COC Polymer Molding Microfluidics Setup

From PDMS to low-impurity high-performance COC polymer

Fast process

Fabricate plastic COC chips in only 1 hour

No clean room required

The entire microfabrication process takes place outside of a clean room

Adaptable to your needs

Easily shaped into any form or dimension

Need a microfluidic SME partner for your Horizon Europe project?

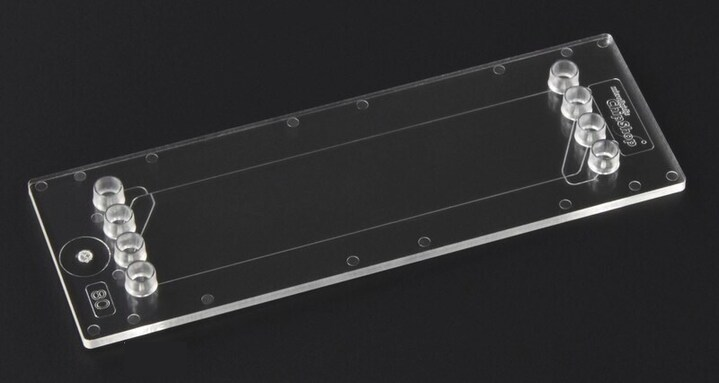

COC polymer molding microfluidics setup

From manufacturing PDMS chips …

The most common material for microfluidic device fabrication is PDMS.

