PMMA Device Station

From mold development to high-resolution PMMA chip fabrication

Fast process

A quick way to produce PMMA chips in less than a day

Multiple applications

Everything you need to fabricate a versatile and biocompatible microfluidic device

Simple and innovative setup

Rapid and customized installation

Need a microfluidic SME partner for your Horizon Europe project?

PMMA device station

Advantages

- Fast fabrication process to develop your chip in 5 hours or less.

- Fabricate your high-resolution devices without initial knowledge of microfabrication.

- Highly reproducible processes from reusable molds to PMMA chip fabrication.

- Get advantage of our expertise in photolithography and the hot embossing process.

- Inexpensive and innovative process suitable for different applications.

PMMA devices present properties that convey multiple advantages such as:

| Characteristics | PMMA | PDMS |

|---|---|---|

| Transparency | Transparent and optically clear | Transparent and optically clear |

| Fabrication | Machining, laser cutting | Soft lithography |

| Bonding | Solvent bonding, thermal bonding, or adhesive bonding | Oxygen plasma treatment or adhesive bonding |

| Elasticity | Rigid | Flexible and elastomeric |

| UV radiation resistivity | Moderate to high | Low |

| Surface properties | Hydrophobic, requires surface modification for hydrophilicity | Hydrophobic, naturally hydrophilic, can be surface modified |

| Gas permeability | Low | High |

| Chemical compatibility | Chemically resistant to many solvents and reagents | Limited chemical compatibility, can swell or leach components |

| Biocompatibility | Biocompatible with specific cell types and assays | Biocompatible with a wide range of biological samples |

| Connection options | External connectors (stainless, steel, plastic) | Tubing or syringe needles |

| Connector compatibility & ease of connection | Compatible with a variety of connector types: Requires proper alignment and connection of external connectors | Compatible with tubing or syringe needles: Tubing or needles can be easily inserted into the PDMS channels |

This pack guarantees a total and autonomous PMMA device manufacturing for microfluidics, Bio-MEMS, or other applications.

We recently published a review about the diverse materials and innovative fabrication and molding techniques used in microfluidic chip design.

PMMA device station setup

The PMMA device station includes the following:

Master mold fabrication (same as PDMS):

Laminator

UV lamp

Heat plate

PMMA replication:

Ultrasonic bath

Heat press

Oven

Pressurized air installation

Plasma cleaner

Materials:

We include all resources (PMMA film, dry photoresist film) and provide all product references needed to refill your stock in the future.

Accessories:

All lab accessories (glass slides, iron slides, slide holders, Petri dishes, tweezers, solvent bottles, thermal gloves, etc.) can be included. We also provide all product references needed to refill your stock in the future. The mask used depends on the application. Therefore, a mask design can be discussed.

Chemicals:

All chemicals (Isopropanol, acetone, developer, etc) can be included. We also provide all product references needed to refill your stock in the future.

We can also provide:

Ultrasonic bath

Drilling machine

Classical designs of photomasks

PMMA device applications

Thanks to its properties (transparency, recyclability, high biocompatibility), the PMMA device can be used for multiple applications, such as:

- Biomedical research and diagnostics: Thanks to their transparency, which facilitates imaging, PMMA devices can be used for cell culturing, drug screening, DNA analysis, protein assays, and point-of-care diagnostics.

- Droplet-based microfluidics: PMMA devices can generate and manipulate droplets in high-throughput screening, single-cell analysis, and chemical synthesis. PMMA’s compatibility with various fluids and its hydrophobic nature allow for precise droplet generation and control.

- Organ-on-a-chip: PMMA’s transparency facilitates real-time observation and analysis of organ-on-a-chip models.

- Environmental monitoring: such as water quality analysis and pollutant detection. PMMA devices can integrate sensors and detection methods to analyze samples and provide rapid and portable testing solutions.

- Microreactors: PMMA devices can be used as microreactors for chemical reactions at the microscale. These microreactors enable precise control of reaction conditions, enhanced mixing, and reduced reaction times. PMMA’s chemical resistance and ease of fabrication make it suitable for creating microreactor systems.

Overall, PMMA is a well-known material for mass production and, therefore, very easy to manufacture on a large scale. Thus, if you want to go through a prototyping phase for all these applications before possibly considering more significant production, it must be a suitable material for your requirements!

