Biofuel Production Pack

Accelerating algae culture optimization with microfluidic flow control

Stable delivery

Controlled input of key nutrients

Live monitoring

Real-time flow and lipid tracking

Fast testing

Run multiple conditions in parallel

Need a microfluidic SME partner for your Horizon Europe project?

Redefining algae cultivation for biofuel research

Algae hold immense promise for sustainable biofuel production thanks to their fast growth and high lipid output [1]. Yet, finding the ideal growth conditions remains a critical challenge for researchers aiming to scale [2].

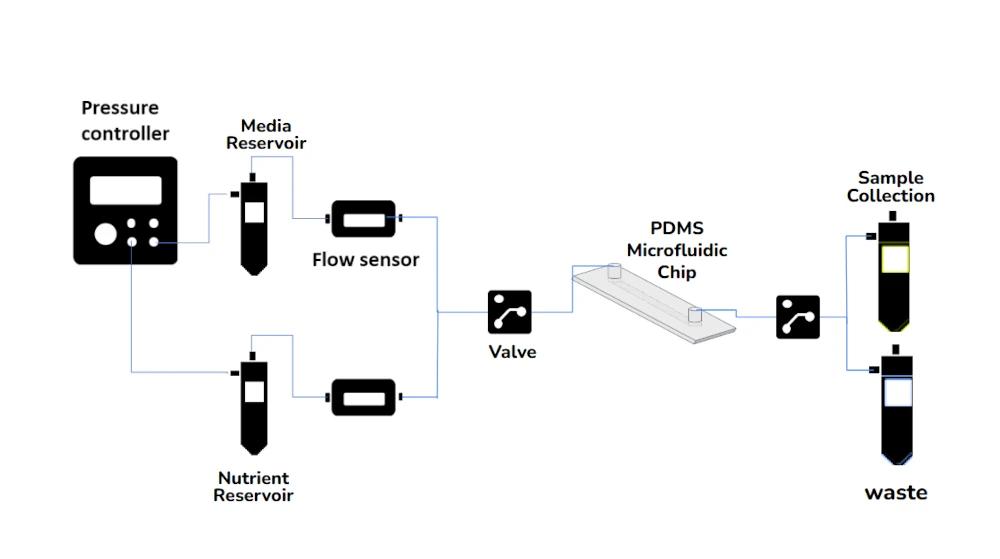

The biofuel production pack is engineered to streamline culture optimization workflows by bringing microfluidic control and real-time data together [3]. Central to this setup is the pressure pump for microfluidics, a high-precision, pulsation-free pressure system that offers smooth and programmable flow across multiple channels. This enables researchers to deliver nutrients with consistency and run parallel tests across different conditions [3].

Coupled with the Galileo flow sensor, users can monitor nutrient delivery and detect real-time changes in flow, allowing for immediate insight into how the algae respond to shifts in inputs or stress factors. The system mimics bioreactor dynamics within a compact, flexible setup, accelerating the discovery of optimal cultivation strategies [4].

Algae for biofuels, Credit: Oak Ridge National Laboratory, Wikimedia commons

Setup

Pressure pump for microfluidics

Galileo flow sensor

Automated sampling system (optional)

Liquid reservoir (likely water or growth media)

Nutrient reservoir

Waste reservoir

Sample collection reservoir

Microfluidic chip (PDMS/Glass-based – microfluidic chipshop)

Reference

Image:

Biofuel picture from La Jolla, Wikimedia commons.

Text:

Zhang, Y., et al. (2017). Microfluidic systems for microalgal biotechnology: A review.

Liu, F. et al. (2023). Colimitation of light and nitrogen on algal growth revealed by an array microhabitat platform.

Wang, Y., et al. (2018). Microfluidic techniques for enhancing biofuel and biofinery production.

Chen, Y., et al. (2022). Application of microfluidics for revealing physiological metabolic characteristics of microalgae: A review.

Microfluidic flow sensor technical specifications

| Pressure control | |

|---|---|

| Pressure | -400 to 600 mbar |

| Pressure stability | 0.2 mbar |

| Air flow rate | 0.1 L/min at atmospheric pressure Possibility to work with higher air flow rates by reducing the pressure range |

| Pressure control | |

| Microfluidic flow sensor | Monitoring and feedback loop flow control available |

| Flow rates | From 0.1 µL/min to 5 mL/min |

Pressure pump technical specifications

| Pressure control | |

|---|---|

| Pressure range | 0 to 2000 mbar |

| Accuracy | 2.5 mbar |

| Gas consumption | Close to liquid flow rate |

| Response time | 50 ms |

| Settling time | around 1s |

| Flow control | |

| Flow rate | from 0.4 to 1000 µL/min |

| Flow rate accuracy | 5% Read value |

Compatibility and applications

- Culture optimization

Fine-tune growth conditions for maximal lipid production. - Biofuel R&D

Screen algae strains for fuel potential under dynamic environments. - Carbon capture studies

Explore algae’s efficiency in converting CO₂ into biomass. - Synthetic biology

Test engineered strains under highly controlled flow and nutrient regimes. - Sustainable resource utilization

Evaluate alternative growth substrates (e.g., agri-waste) in closed-loop systems.

