications of our microfluidic cell culture system include:

Stem cell culture

Automated and fail-safe long-term microfluidic cell culture system.

✓ Highly controlled microenvironment

✓ Fail-safe mechanism

✓ Automated sequences

Stem cell culture

Microfluidic spheroid cell culture

Plug-and-play instrument pack for automated scaffold-free 3d cell culture technique.

✓ Multiple Parallel culture of Spheroids

✓ Automated Spheroid Perfusion

✓ More Physiologically Relevant Model

Microfluidic spheroid cell culture

Blood-brain barrier on chip

Plug-and-play instrument pack for long term BBB on a chip study

✓ Relevant microenvironment

✓ Automatized organ-on-chip perfusion

✓ Plug-and-play microfluidic platform

Blood-brain barrier on chip

Live cell imaging

Keep ideal temperature and see your cells’ development in real time

✓ Accurate temperature control

✓ Up to 3 simultaneous devices

✓ For static or flow conditions

Live cell imaging

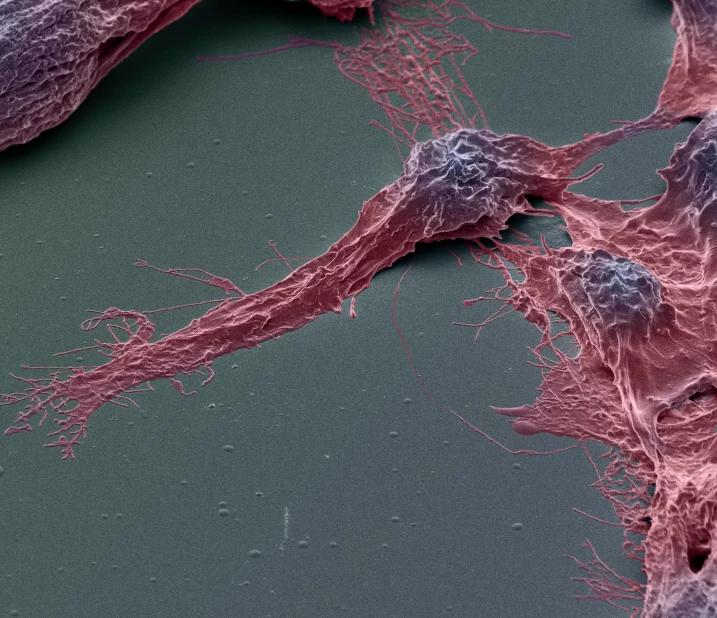

Sheer stress

Cell culture system for shear-sensitive cell lines

✓ Safe Neuron Culture Under Flow

✓ Highly Controlled Microenvironment

✓ Up to 3-week Long Cell Cultures

