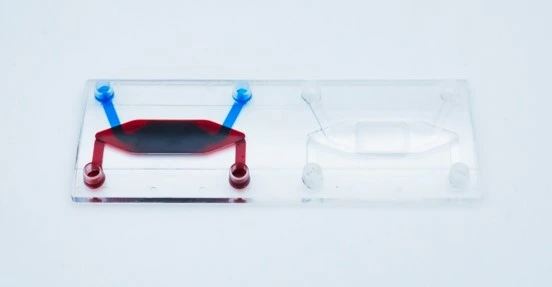

Thermoplastic Molding Microfluidics Setup

Move from PDMS to thermoplastic microfluidic chips

With only a few changes in your current microfabrication process

Compatible with different types of thermoplastic molding

COC, PMMA, PS, choose what best fits your needs

Fast process

Fabricate thermoplastic chips in only 1 hour

Need a microfluidic SME partner for your Horizon Europe project?

Thermoplastic molding microfluidics setup

Why switch to thermoplastic molding?

PDMS has been the working horse of microfluidics since its beginning. But as the technology matures, its limitations start to outweigh its perceived benefits, such as its easy and quick microfabrication process.

Researchers started looking for replacement materials, such as thermoplastics, because of limited chemical compatibility, high gas permeability, and low throughput.

However, thermoplastic molding for microfluidic chip fabrication can sound daunting, as it evokes extensive industrial facilities and complex machinery.

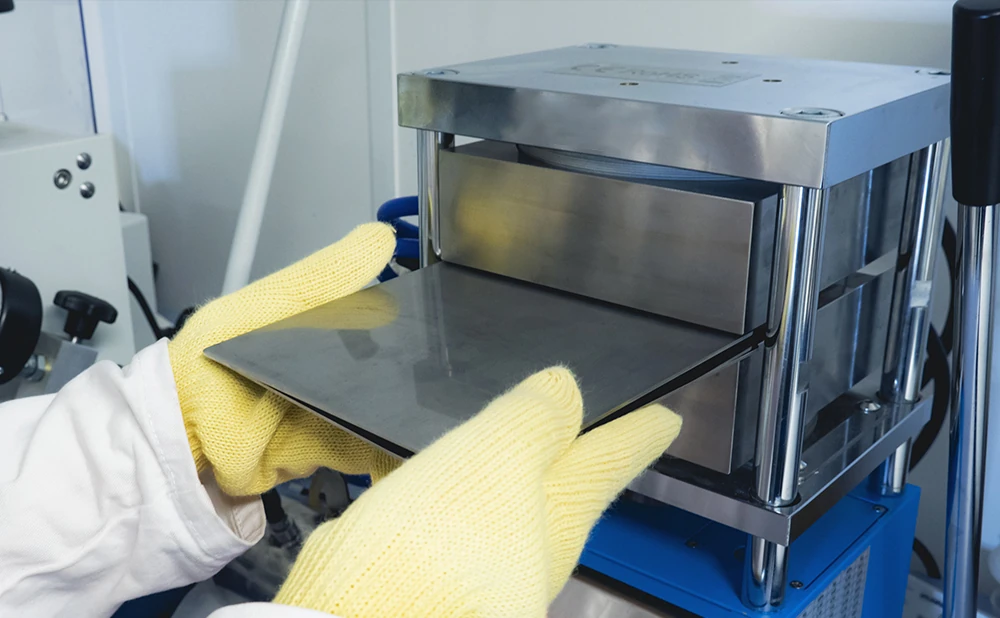

With that in mind, we challenged our capable team of engineers and researchers to come up with a way to adapt the current PDMS microfabrication process and turn it into a thermoplastic molding setup for microfluidic chip fabrication. And they were up to the challenge!

Let’s have a look at what they came up with:

