Our microfluidic skills: Microfabrication

Author

Camila Betterelli Giuliano, PhD

Publication Date

February 27, 2025

Keywords

Microfabrication

Thermoplastics

3D printing

Chip prototyping

Biocompatible printing

PDMS

customized flow cells

biocompatible printer

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

When people think about microfluidics, what comes to mind is usually the microfluidic chip. It makes sense because the magic happens inside the chip.

At the MIC, our main focus is on the instruments that go around the chip, i.e., the pumps, valves, sensors, etc. But none of this would make sense without the microfluidic chip. Thus, we cannot overlook the challenges researchers face when microfabricating their microfluidic devices.

PDMS microfabrication has democratised the access to microfluidics in many labs around the world, but, as the field advances, its limitations become more apparent. Thermoplastics came forth as a valuable substitute but their microfabrication is either too expensive or too difficult.

BioProS, easy chip prototyping with thermoplastics

As part of the project BioProS, the MIC aims to address precisely these limitations by creating a process of thermoplastic chip microfabrication analogous to the one in PDMS (GA no. 101070120).

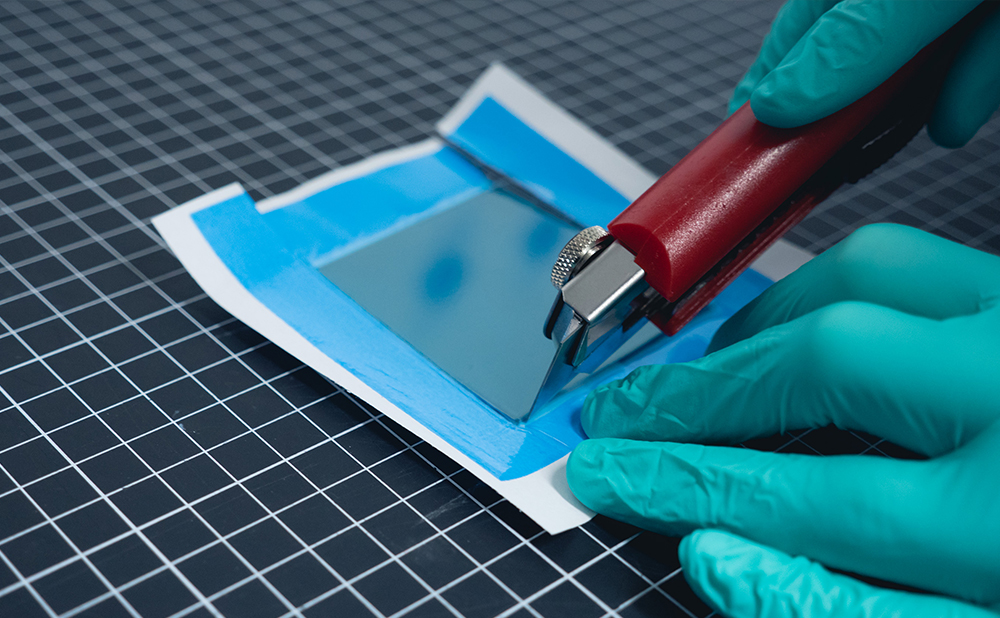

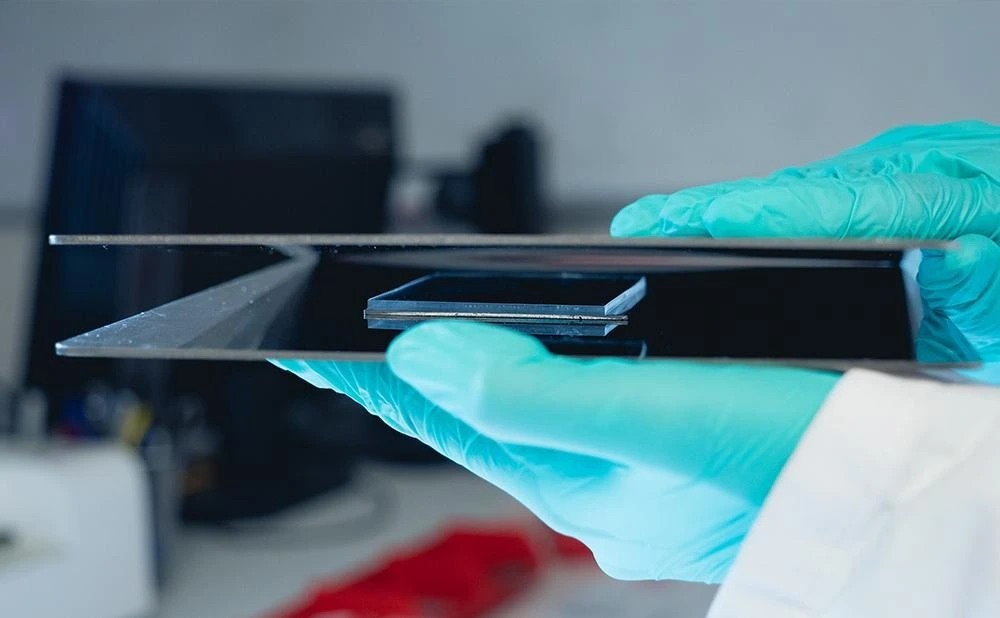

We used our expertise in fabricating PDMS chips without the need for a cleanroom and translated it to PMMA. The result is an effective protocol for fast and easy thermoplastic chip prototyping.

