PVA MICROSPHERES FORMATION PACK

Form microspheres with different PVA polymer solutions

High-speed control of flow rates for an increased generation frequency

Get more precise control with real-time monitoring and feedback

Easy and direct scaling up of the process from uL to L scale

PVA formation pack

We created an all-in-one platform to address a fundamental application directly for many researchers and R&D departments.

The main objective of this pack is to create monodisperse Polyvinyl Alcohol (PVA) microspheres by combining the flow control technology with commercially available or custom-made microfluidic chips in a precise and easy way.

Thanks to this synergy, the PVA microsphere formation pack will unlock the generation microspheres with the required properties, size, and distribution. Hence, it will be the perfect choice for complex high-end applications, such as medicine, tissue engineering, drug delivery, etc.

Why use microfluidics for microsphere formation?

Accurate control of flow and pressure is one of the most important components in the production of PVA, because it allows for the optimal adjustment of bead size and reproducible particle monodisperisity.

Currently, there are several techniques for the formation of PVA microspheres; however, these traditional methods do not allow adequate control of these variables hence resulting in poor dimension control.

Microfluidics, on the other hand, offers precise control over the generation and manipulation of micro beads or particles. One of the most important advantages is the precise control over the particle size, reproducibility, scalability and the reduction of waste.

Through the use of our pressure-driven flow control system it is possible to automatically and easily tune the PVA microspheres formation process. In fact the flow rates and fluid pressure in the microchannels are automatically monitored and adjusted through the combination of Elveflow’s best-selling flow sensor and OB1 flow controller.

Thanks to the performance of this set of equipment, you will be able to directly and reliably control the characteristics of your microspheres.

Importance

- PVA-based microspheres show good biocompatibility, low cost, and good chemical stability.

- Perfect for a wide range of PVA polymer solutions to create microspheres with a variety of sizes and properties.

- High reproducibility and precise control: high precision and accuracy in production of PVA microspheres with low levels of wastage.

- Microfluidic devices can be easily scaled up for mass production (industrial-scale production).

- Elveflow OB1 can produce PVA microspheres faster than traditional methods.

PVA formation pack setup

Do you want to customize your microspheres? With our pack you will be able to try all the different configurations and obtain the microspheres you want.

If you decide to further customize the formation of your PVA microspheres you can start from the design of your microfluidic chip.

Some of the most important considerations to make are: The amount of input substances you will use and the shape of the junction in which your substances will interact to form the microspheres.

For more information on how to design your chip or microfluidic system see the Specifications tab below.

Once you have decided which parameters are most important for your research you can move on to using your microfluidic device and adapting it to our pack.