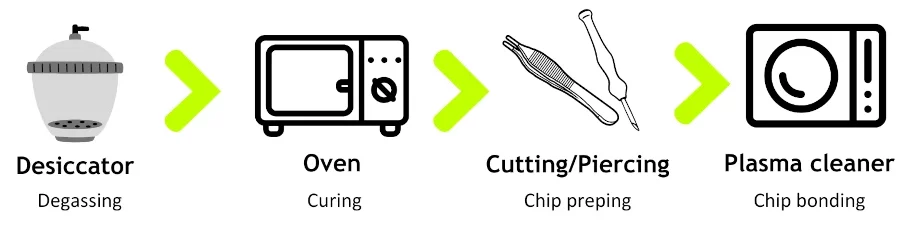

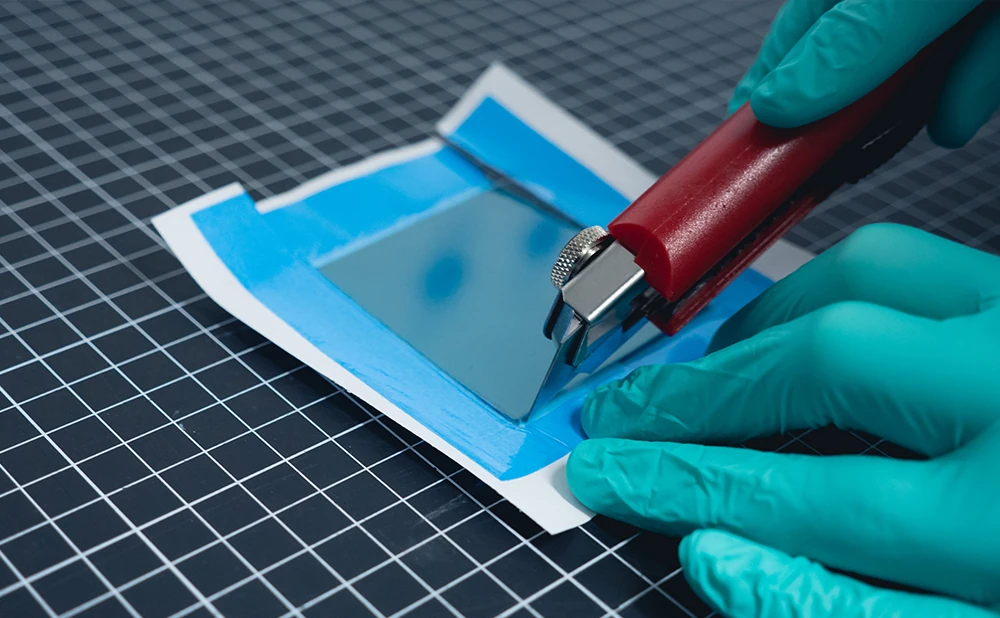

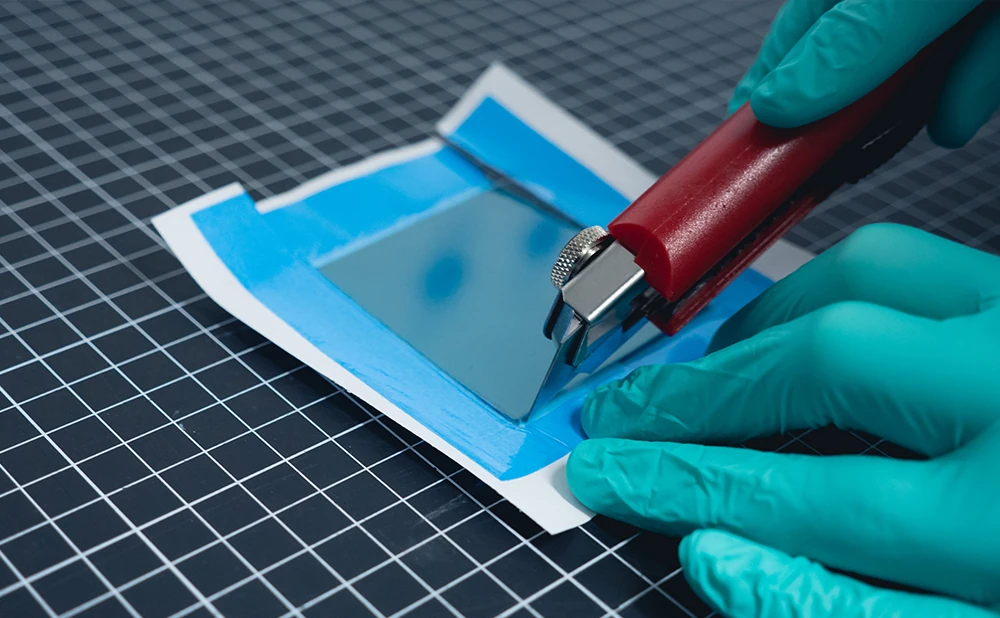

PDMS chip fabrication takes place outside a clean room. It starts by mixing PDMS with a curing agent and degassing it in a desiccator. Then, it is poured onto a mold and cured in a standard oven. Once cured, the chips are demolded, precisely cut, and have inlet holes created using biopsy punchers. Finally, plasma cleaner treatment firmly sticks the PDMS to a glass slide.

Yet, PDMS’s limited chemical compatibility, high gas permeability, and low throughput hinder its use in many critical applications. That is why researchers are shifting towards alternative materials such as cyclic olefin copolymer (COC) plastic.

… To COC polymer molding!

Plastic COC provides many advantages for chip microfabrication. It is noted to be a high purity product with excellent optical properties. It is biocompatible and exhibits high chemical resistance. Its moisture insensitivity and gaz permeability can turn out to be real assets in many applications. Furthermore, its ease of fabrication and modification offers a great versatility of design.

