Oligosaccharide Synthesis

A microfluidic toolkit for precise and automated carbohydrate assembly

Precision flow

Accurate reagent delivery for synthesis

Automated assembly

Simplified chain assembly

Built-in flow monitoring

Real-time flow control with our flow sensor

Need a microfluidic SME partner for your Horizon Europe project?

Optimizing oligosaccharide synthesis with microfluidic flow control

Oligosaccharide synthesis plays a critical role in glycoscience, but researchers often face challenges using traditional batch and syringe-based methods. These methods frequently cause inconsistencies, waste valuable reagents, and offer poor reproducibility, especially during multi-step glycosylation workflows. To reliably assemble complex glycans, you need precise control over reagents, flow, and timing [1].

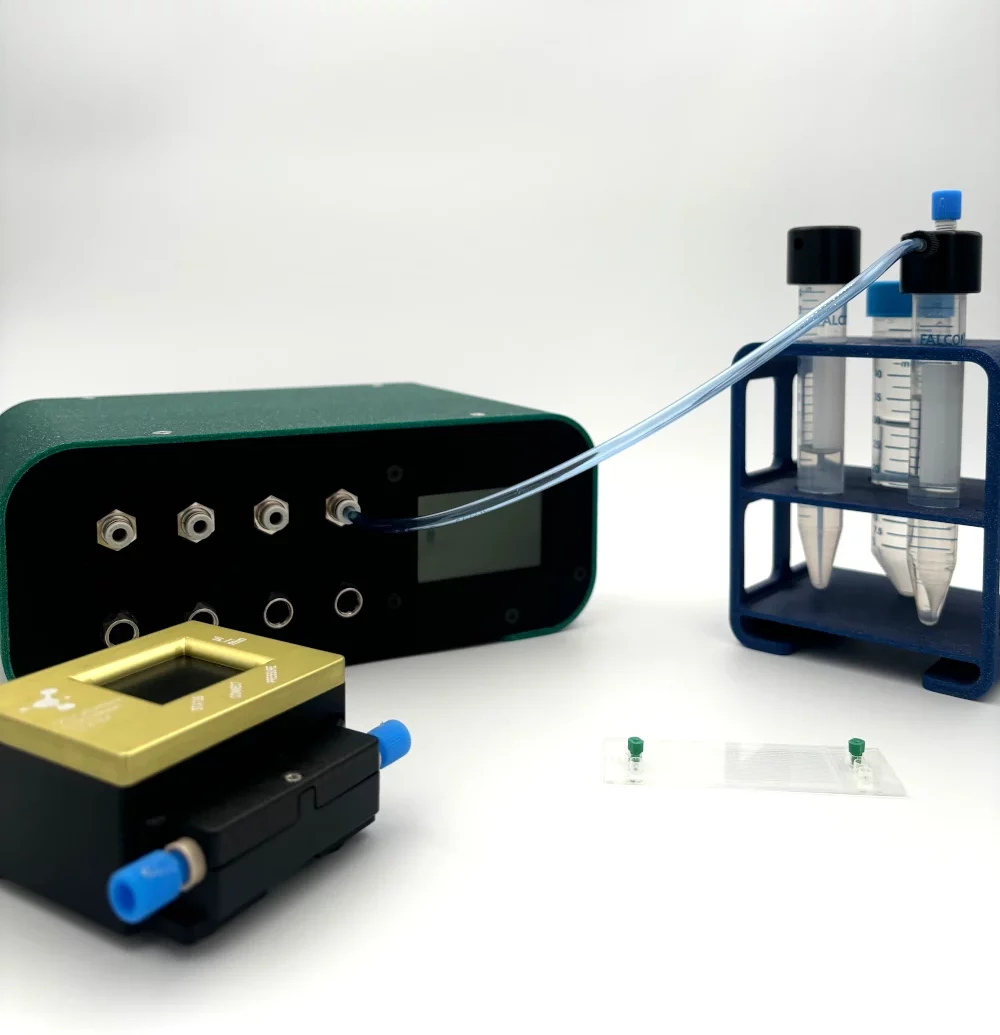

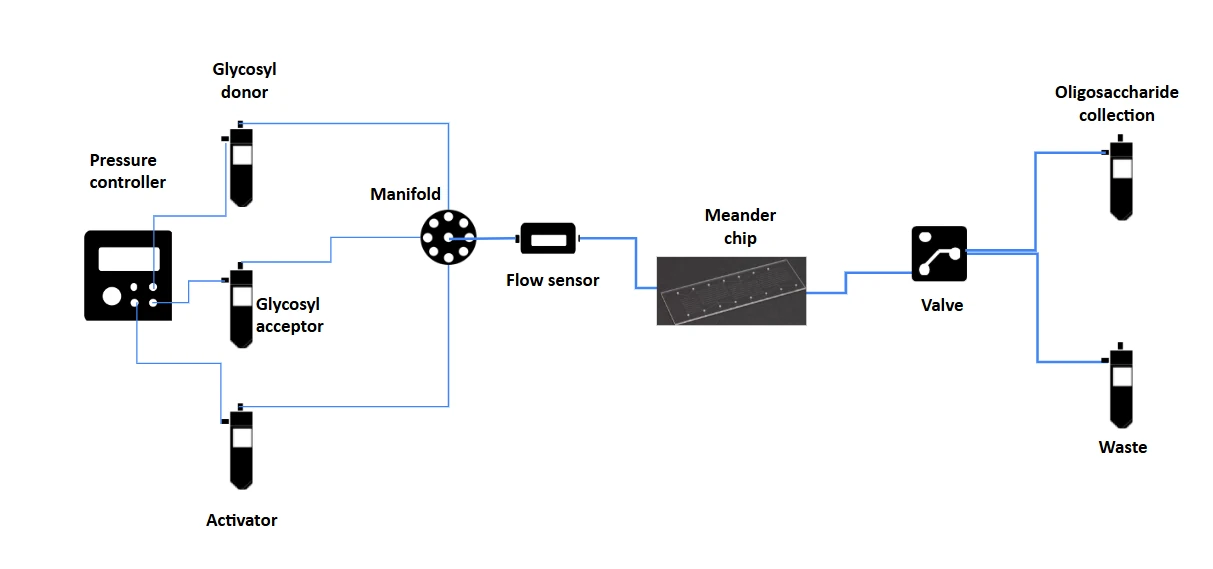

Our modular microfluidic system, centered around a pressure-driven pump, is engineered to solve these problems through stable flow delivery, programmable pressure control, and on-chip mixing using a meander microfluidic chip. Moreover, to ensure accuracy at every step, the system integrates a microfluidic flow sensor, providing real-time feedback with continuous flow monitoring, thus enabling fine-tuned control of flow rates [2].

Unlike conventional systems that risk pulsation or mixing atmospheric gas with reagent streams, this setup maintains true input gas and liquid composition, preserving the integrity of your reactions. Consequently, the result is a streamlined platform that supports efficient, reproducible oligosaccharide assembly which is ideal for both chemical and chemoenzymatic workflows [3].

Setup

Pressure pump for microfluidics

Microfluidic flow rate sensor

Meander microfluidic chip glass (eg. Microfluidic ChipShop)

Reservoirs, tubing, connectors

Microscope (optional)

References

Image:

Test tubes descending shades of blue by Minhaa, Wikimedia commons

Text:

Seeberger, P. H., & Werz, D. B. (2007). Automated solid-phase synthesis of oligosaccharides.

Södergren, S., Svensson, K., & Hjort, K. (2021). Microfluidic active pressure and flow stabiliser.