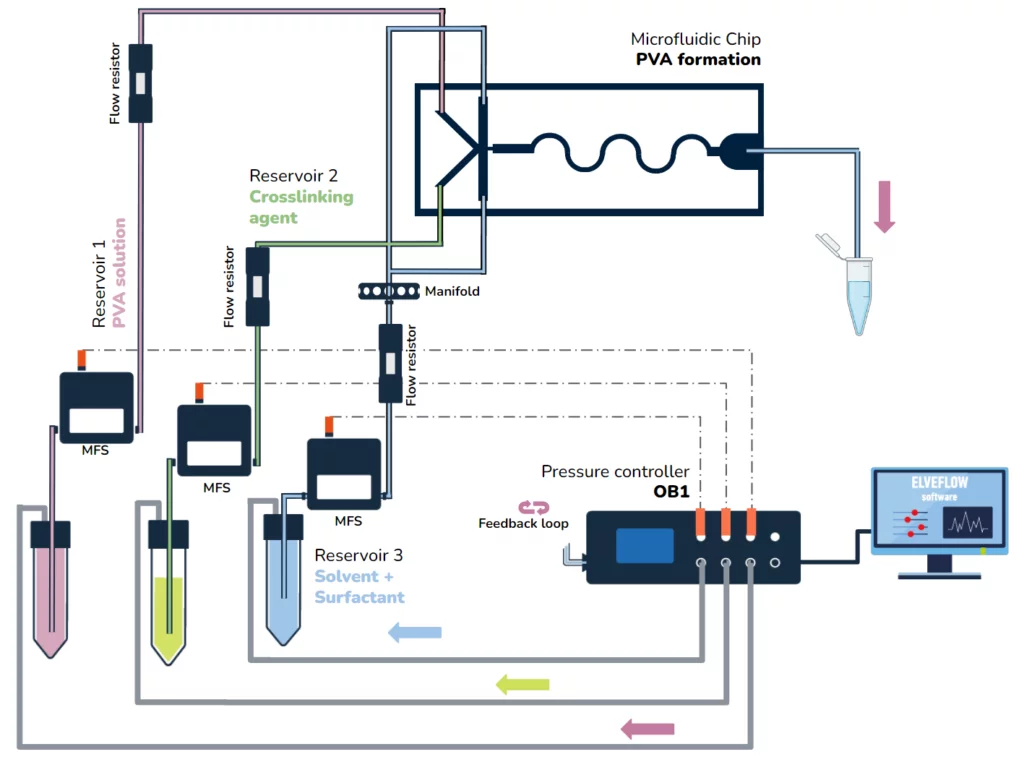

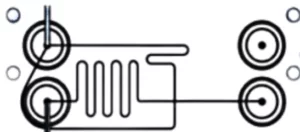

Model N° 1

The solutions necessary for the operation of this pack would be:

1. Polyvinyl alcohol (PVA) solution (dispersed phase).

2. W2 solution (dispersed phase): mixture of glutaraldehyde (GA) and acide chlorhydrique (HCl) solution (crosslinking agent).

3. Liquid paraffin containing 5 wt.% EM90 as the surfactant (continuous phase, inlet O) (solvent and surfactant).

On the chip, the generation of the microspheres will start (by droplet generation) where PVA/GA hybrid aqueous droplets will be formed at the junction of the microchannel. Subsequently, the PVA and GA will be mixed in the serpentine-shaped channel which will increase the mixing efficiency. Then, this mixture will be gelated into microspheres in the pre-curing zone and transported into a polyethylene tube for further deep curing.

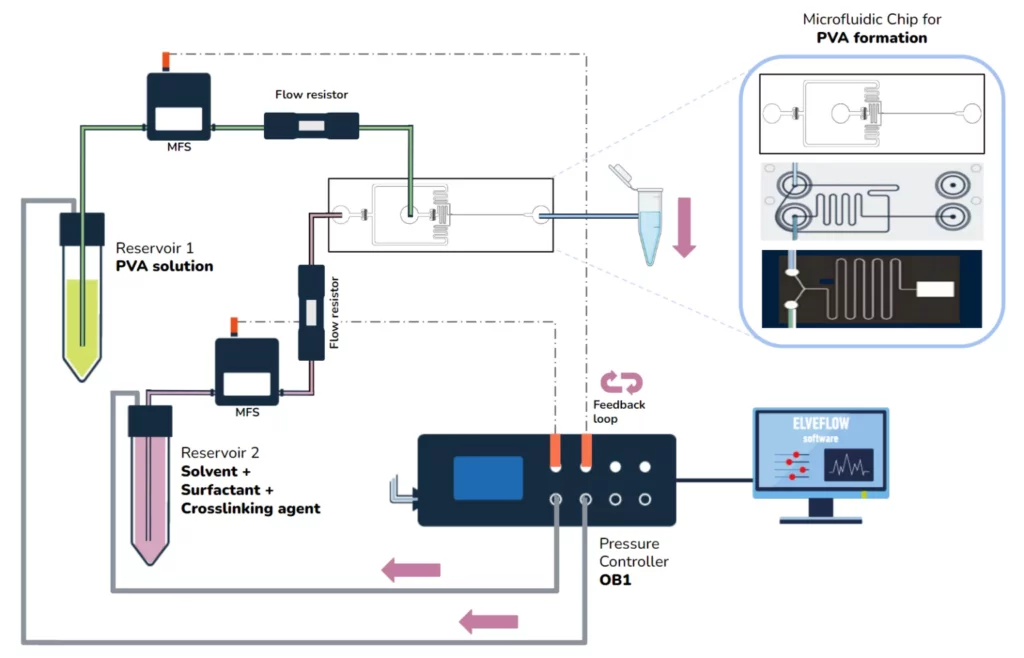

Model N° 2, 3 and 4

The solutions necessary for the operation of these packs would be:

