Flow Photochemistry Instrument Pack

Long microfluidic meander channel perfect for continuous flow photochemistry

High residence time

Long fluid path length for high residence time reactions

Short light path distance

100 µm channel depth for efficient irradiation

Small compact footprint

Standard microscope slide format

Need a microfluidic SME partner for your Horizon Europe project?

Microfluidic continuous flow photochemistry pack

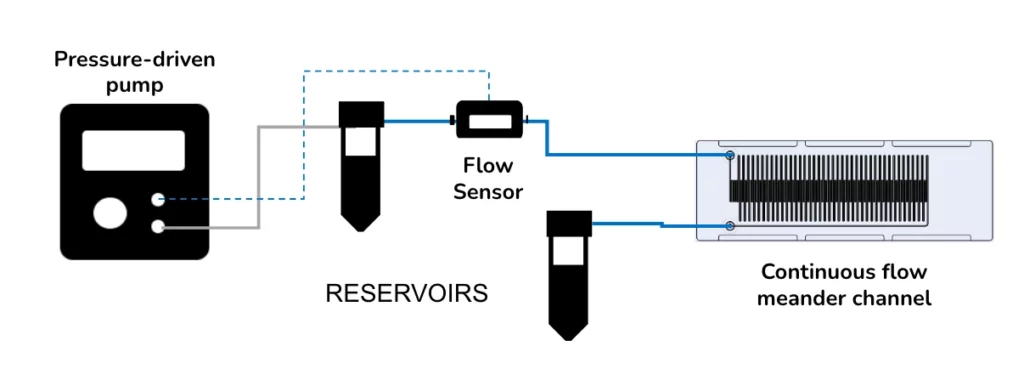

Based on the high-accuracy a pressure-driven flow controller and a meander channel chip, this plug-and-play solution contains all the required parts to establish flow photochemistry reactions quickly.

The standard continuous flow photochemistry pack contains a single pumping channel to push the reaction fluid through the meander channel chip, creating a long fluid path and residence time.

The short 100 µm channel depth allows fluid irradiation to occur far more efficiently than batch methods or tubing-based microreactors.

Flow rates can be measured thanks to a microfluidic flow sensor (eg. Galileo). Fix a light source above the channel, press a button to start pumping, and conduct the flow photoreactions. This experiment is both easy to set up and efficient.

Flow photochemistry pack setup

This pack guarantees good compatibility between its components, which are piloted by a single software. The provided instruments are easy to use, and a complete user guide and accessories are included.

A typical flow photochemistry pack contains:

Flow sensor (Galileo, MIC)

Software (Galileo user interface)

Flow controller

2 x 15 mL reservoirs

Microfluidic chips from microfluidic ChipShop

All necessary accessories: tubing, connectors, filters, etc…

Microfluidic continuous flow photochemistry principle

The meandering channel that can be included in the flow photochemistry pack, also known as a serpentine channel, is a simple channel designed to take advantage of the microfluidic chip format to fit a long fluid path length into a small area.

With a long fluid path length, long residence times when reagents are inside the microreactor are made possible while maintaining moderate to high flow rates for high throughput reactions. This format has enabled a wide variety of flow chemistry reactions [1–4], particularly photoreactions [5–7], showing significantly improved reaction rates compared to in batch.

References

1. K. S. Elvira, X. C. i Solvas, R. C. R. Wootton, and A. J. DeMello, “The past, present and potential for microfluidic reactor technology in chemical synthesis,” Nat. Chem., vol. 5, no. 11, pp. 905–915, 2013.

2. R. Porta, M. Benaglia, and A. Puglisi, “Flow Chemistry: Recent Developments in the Synthesis of Pharmaceutical Products,” Org. Process Res. Dev., vol. 20, no. 1, pp. 2–25, 2016.

3. D. M. Ratner, E. R. Murphy, M. Jhunjhunwala, D. a Snyder, K. F. Jensen, and P. H. Seeberger, “Microreactor-based reaction optimization in organic chemistry–glycosylation as a challenge.,” Chem. Commun. (Camb)., 2005.

