Cell Culture Pump with Gas Control

Keep the pH and oxygen of your media constant outside the incubator

Gas control for incubator-free setup

Control the media gas mix for dynamic cell cultures outside the incubator

Stable long-term flow

Stable flow in the physiological profiles of your choice

Versatile

Hook your pre-mixed gas bottle or standard compressed air

Need a microfluidic SME partner for your Horizon Europe project?

Perfusion outside the CO2 incubator

Keep the gas concentration of your media constant (5% CO2, for example) in your perfusion experiments by pressurizing the media reservoir with the correct gas mix. The cell culture pump does not exchange gas with the atmosphere as most pressure-driven controllers do during regulation.

Therefore, the intended gas mix arrives at the reservoir without alteration and prevents the gas in the media from diffusing out of the liquid into the atmospheric air, changing its concentration. The constant flow of media ensures that the correct composition always reaches the cells.

The flow sensor maintains the correct flow rate throughout the perfusion in a feedback loop with the cell culture pump. The stage-top incubator keeps the temperature stable for long periods, allowing for high-quality live cell imaging experiments or more portable and convenient bench-top handling.

This pack contains:

Flow sensor (Galileo, MIC)

Software (Galileo user interface)

Stage top incubator

Cell culture pump

Fittings, tubings, luers

Reservoirs

Microfluidic chip (application-dependent; suggestion Microfluidic chipshop fluidic 480)

User guides for instruments

This instrument can also be adapted to our automated cell culture platform.

For applications requiring fluid injection to test the effects of drugs, for example, a rotary valve or a check valve recirculation bridge can be added to the setup. Check out our automated recirculation system and this application note that explains how to assemble the recirculation bridge.

Cell culture pump technical specifications

The cell culture pump can come with 1 to 4 channels. Each channel connects to a flow sensor with a feedback-loop between pressure and flow rate. Each channel has the following specifications (tested with a set pressure value of 2 bar):

| Characteristics | Specifications |

|---|---|

| Accuracy | +/- 2.5 mbar |

| Air consumption | few ml/min |

| Response time | 140 ms |

| Settling time | 2750 ms |

| Overshoot | 0.12 mbar |

If you want to know more, do not hesitate to contact our experts!

What comes inside the box?

When you order the pack, you can expect to receive the pressure regulator with the desired number of channels, the reservoirs, the software and the cable to connect to the computer and to the power supply, as seen below (the laptop is only illustrative).

Flow sensors are bought separately.

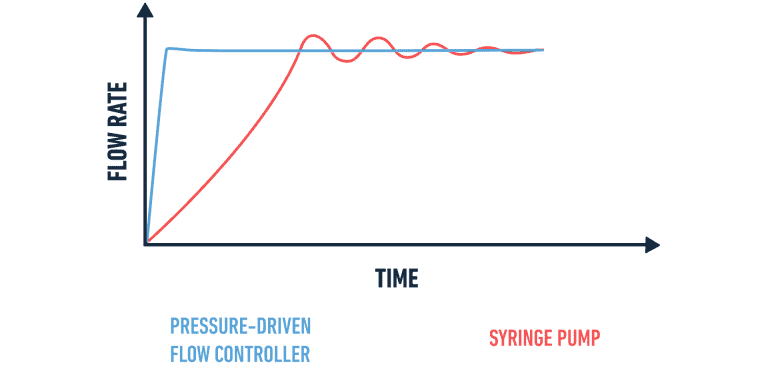

Why switch to pressure-driven flow control?

Pressure-driven flow control, such as the cell culture pump, provides better long-term stability than other types of flow generators. It also gives the possibility of choosing the best flow profile for your application: you can decide to have a pulsatile flow, stop-go, intermittent, stable, and continuous to more accurately replicate the ideal conditions of your experiment while peristaltic and syringe pumps are limited to pulsatile flows which are inherent to their mechanical nature.

Customize your pack

Our instruments can be added to different setups depending on your specific needs. In this light, our microfluidic specialists will advise you on the best instruments and accessories depending on your needs and will accompany you during the system’s setup.

Frequently asked questions

Which gases can the cell culture pump use?

The cell culture pump can use any non-corrosive gas mixture.

Can the cell culture pump be placed inside the CO2 incubator?

It was designed to be kept outside the CO2 incubator.

Does the cell culture pump keep the gas sterile?

To guarantee the sterility of the used gases, we advise adding a small disposable filter at the gas inlet of the reservoir.