1. Polyvinyl alcohol (PVA) solution (dispersed phase).

2. Mixture of GA, HCl, liquid paraffin and EM90 as the surfactant (solvent, surfactant and crosslinking agent).

A typical pack contains:

- OB1 pressure controller (Elveflow) with 2 or 3 control channels (one for each solution): The OB1 Flow controller provides a fully automated precise control over the flow rate and pressure of fluids. You can create PVA microspheres with a uniform size and shape.

- Flow rate sensors (Elveflow) (one for each channel): MFS (water-based solutions / 5% accuracy) or BFS (calibration free / 0.2% accuracy).

- Sets of flow resistors (for stable and accurate flow control).

- One Microchip customized or purchased from ChipShop.

- Elveflow SDK (C++ / Matlab / Labview / Python) or serial communication protocol.

- All necessary containers and tubes.

The system:

- The OB1 pressure controller is a microfluidic pump that can be used to precisely control the flow of fluids through microchannels. This pump will need to be connected to the PVA solution and to the oil phase using tubing and fitting.

- The three different solutions will be accurately pumped to the PDMS chip with the help of flow rate sensors. The stability and the speed of the reaction directly depend on the flow rates of each fluid and their ratios in the microfluidic channel.

The flow is generated by the OB1 flow controller and the flow rates are measured and regulated thanks to flow rate sensors (MFS or BFS series) permitting a very high accuracy and stable flow control.

The combination of these instruments is the fastest and most precise microfluidic flow control available on the market which guaranties the best possible monodispersity and reproducibility. Furthermore, the lipid nanoparticle synthesis process can be automated thanks to the software controlling Elveflow instruments.

The software:

Elveflow software will allow you to program the pack pump in a user-friendly way. This software will allow the pump to generate the desired flow rates for the PVA solution and the other substances.

In this case, this software will allow you to adjust the flow rates to control the droplet size and production rate of the microspheres. Also, real-time feedback on the flow rate and pressure of fluids will be useful to optimize the production process and troubleshoot any issues that arise.

PVA formation pack applications

Some of the most important applications for the formation of PVA microspheres are as follows:

- Imaging: The PVA microspheres can be used as contrast agents for imaging applications because allow to provide a high signal-to-noise ratio. Also, PVA microspheres can be used for medical or biological imaging applications because of their high biocompatibility.

- Tissue engineering: PVA microspheres can give an structural support as scaffold for the production of tissue and promote the proliferation and regeneration of cells.

- Gene therapy: PVA microspheres can be used for gene delivery to cells in the body because the genetic information can be encapsulated and delivered to a specific target.

- Controlled drug release: PVA microspheres can carry different types of drugs due to their porous structure. In turn, it is perfect for drug delivery application because it allows sustained release of drugs over time with specific targets.

- Cosmetics: PVA microspheres can be used in skin care products. Some of the most important properties for this industry are their exfoliating properties.

- Diagnostics: PVA microspheres can be loaded with diagnostic molecules to find biomarkers in the body. The high loading capacity of these microspheres allows them to store genetic information such as DNA probes and antibodies for disease detection.

The pack forming system will allow you to produce PVA microspheres with precise size and shape control. In addition, our pack will help you to obtain a high-performance and scalable production that will allow you to save time and costs for any industry and application.

With our all-in-one configuration, produce the customized PVA microspheres you need for your research.

Image Credit: Hormone release from a kidney cell, STORM and TIRFM. Alison Dun, ESRIC (Edinburgh Super-Resolution Imaging Consortium).