Zhang, Y., et al. (2023). Microfluidics-Based Ionic Catch and Release Oligosaccharide Synthesis.

Oligosaccharide synthesis applications

- Oligosaccharide synthesis and optimization

- continuous-flow glycosylation reactions

- Chemoenzymatic sugar extension

- Automated carbohydrate assembly workflows

- Glycan screening and microarray preparation

Microfluidic flow rate sensor technical specifications

Flow rate ranges: For example, flow rate ranges with <5% accuracy:

0.5 – 60 µL/min

2 – 150 µL/min

40 – 1200 µL/min

0.5 – 10 mL/min

Note that the range can be customized depending on working fluid properties (viscosity, etc.)

Calibrated liquids: aqueous media (others are possible upon request)

Wetted materials: PEEK, steel, fluorosilicone, perfluoropolyether resin

Internal volume: approx. 40 µL (variable depending on the used configuration range)

Operation pressure: up to 3 bar gauge pressure

Maximum pressure rating: up to 6 bar gauge pressure

Software operability: standalone GUI for data visualization and logging; optional Python API

Please note that this is a beta version of this technology, so exact specifications are subject to change.

Microfluidic pressure pump technical specifications

The microfluidic pressure pump can come with 1 to 4 channels. Each channel connects to a flow sensor with a feedback-loop between pressure and flow rate. Each channel has the following specifications (tested with a set pressure value of 2 bar):

| Pressure control | |

|---|---|

| Accuracy | +/- 2.5 mbar |

| Air consumption | few ml/min |

| Response time | 140 ms |

| Settling time | 2750 ms |

| Overshoot | 0.12 mbar |

Customize your pack

Our instruments are compatible with standard commercialized chips from different brands.

Our instruments can be added to different setups depending on your specific needs. In this light, our microfluidic specialists will advise you on the best instruments and accessories depending on your needs and will accompany you during the system’s setup.

Frequently asked questions

Can the pressure pump be integrated with existing lab equipment?