If you want to know more about the project or about the protocol, just follow the links!

Examples of PMMA chips

3D printing of customized flow cells

Different applications have different needs and, in some special cases, we 3D print custom-made flow cells to fulfill the needs of our projects. We have several printing methods in-house, including a biocompatible printer and resin.

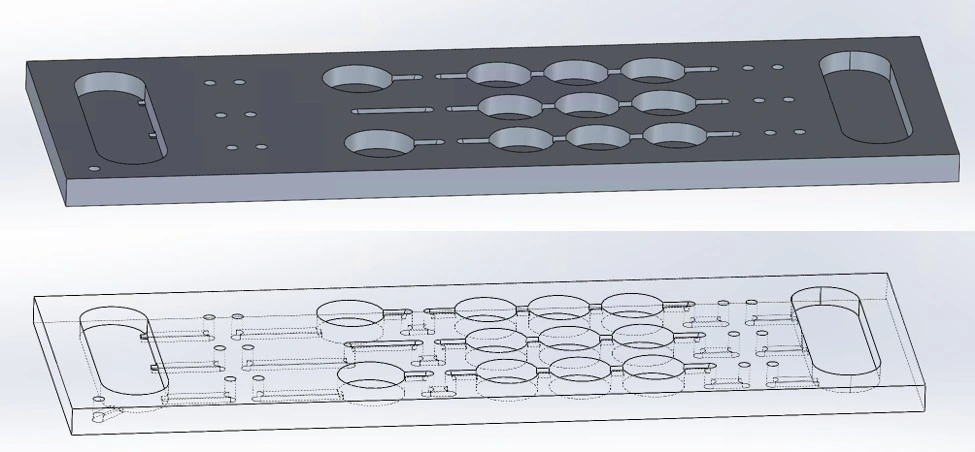

For example, for the project Panbiora, we designed and 3D-printed a microfluidics chip to adapt AMES tests, widely used genotoxicity tests, to microfluidics (GA no. 760921).

The test performed on our designed chip achieved a decrease by half of the testing time and required significantly less material and space.

If you want more info, the results are published here:

Varvara Gribova, Jesus Manuel Antunez Dominguez, Alan Morin, Julia Sepulveda Diaz, Philippe Lavalle, et al.. A miniaturized genotoxicity evaluation system for fast biomaterial-related risk assessment. Analytical Methods, 2023, 15 (12), pp.1584-1593.

https://hal.science/hal-04054693v1/file/islandora_161296.pdf

Want us as partners in your project for 2026-2027 call?

Curious what's next? Sign up for our Newsletter

FAQ – Microfabrication

Which materials are used to micro-fabricate?

- PDMS: simple and straightforward to prove.

- Thermoplastics (PMMA, COC/COP, PS, etc.): More robust, chemical-resistant, and scalable.

- Glass and silicon: When you want the toughest chemical, high temperature, or the very smallest features.

The selection of the material is always dependent on the requirements of use, optical clarity, gas permeability, chemical resistance, solvent compatibility, price, and so on.

What fabrication processes are on the menu?

PDMS photolithography and soft lithography are used to make PDMS channels. CNC micromilling and laser ablation are used for rapid thermoplastic chips. Hot embossing and solvent- or thermal-bonding are used for clean-channel replication. Wet/dry etching for glass/silicon when you need sub-100 µm accuracy and robust surfaces. Thin-film surface treatments, plasma activation, and selective coating to control wettability or biomolecule attachment.

Are you easy with thermoplastic chips?

So what about microfluidics 3D printing?

Another application of 3D printing (with biocompatible resins) is to print our own flow modules or chip holders where special layouts are required. These print works can be used to supplement, and even substitute for, portions of traditional chips.

What about surface chemistry and biocompatibility?

We can make channels hydrophilic/hydrophobic, anti-fouling, PEG-like-grafted, or prepare surfaces to which the antibody/ECM can bind. In cell work, we monitor extractables and use bonds and solvents with a proven track record of biocompatibility. In case of assay sensitivity, we will advise on upfront validation procedures (contact angle, burst tests, cytotoxicity).

What are the reasons for abandoning PDMS in favor of thermoplastics?

PDMS is excellent for preliminary tests; however, it has limitations (e.g., absorption of specific molecules and chemical incompatibility). Many real-life applications of thermoplastics have superior mechanical and chemical properties.

Which information does the company need to provide to receive a quote or a quick feasibility check?

A sketch or CAD (and rough enough), anticipated flow rates/pressures, fluids/solvents, temperature gradient, assay limitations (cells, enzymes, organic solvents), optical requirements, and desired batch size. In case you have already conducted benchtop tests, provide the facts and pain points- you will have a more precise proposal.

What is the role of MIC in a Horizon Europe consortium?

We handle engineering and system validation, while academic partners can focus on their scientific work.

Another factor that reviewers like is the presence of a small/ medium enterprise (SME) with practical experience within a project.

Actually, we usually increase proposal success rates twice, since we directly consider risk and manufacturability, the major evaluation factors.

What are the services that MIC can offer to a consortium?

We will work on the technical, innovation, and impact parts of the proposal, recommend partners when needed, and create microfluidic technologies. We also endorse those activities associated with market potential and influence.