Licence: Attribution 4.0 International (CC BY 4.0)

PVA formation pack design

Chip design

The microfluidic chip design will allow you to have better control over each of the features of your PVA microspheres. For example, throughout the PVA formation process, the emulsion can be formed using a coaxial flow or a T-junction approach. In addition, the emulsion can be generated with 2 or 3 input solutions.

In general, you have to take into account the addition of a model that allows you to generate proper mixing and formation of the microspheres according to your needs. The choice of microfluidic design depends on several factors, such as the desired size and shape of the microspheres, the concentration and viscosity of the PVA solution, and the type and number of inlets available.

Three different chip designs can be provided with this pack, depending on your requirements:

CHIPSHOP

Droplet generator (Chip glass)

*This chip FLUIDIC 440 can be purchased at MICROFLUIDICS CHIPSHOP

Customized chip

Chip with 2 inlet substances

Chip with 3 inlet substances

It is important to know

If you decide to start with the amount of inlet substances your microfluidic device will have, it is important to consider the nature of the type of substance you need. In principle, according to the PVA microspheres fabrication protocol you need some indispensable chemicals. These are as follows:

|

Polyvinyl alcohol (PVA)

|

Polymer mainly used in the formation of microspheres

|

|

Must be dissolved in a solvent to undergo emulsification and bind to a crosslinking agent

|

|

|

Solvent

|

Immiscible solvent that can be nonpolar oil to create an emulsion when in contact with PVA

|

|

Crosslinking agent

|

A chemical agent that will be added to the PVA solution to initiate the crosslinking process

|

|

Surfactant

|

Will stabilize the emulsion and favor the prevention of droplets coalescence

|

How many input substances should be used?

There are different ways of combining the substances in order to achieve a customized formation of the PVA microspheres. Each of these has its advantages and disadvantages that will allow you to discern which alternative to use in order to have the PVA formation pack that fits your requirements.

Likewise, choosing how many input substances you will need for the formation of your PVA microspheres will help you to choose the channel design of the microfluidic chip.

For example, one of the main variations is whether the crosslinking agent is added before or after the emulsion enters the microfluidic chip. Below are some of the advantages and disadvantages of using 2 or 3 inlet substances depending on when the crosslinking agent is added.

With 3 inlet substances

With 2 inlet substances

In this situation, the crosslinking agent is added to the solution after the emulsion enters the microfluidic device. That is, in this case we would have 3 input substances where the first is the PVA solution, the second is the solvent mixed with the surfactant and the third is the crosslinking agent.

In this situation, the crosslinking agent is added to the solution before the emulsion enters the microfluidic device. That is, in this case we would have 2 input substances where the first is the PVA solution, the second is the solvent mixed with the surfactant and the crosslinking agent.

Advantages:

- Greater control over production: better regulation of emulsion stability and crosslinking speed

- Greater flexibility in optimizing reagent concentrations

- Uniformity of microspheres (size and shape) due to less likely formation of aggregates

Advantages:

- Simplicity that facilitates the manufacturing and operation of the device

- Less complexity of the production process (less time and resources)

- Lower cost

Disadvantages:

- Increased complexity: makes device fabrication, production and operation more difficult

- Higher cost

Disadvantages:

- Less control over production

- Less uniformity in size and shape of microspheres due to formation of aggregates

- Difficulty in optimizing reagent concentrations

What type of input design should you use?

After deciding how many input substances you will use in your microfluidic system you must consider what type of geometry you will use for the formation of the PVA microspheres.

Normally two types are used: T-junction geometry with two inlets and Coaxial flow configuration with two or three inlets. This junction will allow you to determine which parameter you want to optimize in the formation of your microspheres. That is, if you want to obtain microspheres with a wide range of sizes, the use of the T-junction geometry would be recommended. However, if the objective is to better control the uniformity of size and shape you should employ the coaxial flow configuration.