Sheer stress

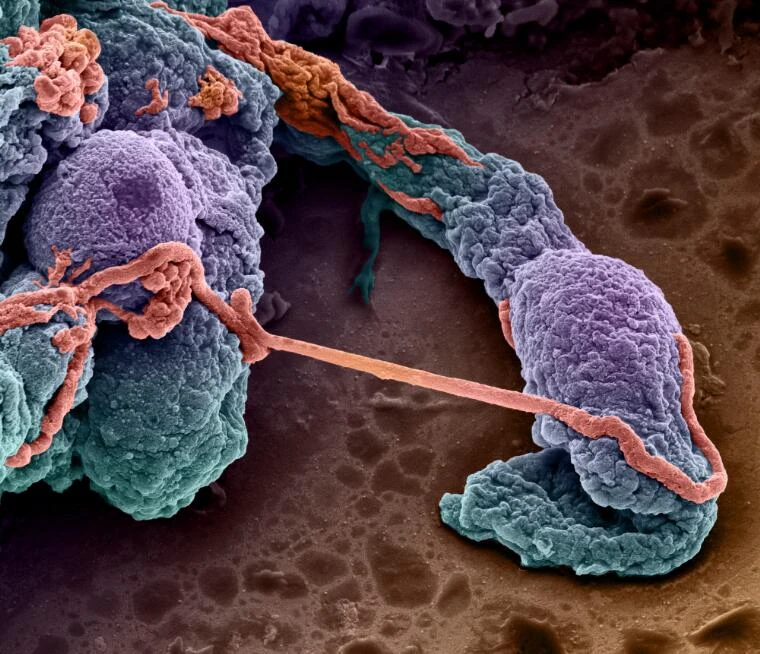

Cancer invasion and metastasis

Follow long-term cancer cell migration in real time on top of the microscope

✓ Keep Ideal Temperature Conditions

✓ Follow Cancer Cell Migration in Real Time

✓ Adapted to Cultures Under Flow

Cancer invasion and metastasis

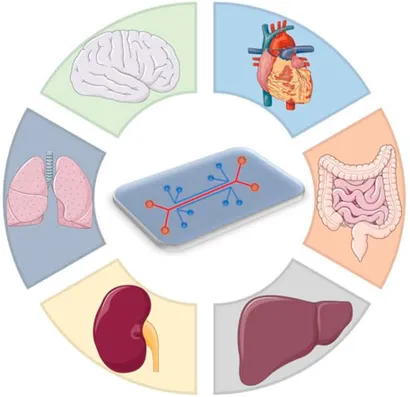

Organ-on-a-chip

Organ-on-a-chip technology emerged in the early 21st century as a revolutionary approach to simulate human organ functions in vitro.

Organ-on-a-chip

Blood-vessel-on-chip pack

Reproduce physiological flow conditions for vasculature assays

✓ Reproduce Physiological Shear Stress

✓ Unindirectional Flow

✓ Use the Device of Your Preference

Blood vessel formation & occlusion (Atherosclerosis)

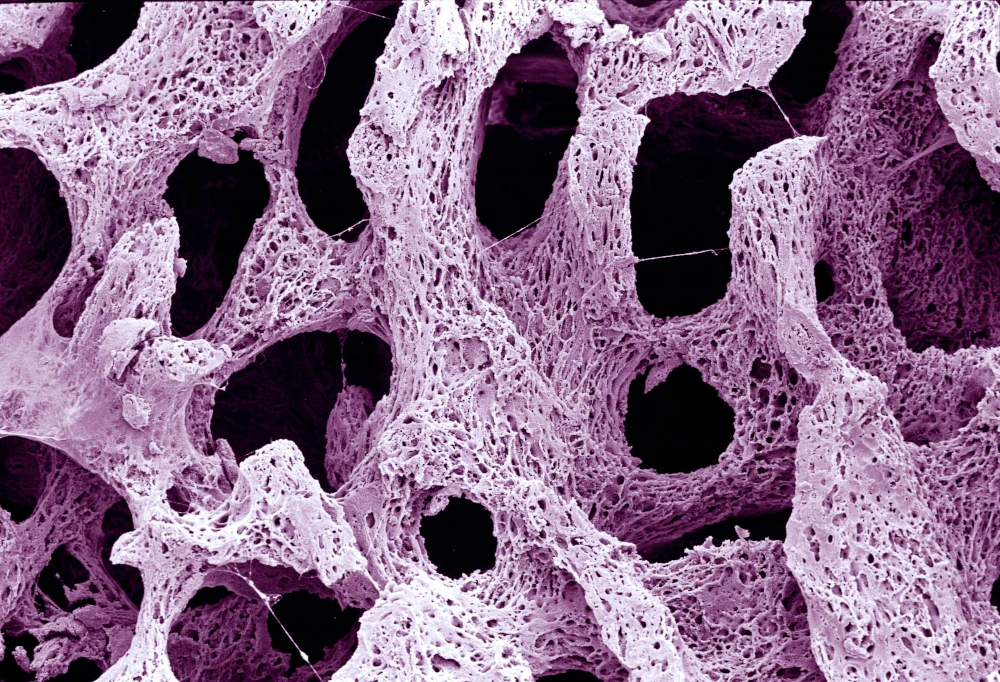

Bone-on-a-chip pack

Easily mimic the complex bone physiology and extracellular environment

✓ Control Complex Microenvironments

✓ Up to 3-week Long Cell Cultures

✓ Fail-Safe Mechanism

✓ Plug-and-Play Platform

Bone homeostasis and disease (Osteoporosis)

Drug screening

Immune response

Cell rolling-adhesion assay

Models of physiology and disease

And many more!