Yes, the pump is designed for easy integration with microfluidic setups, chemical reactors, and gas mixing systems.

Can the flow sensor’s cartridges be reused?

Yes, depending on the experiment. The flow sensor cartridges can be reused if there’s no alert of clogging, or if you face no problems of cross-contamination in your experiment.

Do I need a microscope?

Not required, but useful for chip visualization or troubleshooting.

How can we help your experiment?

This pack is in beta testing phase. So, although the instruments are not fully industrialized, we can provide extensive support as part of our beta testing program. Get in touch to see if you are eligible.

Funding and Support

This project has received funding from the European Union’s Horizon research and innovation program under HORIZON-EIC-2023-PATHFINDEROPEN-01, grant agreement no. 101130747 (Bio-HhOST).

The development of the Galileo flow sensor has received funding from the European Union’s Horizon research and innovation program under HORIZON-EIC-2022-TRANSITION-01, grant agreement no. 101113098 (GALILEO).

Products & Associated Accessories

FAQ - Oligosaccharide synthesis

What are the problems that microfluidic technology solves in the synthesis of oligosaccharides?

The conventional oligosaccharide production methods of batch and syringe-based reactions have serious drawbacks, such as inconsistency of product quality, loss of useful and even costly reagents, and lack of reproducibility, especially in multi-step glycosylation processes. Such classical methods lack specific control over key factors such as reagent delivery, flow behavior, and reaction time, which are vital for ensuring reproducible assembly of complex glycan assemblies that are fundamental to glycoscience and pharmaceutical studies.

What is the benefit of the pressure-driven microfluidic system to oligosaccharide synthesis?

The modular microfluidic system has a pump designed to be pressure-driven, with the aim of delivering a stable flow, pressure control that is programmable, and efficient mixing on the chip using meander microfluidic channels. In contrast to traditional systems that risk pulses or mixing of atmospheric gases with reagent streams, this design will retain the true input gas and liquid compositions and preserve the integrity of the reaction. The microfluidic flow sensor is an integrated device that provides real-time feedback by continuously monitoring flow rates, allowing them to be fine-tuned as each step of the synthesis proceeds.

What are the main uses of this microfluidic oligosaccharide synthesis platform?

The platform is compatible with five key applications: the synthesis and optimization of oligosaccharides, continuous-flow glycosylation reactions, chemoenzymatic sugar extensions, automated carbohydrate assembly processes, and glycan screening using microarray-based methods. The system is compatible with both chemical and chemoenzymatic workflows and can be used in glycoscience research in diverse ways, including basic research, applied pharmaceutical development, and diagnostics.

What are the maximum and minimum flow rates of the microfluidic flow sensor?

The flow sensor has the option of customisable flow rates within a range below 5% accuracy, and it has 0.5 to 60 microliters per minute, 2 to 150 microliters per minute, 40 to 1200 microliters per minute, and 0.5 to 10 milliliters per minute. These ranges can also be further tailored to properties of the working fluid, such as viscosity, so researchers can tailor the system to the reagent’s needs. Calibration of the sensor is in aqueous media, and other liquids are available on request.

What are the materials in the construction of the flow sensor?

The flow sensor uses wet materials such as PEEK (polyether ether ketone), steel, fluorosilicone and perfluoropolyether resin that had been chosen due to their chemical resistance and their compatibility with different organic solvents and reagents commonly used in production of oligosaccharides. The sensor has an internal volume of about 40 microliters (configuration-dependent), supports pressures up to 3 bar gauge, and a maximum pressure of 6 bar gauge.

What are the technical characteristics of the microfluidic pressure pump?

The pressure pump is available in 1- to 4-channel configurations, with a flow sensor and feedback-loop control of pressure and flow rate. Each channel, when tested at a set pressure of 2 bar, has an accuracy of plus or minus 2.5 millibars, a minimum air consumption of a few milliliters per minute, a response time of 140 milliseconds, a settling time of 2750 milliseconds, and a low overshoot of just 0.12 millibars, which is stable and precise control.

Is it possible to have a flow sensor cartridge used in subsequent experiments?

Flow sensor cartridges can be reused, depending on the experimental conditions. Reuse should be used when there is no clogging alert and when cross-contamination is not significant in the given experiment. This reusability attribute is useful for lowering operating costs while maintaining measurement accuracy, and researchers are advised to test compatibility based on their reagents and the various protocols they plan to use during the synthesis process.

Does the pressure pump integrate with the available laboratory equipment?

Yes, the pump was designed specifically for easy interconnection with microfluidic systems, chemical reactors, and gas mixers commonly found in chemistry and biochemistry laboratories. The modularity enables researchers to integrate the system into the current workflow without requiring extensive reconfiguration. Microfluidic experts offer advice on selecting the highest-quality instruments and accessories based on the experiment’s specific requirements and help set up the system.