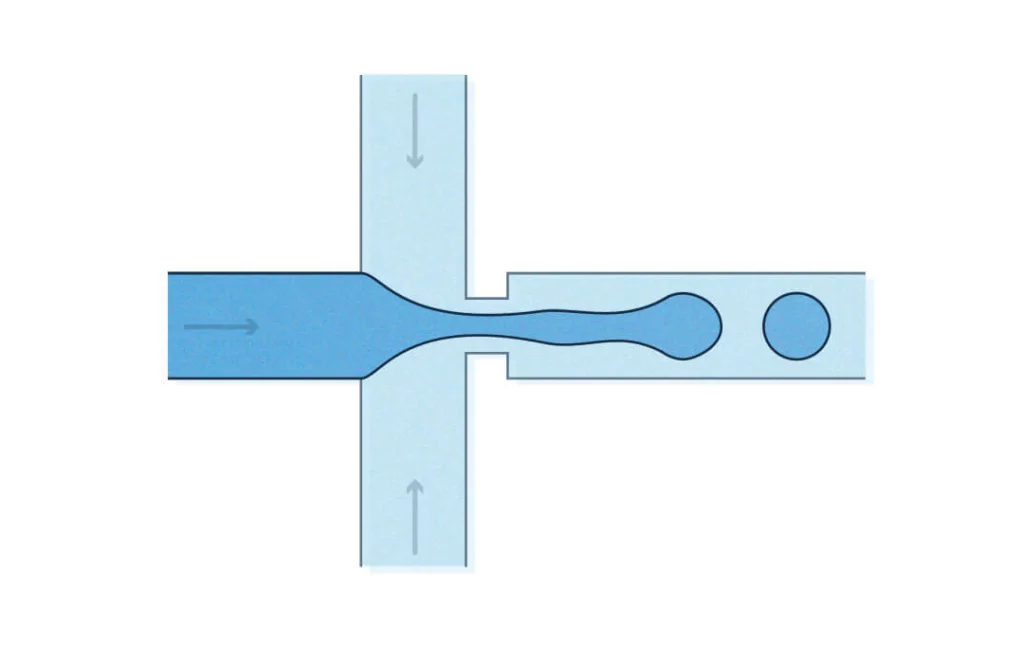

Coaxial flow configuration with 2-3 inlets

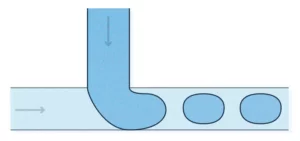

T-junction geometry with 2 inlets

The coaxial flow configuration uses a capillary tube or a concentric channel geometry with three inlets. The PVA solution is delivered through the innermost inlet, while a non-solvent or a coagulant is delivered through the outermost inlet.

The surfactant solution is delivered through the middle inlet to help stabilize the droplets and prevent coalescence.

The flow-focusing configuration (T-junction geometry with two inlets) delivers the PVA solution in one inlet and the other inlet delivers a cross-flowing stream (non-solvent or a coagulant), which causes the PVA to precipitate and form microspheres.

The size of the microspheres can be controlled by adjusting the flow rates of the PVA and coagulant streams.

Advantages:

- Greater control over the size and shape of the microspheres: allows adjusting the ratio between internal and external solution flow

- Increased production capacity

- Emulsion stability and prevention of microsphere coalescence

Advantages:

- Greater control over production: better regulation of emulsion speed and stability

- Reduced complexity: Facilitates manufacturing and operation

- Greater uniformity of microspheres (size and shape)

Disadvantages:

- Increased complexity

- Increased sensitivity to operating conditions such as flow rate and solution properties which may require further optimization of the process

- Increased difficulty in achieving production uniformity

Disadvantages:

- Reduced ability to add surfactants or stabilizers

- Increased susceptibility to clogging due to aggregate buildup at the point of intersection, which can affect uniformity and production efficiency

Finally, once you have decided which design features you want to have in your microfluidic system, you just need to adapt it with our pack to start producing your own PVA microspheres!

Customize your pack

Our products and packs are fully customizable so that they will be perfectly adapted to your needs. Our specialists and researchers can help you choose the best instruments and accessories. In addition, they will accompany you during the setup of the microfluidic platform until you get the experimental results you need.

Please contact our experts if you have any questions about this pack and how it can fit your specifications.

– Check our other Packs for various applications –