4. J. S. Moore and K. F. Jensen, “Automated Multitrajectory Method for Reaction Optimization in a Microfluidic System using Online IR Analysis,” Org. Process Res. Dev., vol. 16, no. 8, pp. 1409–1415, Aug. 2012.

5. T. Fukuyama, Y. Hino, N. Kamata, and I. Ryu, “Quick Execution of [2+2] Type Photochemical Cycloaddition Reaction by Continuous Flow System Using a Glass-made Microreactor,” Chem. Lett., vol. 33, no. 11, pp. 1430–1431, Nov. 2004.

6. R. A. Maurya, C. P. Park, and D.-P. Kim, “Triple-channel microreactor for biphasic gas–liquid reactions: Photosensitized oxygenations,” Beilstein J. Org. Chem., vol. 7, pp. 1158–1163, Aug. 2011.

7. C. P. Park, R. A. Maurya, J. H. Lee, and D.-P. Kim, “Efficient photosensitized oxygenations in phase contact enhanced microreactors,” Lab Chip, vol. 11, no. 11, p. 1941, 2011.

Why use microfluidics for flow cytochemistry?

Moreover, microfluidic precision allows for the rapid fine-tuning of reaction parameters, allowing for efficient reaction optimization at reduced time and reagent consumption compared to batch methods.

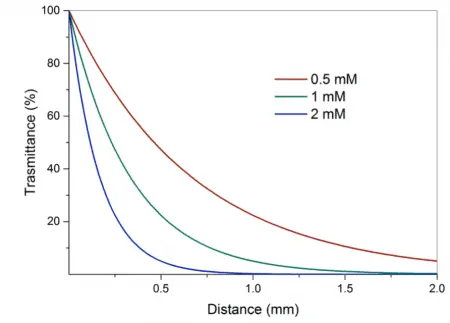

The small light path distances in microfluidic channels allow for high homogeneity solution irradiation. Inhomogeneity in irradiation is a common problem in batch photochemistry (see the Figure below) due to millimeter-scale light paths. Greater irradiation homogeneity from flow photochemistry can allow higher throughput reactions and more excellent reaction selectivity.

Micrometer scales in microfluidic chips also allow reactions with greater thermal homogeneity thanks to the high surface-area-to-volume ratios. This will significantly increase the heat transfer in microreactors, which can also help improve reaction selectivity.

Finally, microfluidic chip reactors allow for significant reaction path length while maintaining a small footprint compared to a comparable tubing-based microreactor, much less batch reactors.

References

1. Cambié, D., Bottecchia, C., Straathof, N. J. W., Hessel, V., & Noël, T. (2016). Chemical Reviews, 116, 17, 10276–10341.

Customize your flow photochemistry pack

Depending on your specific application, the microfluidic flow photochemistry pack can be exceedingly personalized. For example, supplementary pumping channels for the OB1 flow control pump and flow rate sensors can be added to the pack to inject different solutions inside the microfluidic chip.

The meander channel chip provided by Microfluidics ChipShop is available in Cyclo Olefin Copolymer (COC): Channel depth: 100 µm; channel width: 200 µm; channel length: 1,879 mm; number of cycles: 41; lid thickness 125 µm.

COC is a solvent-resistant plastic that can handle aqueous solutions (including acids and bases) and polar organic solvents. It also possesses excellent optical properties, with high optical transmission down to approximately 300 nm.

If you’re unsure about the meander chip reactor’s suitability for your application, contact one of our experts to ensure that the flow photochemistry pack matches your specifications!

Frequently asked questions

How can we help in your experiment?

This pack is in beta testing phase. So, although the instruments are not fully industrialized, we can provide extensive support as part of our beta testing program. Get in touch to see if you are eligible.

Can a pack be customized based on my specific application?

Yes! Our experts will establish which instruments are best suited for your application, such as the type of flow sensor or the number of flow controller channels you need to perform your experiment. Contact us using the “talk to our experts” green button above.

Can I buy individual instruments?

Our instruments are in beta testing phase and can be tested as a pack or individually, so get in contact with our team to know how our beta testing program works.