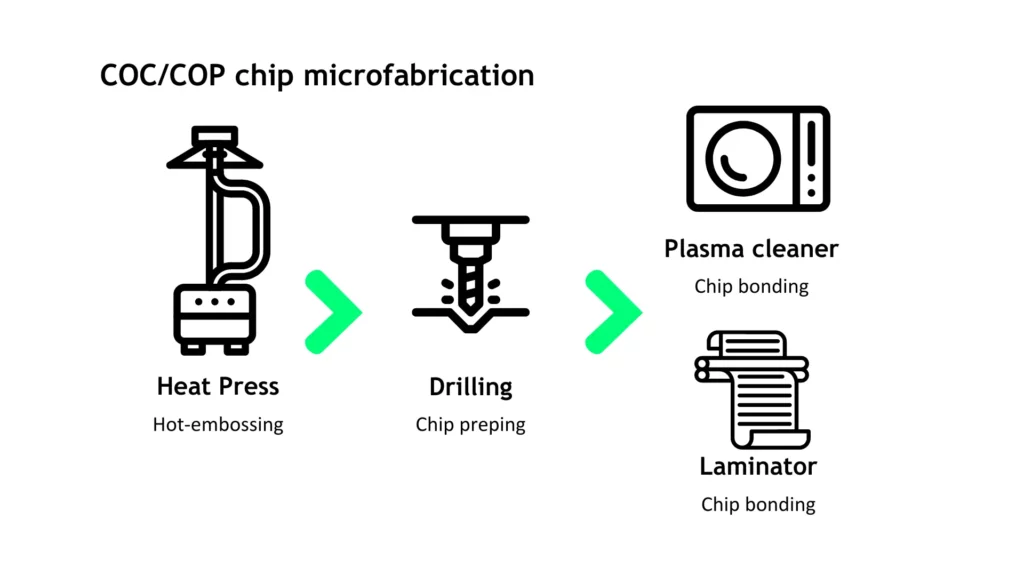

Microfabrication of COC polymer follows the same steps as for the thermoplastic chip microfabrication, and both can be performed outside of a clean room. Our setup is also compatible with the homopolymer COP.

By following our instructions and adding the recommended heat press and laminator, you can smoothly shift from PDMS microfabrication to a COC polymer molding setup.

Your PDMS microfabrication process is different, and you don’t have all the listed equipment? Don’t worry; we’ve got you covered! We can provide you with all the necessary pieces and consumables; just drop us a line!

We recently published a review about the diverse materials and innovative fabrication and molding techniques used in microfluidic chip design.

Compatibility and applications

The COC polymer molding setup can also be used with:

PMMA device station

From mold development to high-resolution PMMA chip fabrication

✓ Fast process

✓ Multiple applications

✓ Simple and innovative setup

PMMA

Polystyrene (PS) molding microfluidics setup

From PDMS to highly versatile and transparent Polystyrene PS

✓ Fast process

✓ No need for a clean room

✓ High versatility

Polystyrene

Polycarbonate (PC) molding microfluidics setup

From PDMS to highly versatile and performant Polycarbonate PC

✓ Fast process

✓ No need for a clean room

✓ High impact strength

Polycarbonate

And many more!

Microfluidic chips produced with COC polymer molding can be employed in:

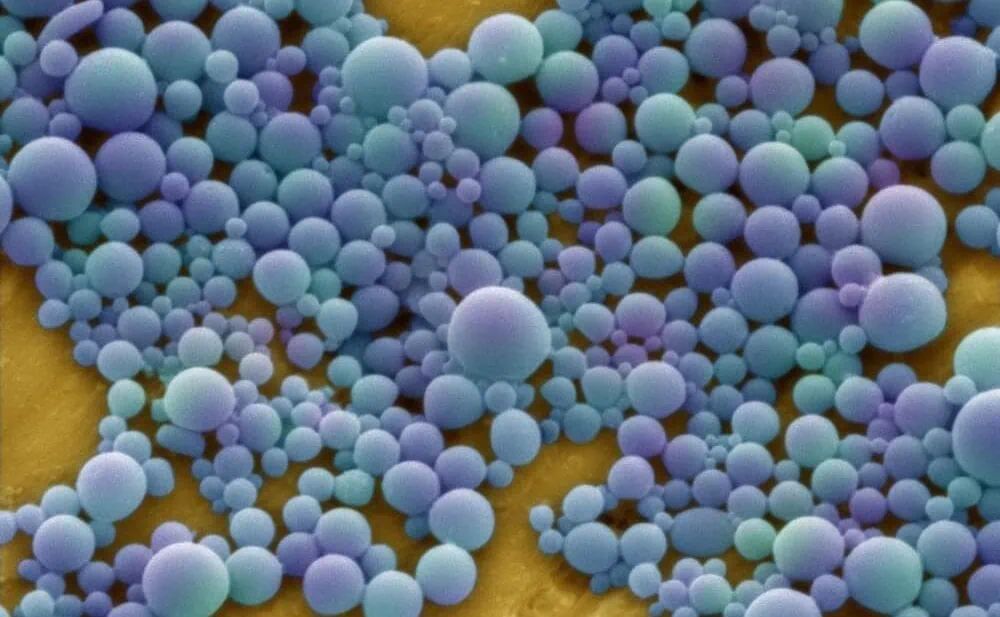

Microfluidics nanomaterial synthesis pack

Microfluidics for production of nanomaterials using sheath flow focusing

✓ Efficient synthesis. ofnanomaterials

✓ Easy microfluidic system implementation

✓ Biomedical applications

Lab-on-a-chip applications (e.g. nanomaterial synthesis)