Frequently asked questions

What makes this pack ideal for algae culture optimization?

It provides precise, programmable nutrient delivery and real-time monitoring, allowing researchers to efficiently test and refine growth conditions.

Can I monitor the culture’s behavior in real time?

Yes. The Galileo Flow Sensor continuously tracks flow dynamics, helping detect clogging, nutrient depletion, or system drift early.

Is this setup scalable for industrial biofuel development?

While designed for lab-scale use, the pack simulates bioreactor conditions, making it ideal for pre-scaling culture strategies.

How can we help your experiment?

This pack is in beta testing phase. So, although the instruments are not fully industrialized, we can provide extensive support as part of our beta testing program. Get in touch to see if you are eligible.

Funding and Support

This project has received funding from the European Union’s Horizon research and innovation program under HORIZON-EIC-2023-PATHFINDEROPEN-01, grant agreement no. 101130747 (Bio-HhOST).

The development of the Galileo flow sensor has received funding from the European Union’s Horizon research and innovation program under HORIZON-EIC-2022-TRANSITION-01, grant agreement no. 101113098 (GALILEO).

Products & Associated Accessories

FAQ - Biofuel production pack

What does the Biofuel Production Pack mean?

This is a microfluidic application pack developed by the Microfluidics Innovation Center to optimize algae culture development faster to support biofuel studies. The system unites microfluidic flow control and real-time data to simplify processes of culture optimization.

What are the essential capabilities of the pack?

The pack will be constructed based on three functions:

Constant delivery: A high-precision pulsation-free pressure system provides a stable input of major nutrients and offers smooth flow with multiple channels, which is programmable.

Live monitoring: Galileo Flow Sensor constantly measures flow dynamics, allowing to prevent the clogging or loss of nutrients or drift of the system in time.

Fast, parallel testing: The researchers are able to test a number of conditions in parallel, and they are able to directly compare various cultivation parameters in one experiment.

What are the instruments and components of the pack?

Its basic configuration comprises of a pressure pump to microfluidics and Galileo flow sensor together with an automated sampling setup as an optional extra. On the consumables side, the device needs liquid and nutrient, waste, sample collection and PDMS/glass-based microfluidic chip.

What will be in the pack and what will be optional?

Core building blocks are:

A programmable, multi-channel style control pulsation-free pressure pump in microfluidics.

A flow sensor of Galileo to monitor the flow in-line (and provide the feedback-loop control in case of close loop stability).

A microfluidic chip (the page lists the options of PDMS/glass chips; once is generally purchased via a microfluidics chip supplier).

Optional:

An automated sampling system ( handy when you need to be hands-off in collecting fractions or time-resolved sampling without monitoring the system)

What does experimental meaning of the page that reads real-time lipid tracking mean?

In practical terms, it implies that the platform will be engineered in such a way as to allow stable perfusion + flow telemetry and whatever lipid readout you happen to favor (e.g. optical/fluorescence-based lipid staining, microscopy readouts or other in-line analytics that you already trust). The sensor itself is a Galileo sensor, which is actually concerned with the flow; the lipid part is the layer which you add on top of the sensor, which means that you are not committed to one philosophy of detection.

What are the major technical specifications?

With the pressure pump, pressure is between 0 and 2000 mbar, response time is 50 ms and flow rate is between 0.4 and 1000 uL/min with a 5 percent read value error.

In case of the Galileo flow sensor, the flow rates that can be supported vary between 0.1 uL/min up to 5 mL/min and a feedback loop flow control can be monitored.

Can this pack be scaled to industrial scale production of biofuels?

Not directly so, but in such a way that it is intended to inform that process. The pack is lab-scale simulated, although it has been used to model bioreactor conditions, which is why it is preferable to pre-scaling culture strategies.

Status of the pack? and support provided?

The pack is at the stage of beta testing. The instruments are not quite industrialized, but there is extensive support included in the beta testing program. Researchers who may be interested in joining can directly approach the Microfluidics Innovation Center to enquire about qualification.

How is this project funded?

It is funded by the European Union, Horizon research and innovation program under HORIZON-EIC-2023-PATHFINDEROPEN-01 (Bio-HhOST) and the development of the Galileo flow sensor was funded under HORIZON-EIC-2022-TRANSITION-01 (GALILEO).