Examples of PMMA chips

Technical specifications

Laminator: An easy-to-use hot and cold laminator

| Components | Specifications |

|---|---|

| Dimensions | 500*200*100mm |

| Laminating speed | 560mm/min |

| Max laminating thickness | 1mm |

UV lamp: A functional exposure-masking chamber operating with a cold UV source with pattern resolutions down to 1µm

| Components | Specifications |

|---|---|

| Dimensions | 260*260*260mm |

| Wavelength | 365nm +/- 5 nm |

| Max substrate thickness | 2mm |

Heat plate: A programmable hot plate with a smooth temperature ramp

| Components | Specifications |

|---|---|

| Dimensions | 203*203mm |

| Max temperature | 450℃ |

| Temperature accuracy | 1% |

Heat press with double heating plate:

| Components | Specifications |

|---|---|

| Dimensions | 420*550*680mm |

| Max temperature | 300℃ |

| Pressure range | 0-25 tons |

Oven: A conventional laboratory oven

| Components | Specifications |

|---|---|

| Dimensions | 150L |

| Max temperature | 250°C |

Optional

- Ultrasonic bath

- Drilling machine

Customize your pack

Our Packs can be modified depending on your specific needs. Our microfluidic specialists will advise you to provide the best instruments and accessories, depending on your needs. They will accompany you during the setup of the microfluidic platform.

Frequently asked questions

Can I order a pack?

Our Packs, such as the Live Cell Imaging pack, are available under specific conditions. As these packs are still in the developmental stage, we have some eligibility criteria to ensure their optimal success rate.

At the Microfluidics Innovation Center, we tailor our approach to suit each researcher’s unique needs. Therefore, before purchasing a Pack, we encourage you to contact our technical team for a detailed discussion of your research objectives and requirements.

To learn more about our Packs or to schedule a consultation with our experts, please contact us using the “talk to our experts” green button above. We look forward to collaborating with you and supporting your research endeavors.

Can I buy individual instruments?

You can order our instruments on the product section of our website.

Funding and Support

The BIOPROS and MICRO4NANO project results helped develop this instrument pack, with funding from the European Union’s Horizon research and innovation program under HORIZON-CL4-2021-DIGITAL-EMERGING-01-27, grant agreement no. 101070120 and the European Union under H2020-MSCA-RISE-2020, grant agreement No. 101007804.

Special thanks to Micaela Fernandes and Widad Mesbahi, who largely contributed to the development of this pack.

Products & Associated Accessories

PMMA device station

What is the PMMA Device Station?

PMMA Device Station is a complete application bundle for autonomous PMMA microfluidic chip fabrication, from mold development to the creation of high-resolution devices. It allows scientists to design microfluidic systems, Bio-MEMS and other applications without microfabrication experience and the chips are fabricated within 5 hours or so.

What are the main benefits of PMMA as a microfluidic device material?

PMMA is associated with a number of advantages:

-Quick process of fabrication (less than 5 hours)

-High-resolution devices without specialized microfabrication knowledge

-Highly reproducible processes with reusable molds

-Low-cost production.

-Adequate for use under high pressure.

-Good to scale to mass production.

Which is better, PMMA or PDMS, to use in microfluidics?

PMMA advantages:

-Hard structure that is capable of working under high pressure.

-Low gas permeability

-Enhanced reaction with solvents and reagents.

-Moderate to high UV radiation resistance.

-Better for scale-up and mass production.

PDMS advantages:

-Flexible and elastomeric

-High gas permeability

-Soft lithography has made prototyping easier.

-Surface of natural hydrophilicity.

-Less complicated connection possibilities (direct tubing insertion).

General Instructions: PDMS is much easier to prototype and work with at low pressure; PMMA is better for high-pressure work and scale production.