References

1. Lyapun, I. N., Andryukov, B. G. & Bynina, M. P. HeLa Cell Culture: Immortal Heritage of Henrietta Lacks. Mol. Genet. Microbiol. Virol. 34, 195–200 (2019).

2. Coluccio, M. L. et al. Microfluidic platforms for cell cultures and investigations. Microelectron. Eng. 208, 14–28 (2019).

3. Mehling, M. & Tay, S. Microfluidic cell culture. Curr. Opin. Biotechnol. 25, 95–102 (2014).

Cell culture technical specifications

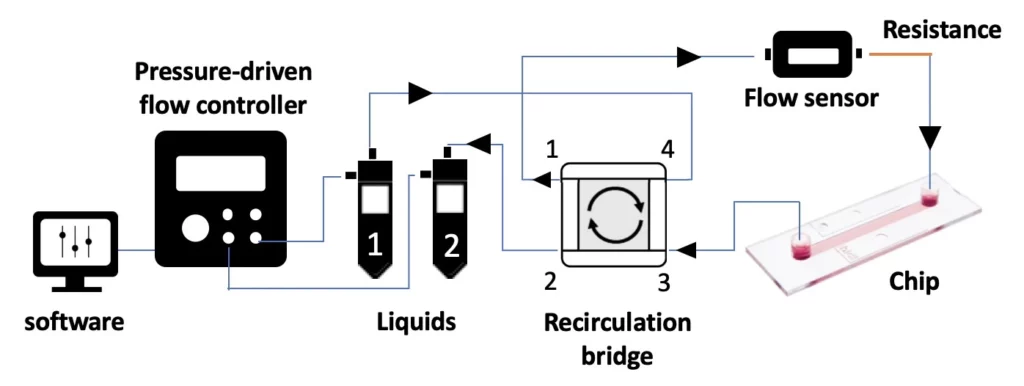

The cell culture system comprises a perfusion platform and a pressure splitter. The fluid flow is controlled by a flow controller.

The table summarizes the main specifications of the cell culture system.

| Components | Technical Specifications |

|---|---|

| OB1 MK4 (Elveflow) | 4 Channels (0 to 2000 mbar) |

| Microfluidic Flow sensor | Range from 0 to 5 mL/min |

| Recirculation loop | 4 check valves, polycarbonate, male Luer; compatible with 1/4″-28 standard microfluidic fittings |

| Pressure splitter (Elveflow) | Valve controller with integrated solenoid valves for compressed air |

| Cell culturing chamber | Microfluidic chips (2.55 x 7.55 cm) or Livebox 1 bioreactor (1,5 mL internal volume, IVT) |

The cell culture system is compatible with standard incubator conditions (37 oC, 5 % CO2, and 95 % humidity). Electronic components (except flow sensors) should be kept outside the incubator.

Customize your pack

Our instruments can be added to different setups depending on your specific needs. In this light, our microfluidic specialists will advise you on the best instruments and accessories depending on your needs and will accompany you during the system’s setup.

Frequently asked questions

What can be placed inside the incubator?

The cell culture platform and the embedded flow sensors can be placed inside the CO2 incubator. The OB1 and the pressure splitter should be kept outside.

What type of cells can be cultured with the platform?

The platform can be used to culture any cell type, as the culture media can be adjusted according to the cells’ needs, and the cell culturing chamber can be replaced by the required design.

Can the platform be sterilized/autoclaved?

The components of the cell culture platform can be sterilized. Our user guide provides detailed information on how to do it.

Is the platform compatible with microscopes/live cell imaging?

Yes, the system handles four microfluidic chips consecutively into a holder that fits a standard microscope stage. In the bioreactor case, LiveBox 1 bioreactors from IVT are compatible with live cell imaging.