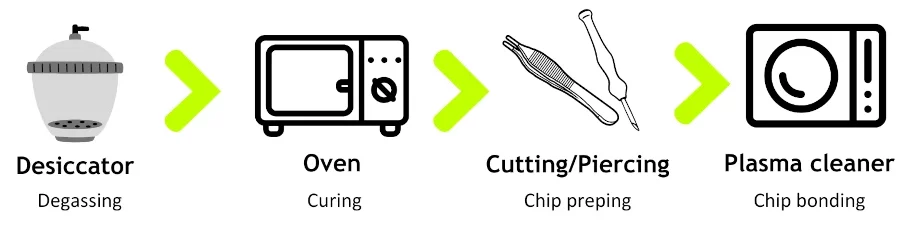

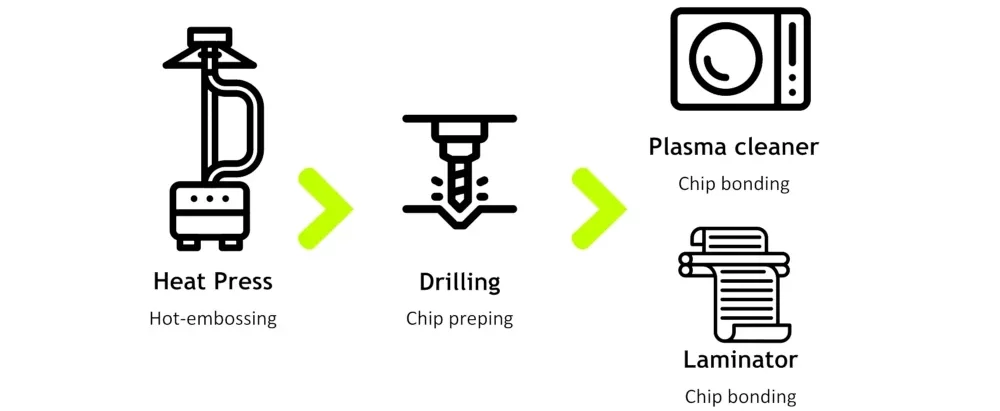

The PDMS microfabrication process starts with mixing PDMS with a curing agent and degassing inside a desiccator. Then, the elastomer is poured over the mold and cured in a conventional oven. Once ready, the chips are demolded and cut, and inlets are pierced with biopsy punchers. Lastly, the PDMS is bound to a glass slide after treatment in a plasma cleaner.

So, you only have to add our recommended heat press and laminator to your workflow and follow our instructions to be able to turn our PDMS microfabrication into a thermoplastic molding setup.

Your PDMS microfabrication process is different, and you don’t have all the listed equipment? Don’t worry; we’ve got you covered! We can provide you with all the necessary pieces and consumables; just drop us a line!

We recently published a review about the diverse materials and innovative fabrication and molding techniques used in microfluidic chip design.

Compatibility and applications

The thermoplastic molding setup can be used with:

PMMA device station

From mold development to high-resolution PMMA chip fabrication

✓ Fast process

✓ Multiple applications

✓ Simple and innovative setup

PMMA

COC polymer molding microfluidics setup

From PDMS to low-impurity high-performance COC polymer

✓ Fast process

✓ No need for a clean room

✓ Adaptable to your needs

COC

PS

Virtually any other thermoplastic

Applications are usually material-dependent, but in general terms, microfluidics chips produced with thermoplastic molding can be employed in:

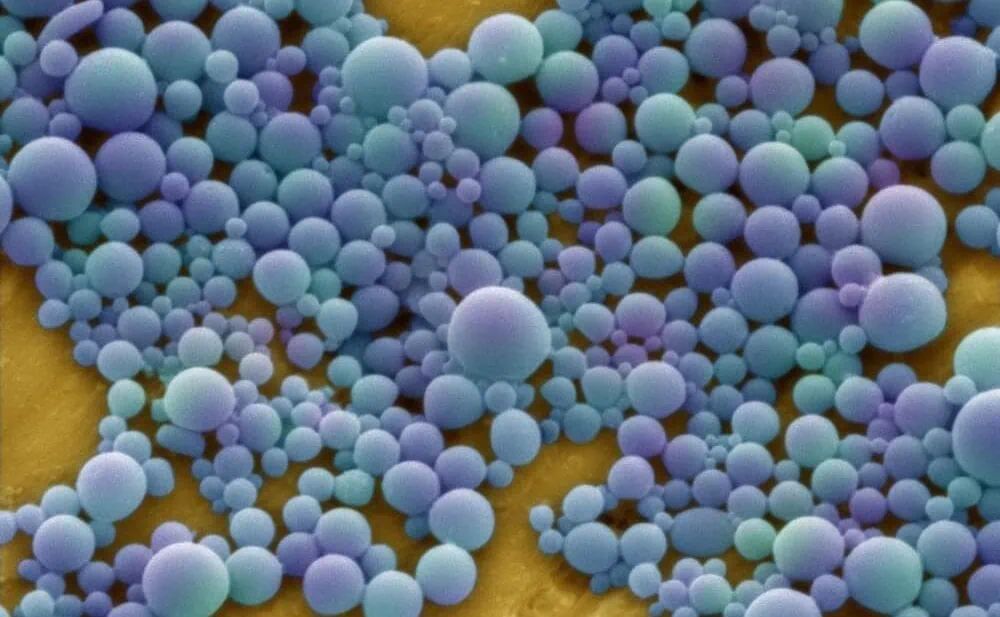

Microfluidics nanomaterial synthesis pack

Microfluidics for production of nanomaterials using sheath flow focusing

✓ Efficient synthesis. ofnanomaterials

✓ Easy microfluidic system implementation

✓ Biomedical applications

Lab-on-a-chip applications (e.g. nanomaterial synthesis)