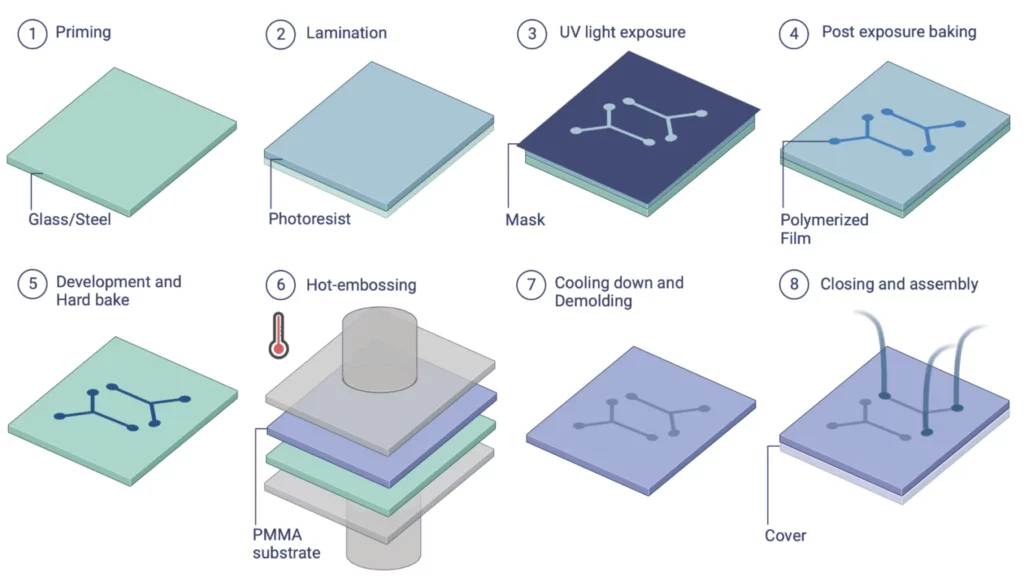

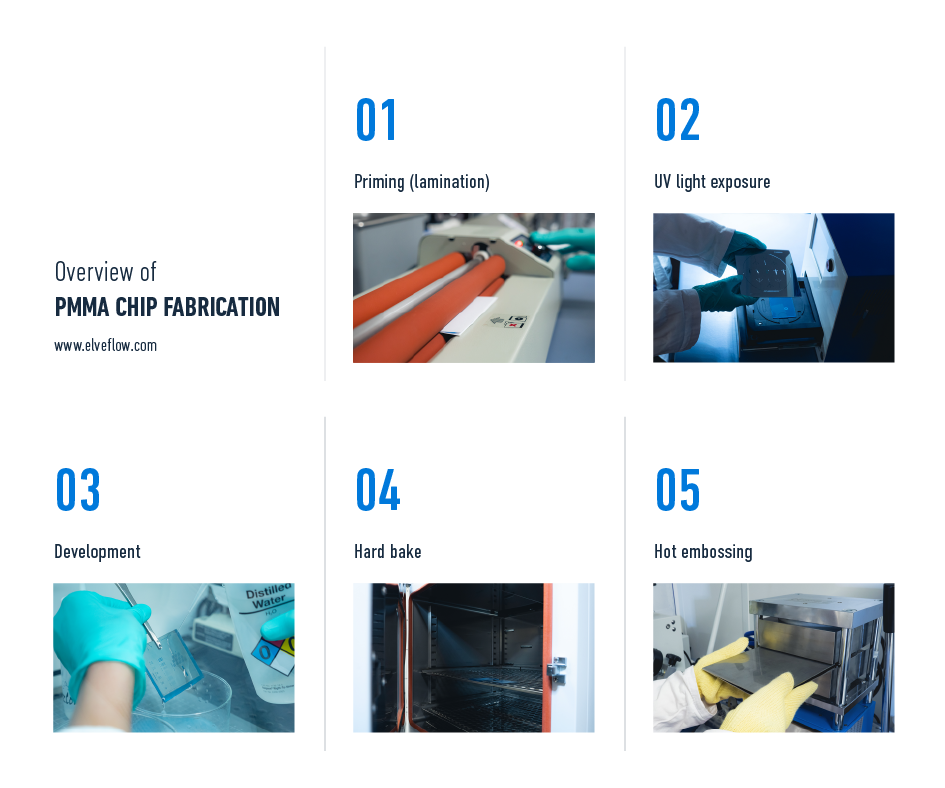

How does the PMMA chip fabrication work?

The production of the master moulds is followed by the replication of PMMA:

-Mold fabrication: Place dry photoresist film, UV exposure using photomask, develop pattern (down to 1um resolution)

-Embossing PMMA: Heat-press stamps a pattern on the PMMA film.

-Bonding: Thermal bonding, solvent bonding, or plasma treatment.

-Finalizing: Drilling ports, external connector.

-Total time: Less than one day, operation chips in 5 hours or so.

What devices can be used in applications of PMMA?

The transparency, the recyclability and biocompatibility of PMMA allow various applications:

-Biomedical research: Cell culture, drug discovery, DNA testing, protein, point of care diagnostics.

-Droplet microfluidics: High-throughput screening, single cell analysis, chemical synthesis.

-Organ-on-a-chip: Tissue models in real-time.

-Water quality analysis, pollutant detection Environmental monitoring.

-Microreactors: Chemical reactions in microscopic quantities and control.

What are the major technical specifications?

-Laminator: 500x200x100mm, 560mm/min speed 1mm maximum thickness.

-UV lamp: chamber of 260x260x260mm, 365nm wavelength, pattern resolution of 1um.

-Heat press: 420x550x680mm, 0-25 ton pressure range, to 300 °C.

-Oven: 150L capacity, up to 250 °C

Who is responsible for placing an order for the PMMA Device Station?

The packs can be obtained under certain conditions because they are still in development. Researchers must contact the technical team for:

-Discussion of research objectives.

-Evaluation of eligibility requirements.

-Discussion on ideal setup.

-Checking of pack suitability towards the applications.

-The product section also allows individual instruments to be bought separately.