Cell Perfusion with Oxygen Control

Control the oxygen of your dynamic cell culture continuously

Plug in your pre-mixed gas bottle

Pressurize your media with the desired oxygen concentration

Versatile

Compact and portable pump

Stable long-term flow

Stable flow in the physiological profiles of your choice

Need a microfluidic SME partner for your Horizon Europe project?

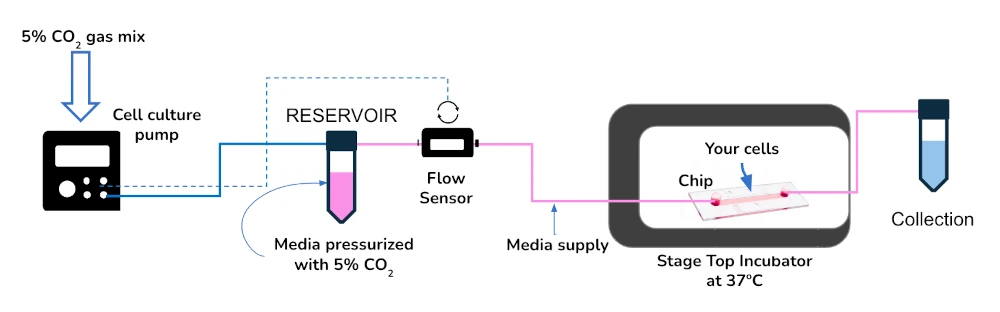

Oxygen control setup

We have assembled all the components to perform successful perfusion with continuous O2 control. The setup displayed below is meant to continuously and stably perfuse media in a highly controlled microenvironment: a pre-mixed gas bottle is plugged into the cell culture pump, pressurizing the reservoirs with the correct mix of gasses for your experiment; temperature is kept by a stage top incubator that allows for long-term live cell imaging with ease.

The cell culture oxygen pack contains:

Flow sensor (Galileo, MIC)

Software (Galileo user interface)

Cell culture pump

Stage top incubator

Microfluidic chip (application-dependent; suggestion ibidi µ-Slide I Luer)

Fittings, tubings, luers

Reservoirs

User guides for instruments

This instrument can also be adapted to our automated cell culture platform.

For applications requiring fluid injection to test the effects of drugs, for example, a rotary valve or a check valve recirculation bridge can be added to the setup. Check out our automated recirculation system and this application note that explains how to assemble the recirculation bridge.

Oxygen levels in dynamic cell culture

Adequate microenvironment parameters are crucial for a thriving cell culture. Oxygen in the cell culture is one of the parameters that must be surveyed to ensure healthy cell growth and division.

However, it is rarely monitored in traditional cell culture flasks since it is assumed that the oxygen from the atmosphere will diffuse into the media at sufficient rates.

On the other hand, dynamic cell cultures are closed-loop systems in which the changes in concentration of essential parameters, such as oxygen, are more pronounced due to the minute volumes. Therefore, they require closer monitoring and surveillance.

Applications

Red blood cell studies

Oxygen supply for gas impermeable chips

Effects of oxygen concentration on cell viability and gene expression

And many more!

Chip compatibilities

PMMA device station

From mold development to high-resolution PMMA chip fabrication

✓ Fast process

✓ Multiple applications

✓ Simple and innovative setup

PMMA

Homemade devices, PDMS

Synvivo

Microfluidic ChipShop

And many more!

Oxygen control pack specifications

The Oxygen control pack contains a set of instruments for continuous cell culture perfusion and monitoring. The cell culture pump controls the fluid flow.

The table summarizes the main specifications of the Oxygen control system.

| Components | Technical Specifications |

|---|---|

| Cell culture pump | 4 Channels (0 to 2000 mbar) |

| Microfluidic flow sensor (eg. Galileo) | Range from 0.5 to 10,000 µL/min |

| Cell culturing chamber | Microfluidic chips (2.55 x 7.55 cm) |

| Stage top incubator | 0 to 70oC; k-frame bottom |

Customize your pack

Our instruments can be added to highly customizable setups, so you can take advantage of the extra flexibility to adapt them depending on your specific needs. Our microfluidic specialists will advise you on the best instruments and accessories depending on your needs and will accompany you during the setup of the microfluidic platform.

Our instruments are compatible with standard commercialized chips from different brands.

Frequently asked questions

Is the setup sterilizable?

The reservoirs and tubings are disposable but can be sanitized with a cleaning protocol. The flow sensors can also be sanitized with the same protocol. Connectors can be autoclaved.

Can I do anaerobic/hypoxic experiments with this setup?

For example, you can plug a nitrogen bottle into the cell culture pump to pressurize a deoxygenated media. However, the gas permeability of the tubing and the gas tightness of the fluidic system connections must be considered to ensure no oxygen permeates into the system during the experiment.

Can the pump be placed in the CO2 incubator?

The gas control pump should be kept outside the CO2 incubator. The flow sensors can be placed inside the incubator.

Can it measure the oxygen concentration in the media?

Currently, the pump can only control the gas composition based on the pre-mixed gas input supplied. It is advisable to add oxygen sensors to the microfluidic circuit or chip if there’s a need to measure the precise concentration of oxygen.