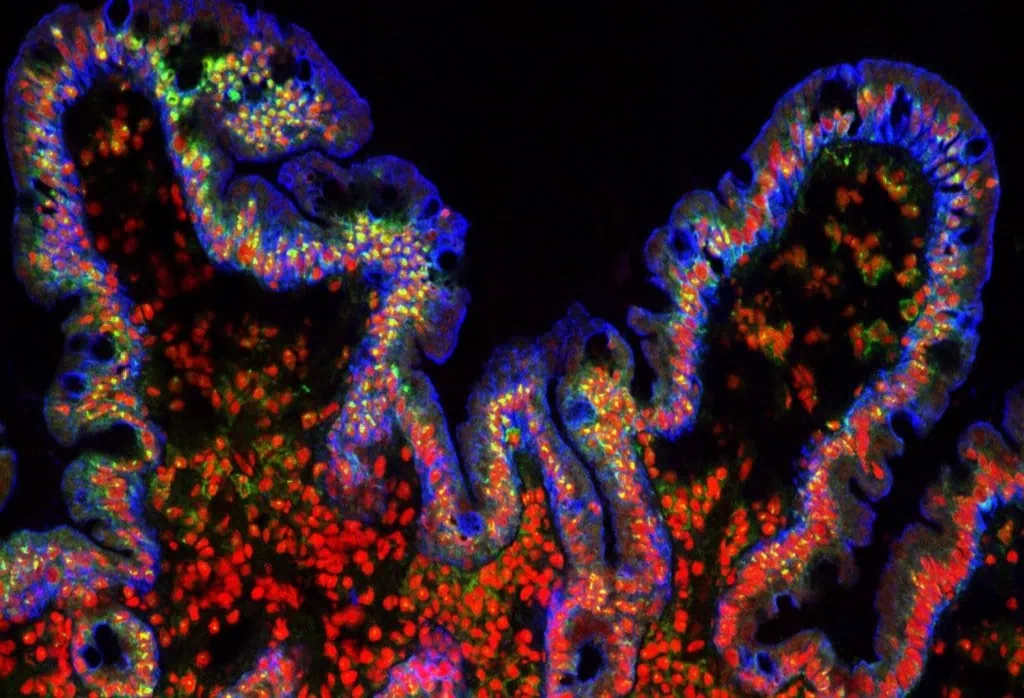

Gut-on-a-chip pack

Intestinal cells coculture under flow, mimicking the gut physiology

✓ All microfluidic pieces included, quick and easy assembly

✓ Dynamic culture conditions

✓ Advanced in viro/ex vivo

Gut-on-chip

Applications requiring specific-chip design and chemical inertia

And many more!

Technical specifications

The COC polymer molding microfluidic setup comprises:

Heat press with double heating plate

| Components | Specifications |

|---|---|

| Dimensions | 420*550*680mm |

| Max temperature | 300 °C |

| Pressure range | 0-25 tons |

Laminator

| Components | Specifications |

|---|---|

| Dimensions | 270*545*130 mm (L x w x h) |

| Max laminated width | 335 mm |

| Max laminated thickness | 35 mm |

| Max temperature | 140 °C |

Options: Drilling machine

Consumables: Plastic COC sheets

Frequently asked questions

Does the process also involve mold fabrication?

Currently, the COC polymer molding microfluidic setup focuses on the chip fabrication and bonding from a pre-existing mold. However, we do have expertise to advise you in how to make your own molds.

What is the resolution of the COC microfluidic devices?

Resolutions as low as 15 µm (channel width) for an aspect ratio of 2:1 can be achieved.

What maximum pressure can the devices withstand?

Based on internal testing, up to 3.5 bar.

What material can I use to close the chip?

The chip can be closed with a thermoplastic slide, a microscope glass slide or a microscopy-compatible polymer slide.

Is this process compatible with microscopy/reversed microscopy?

COC polymer offers exceptional transparency, and is very well suited for microscopy!

Funding and Support

The BIOPROS and MICRO4NANO projects results helped develop this instrument pack, with funding from the European Union’s Horizon research and innovation program under HORIZON-CL4-2021-DIGITAL-EMERGING-01-27, grant agreement no. 101070120 and the European Union under H2020-MSCA-RISE-2020, grant agreement No. 101007804.

Products & Associated Accessories

FAQ - COC polymer molding microfluidics setup

What is the issue a COC polymer molding system is intended to address, that a standard PDMS workflow does not?

