Patented technology

Microfluidic Flow Rate Sensor

Low flow rate microfluidic flow sensor with automatic clogging detection

Low flow rates

Accurate to below 1 µl/min

Detect clogging inside the sensor

Be alerted of issues

No drift

Trustworthy readings throughout

Need a microfluidic SME partner for your Horizon Europe project?

Microfluidic flow rate sensor highlights

Low flow rates

As the microfluidics field evolves, it stretches the capabilities of current instruments. The demand for low flow rates is an example. Current flow sensors cannot read below 1 µl/min accurately. Galileo was designed to bridge this technological gap, giving you accurate reading below 1µl/min.

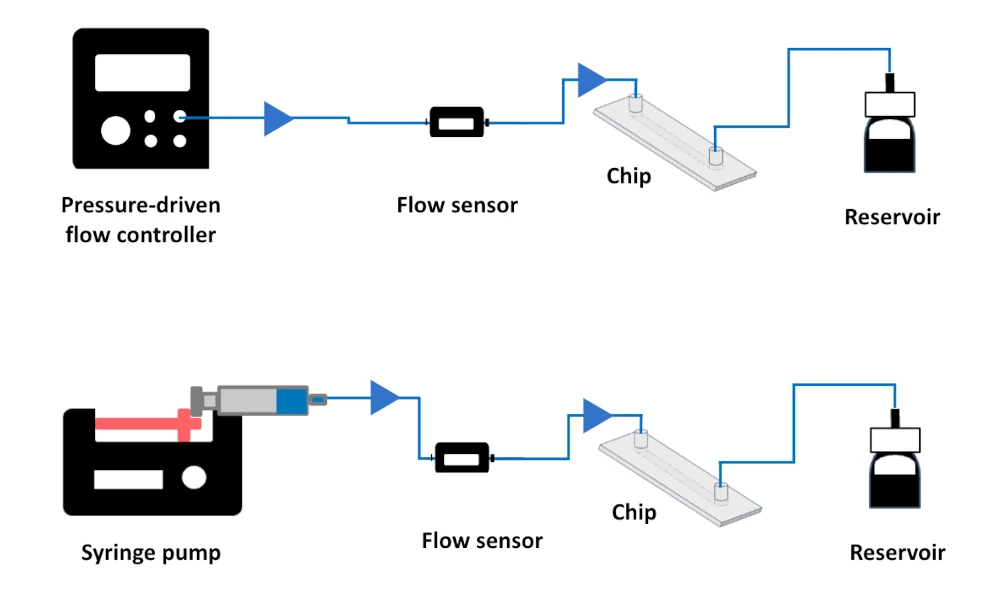

It was also designed to work with all types of pumps, such as pressure-driven flow controllers and syringe pumps, as can be seen in the schematics below.

Clogging detection

Microfluidics systems are complex because they depend on several parts put together: pumps, tubings, connectors, chips, sensors, valves, you name it. And when something goes wrong, a lot of time is lost trying to troubleshoot the whole system. To make life easier, our microfluidic flow sensor, Galileo, can alert you if the problem is coming from its internal fluidic path.

Drift detection

Through empirical observation, our team realised that flow sensors drift during long experiments due, for instance, to modification of the inner flow path of the sensor, i.e. biofouling by the accumulation of particles on the walls of the sensor.

So we developed a flow sensor that can detect if modifications are occurring within its channel walls. When drift occurs, it gives out a visual alert, so you can have 100% confident in your readings and take measures to correct any drift by easily replacing the cartridge.

The Microfluidics Innovation Center developed Galileo, a highly-performant microfluidic flow sensor with proven high accuracy, precision, and reliability.

The technology provides a robust and versatile solution for microfluidic applications thanks to its many features:

- <5% flow rate accuracy for any given range

- Configurable sensing ranges from 0.5 to 10,000 µL/min

- Fully replaceable cartridge format for range configuration and flow path replacement

- Automatic detection of internal clogging and measurement drift (e.g., biofouling)

- Bi-directional flow rate measurement (positive & negative)

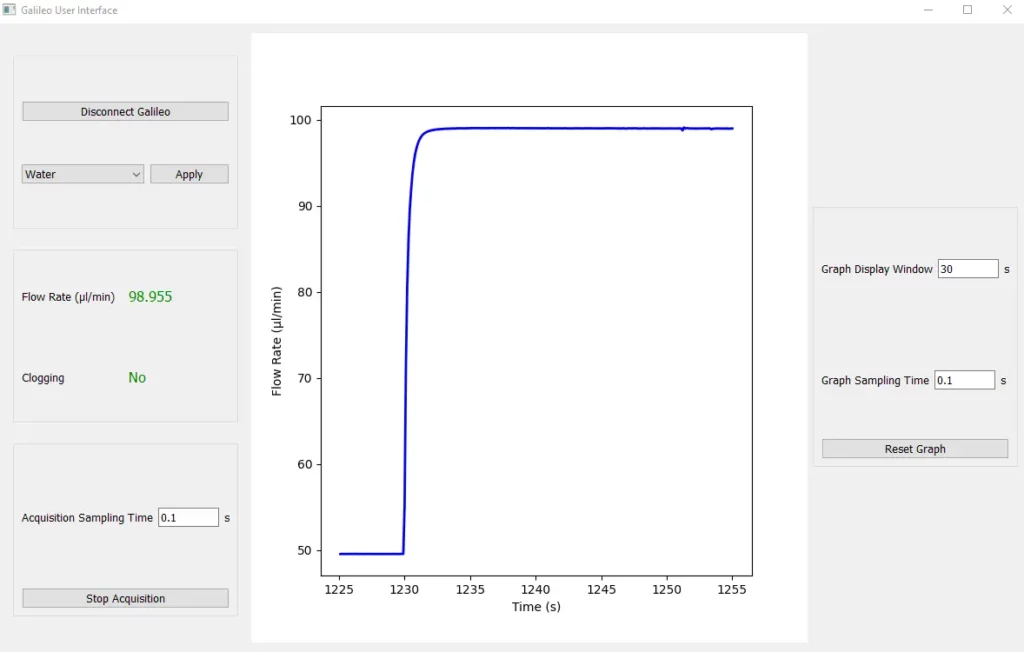

- Galileo user interface and LCD screen for direct flow rate monitoring

The Galileo Operation video offers clear step-by-step instructions on easily connecting the Galileo flow sensor and navigating the software interface. The video also includes a live demonstration of the sensor in action and a detailed explanation of the indicator lights.

Technical specifications

The technical specification sheet can be downloaded using the button below.

User guide

Please refer to the user guide for detailed instructions using the button below.

The Galileo Operation video gives some visual instructions on connecting the Galileo flow sensor and navigating the software interface.

Download the Galileo user interface

- Detection of the Galileo flow sensor

- Reading and plotting flow rate in real time

- Display of clogging detection flag

- Record flow rate and clogging detection with an acquisition rate of up to 100 Hz

Frequently asked questions

Can the cartridges be reused?

Yes, depending on your application. The flow sensor cartridges can be reused if there’s no alert of clogging, or if you face no problems of cross-contamination in your experiments.

With which types of pumps can the sensor be used?

Our microfluidic flow sensor can be used with all types of pumps, as it has an independent software that doesn’t depend on the flow generating system.

Can I have customized features?

We would love to hear what you have in mind. Drop us a line at innovation[at]microfluidic.fr or just click on the “get a quote” green button on top.