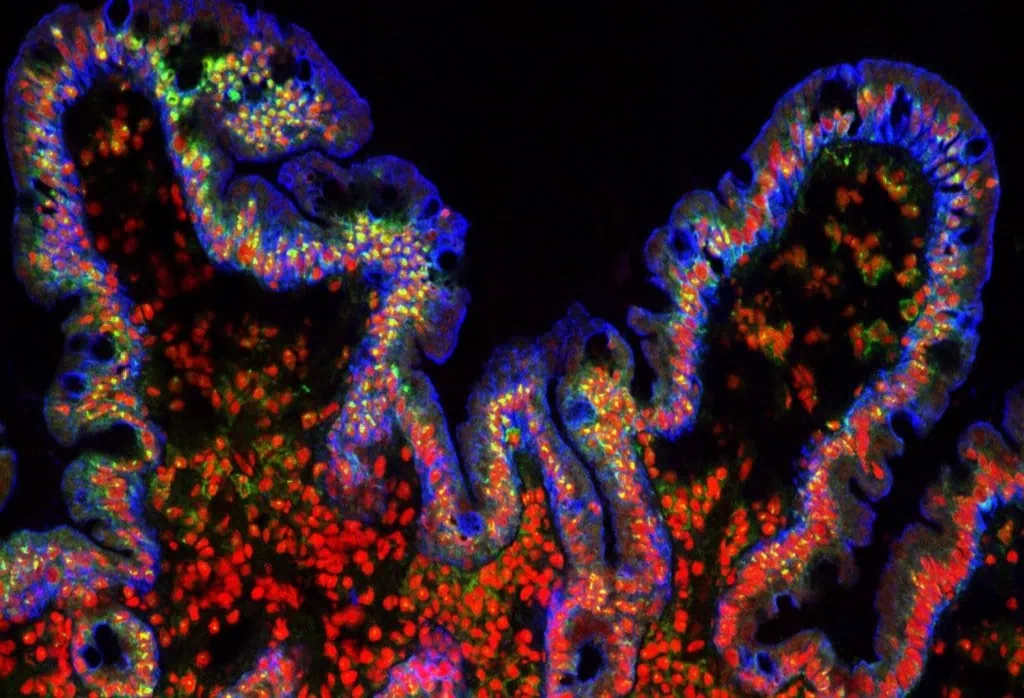

Gut-on-a-chip pack

Intestinal cells coculture under flow, mimicking the gut physiology

✓ All microfluidic pieces included, quick and easy assembly

✓ Dynamic culture conditions

✓ Advanced in viro/ex vivo

Gut-on-chip

Applications requiring specific-chip design and chemical inertia

Technical specifications

The thermoplastic molding microfluidic setup comprises:

Heat press with double heating plate

| Components | Technical specifications |

|---|---|

| Dimension | 420*550*680mm |

| Max temperature | 300℃ |

| Pressure range | 0-25 tons |

Laminator

| Components | Technical specifications |

|---|---|

| Dimension | 270*545*130 mm (L x w x h) |

| Max laminated width | 335 mm |

| Max laminated tickness | 35mm |

| Max temperature | 140 °C |

Options: Drilling machine

Consumables: Thermoplastic sheets of choice.

Frequently asked questions

Does the process also involve mold fabrication?

Currently, the thermoplastic molding microfluidic setup focuses on the chip fabrication and bonding from a pre-existing mold. However, we do have expertise to advise you in how to make your own molds.

What is the resolution of the thermoplastic microfluidic devices?

It depends on the chosen material, but for the PMMA devices done with this thermoplastic molding setup, for example, resolutions as low as 15 µm (channel width) for an aspect ratio of 2:1 can be achieved.

What maximum pressure can the devices withstand?

Based on internal testing, up to 3.5 bar.

What material can I use to close the chip?

The chip can be closed with a thermoplastic slide, a microscope glass slide or a microscopy-compatible polymer slide.

Is this process compatible with microscopy/reversed microscopy?

It depends on the properties of your thermoplastic of choice. PMMA, for example, is optically transparent and well-adapted to microscopy.