PDMS is user-friendly with some trade-offs beginning to take their toll once you get outside the quick prototyping domain: has poor chemical compatibility, is highly permeable to gases and quite low throughput. An olefin copolymer (COC) fabrication process maintains the no cleanroom ethos of the PDMS fabrication, but uses a more pure thermoplastic, biocompatible, and usually much more chemically resistant- making it closer to what you would desire in an assay, longer experiment, or translationally-oriented prototype.

What is the actual rate of the process? Is “1 hour” realistic?

The workflow will produce plastic COC chips within the span of about 1 hour (molding to a sealed device) provided that you already have your mold set and your consumables (COC sheets, sealing substrate, and so on) ready. The time savings is primarily achieved by substituting PDMS mixing/degassing/curing with a heat-press hot-embossing step followed by simplifying access ports by using a drilling tool and sealing by using a laminator and a plasma treatment as required.

Is any stage of the fabrication in a cleanroom required?

No, this is a system that is intended to operate outside a cleanroom. It can typically be one of the large practical successes of European academic labs and SMEs: it is possible to remain in microfabrication without making the project a facilities-management project.

What devices are involved (or needed) in the COC polymer molding microfluidics apparatus?

Core elements are:

-Heat press has two heating plates (hot embossing)

-Max temperature: 300 °C

-Pressure range: 0-25 tons

-Dimensions: 420 x 550 x 680 mm

-Laminator (is used to seal / close steps based on which stack was chosen)

-Max temperature: 140 °C

-Max laminated width: 335 mm

-Max laminated thickness: 35 mm

-Dimensions: 270 x 545 x 130 mm (L x W x H)

-Common choices/nearby instruments: a drilling machine when you need inlets/outlets, the conventional of microfluidics (alignment habits, cleaning, and usually plasma treatment should you be bonding to some substrates).

Does this installation involve the fabrication of moulds or do I have to bring my own mould?

The system is aimed at making the chip and bonding it to an existing mold. MIC can however give you help on how to create your own molds in case you are starting off scratch (and, practically, a strategy of mold is where many projects end up being either elegant or agonizingly slow, so it is worth considering doing it at an early stage).

What size can I get more? “real microfluidics” or more millifluidic-like channels?

It is possible to achieve channel width of 15 um (reported at aspect ratio of 2:1). Stated otherwise: well, this is strictly speaking microfluidics, not simply completely grooves in plastic. As usual, your effective limit will be determined by the quality of the mold, the embossing characteristics and your ambition with regard to aspect ratio and demolding.

To what pressure level can these devices be exposed?

Devices have the ability to sustain up to 3.5 bar based on internal testing. That is a convenient number when you need to do perfusion under flow or recirculation or any arrangement where backpressure is not an afterthought.

What is the method of closing (sealing) the COC chip, what substrates can be used?

Closing is not vested in any way. You can seal the chip with:

-a thermoplastic slide,

-a normal microscope glass slide, or

-a polymer slide that can be used in microscopy.

This is important than it sounds: it allows you, depending upon a particular experiment, to choose between optical performance, mechanical robustness, or chemical resistance.

Does COC work with microscopy including inverted microscopy?

Yes. COC is said to have outstanding transparency, and it can be easily microscoped, including inverted. To a good fraction of users transitioning off of PDMS, the transition is positively unexpected: the imaging environment remains good, and there is an improvement in chemical durability and reduced impurity issues.

Can the same be extended to other thermoplastics (or COP) other than COC?

Yes. The logic of fabrication is based on a wider-range thermoplastic microfabrication and can also be used with the homopolymer COP. In case your application drives you to another thermoplastic (e.g., polystyrene, polycarbonate, PMMA), MIC also places related configurations in the category of an adjacent option, which may be helpful when your requirements are dictated by solvent exposure, mechanical toughness, or assay compatibility.

What are the research use-cases that are best suited to this setup?

A few recurring ones:

-Systems where laboratories do work on a chip, such as the synthesis of nanomaterials (purification and chemical stability of materials are important).

-Flow cell culture (organ-on-a-chip style experiments, gut-on-a-chip type co-cultures), in which stable perfusion and imaging is required.

-Any design requiring particular chip layouts and chemical inertia (i.e. you do not want the chip to be the variable).

-COC can often be a reasonable compromise in the event you want prototypes that are more like scalable manufacturability than the PDMS usually induces.