Droplet Generator Pack

Achieve high-precision droplet microfluidics

Precise flow control

Delivers unparalleled accuracy in fluid regulation

Reproducible and easy generation

Produce highly monodisperse droplets (CV<3%)

Versatile for multiple applications

Cell encapsulation, emulsions, droplet sorting, particle synthesis, etc.

Need a microfluidic SME partner for your Horizon Europe project?

Droplet generator pack

What is a droplet generator for microfluidics?

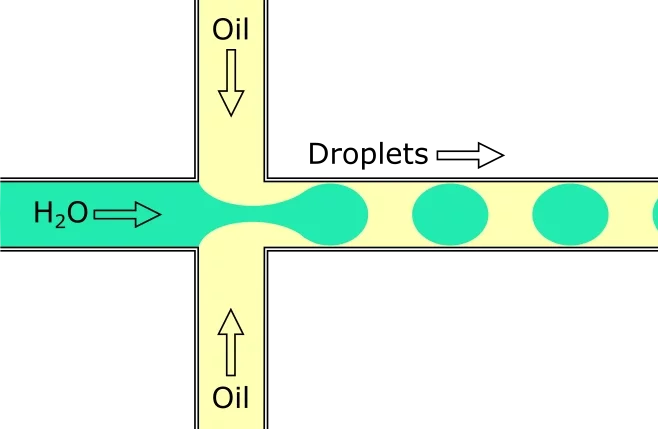

Droplet microfluidics is an advanced technique that enables the precise manipulation of liquid droplets within microchannels, providing a highly controlled environment for chemical and biological processes [1]. By leveraging a setup like a droplet generator pack, and enabling liquid handling for precise droplet formation, researchers can produce uniform and stable droplets by controlling the flow of immiscible phases, such as oil and water.

Moreover, this ability to generate monodisperse droplets with precision has transformed numerous research fields, allowing for enhanced reaction control, increased efficiency, and significant reductions in reagent consumption [2]. The integration of a droplet generator into experimental workflows ensures high-throughput and reproducible droplet formation, making it a critical tool for applications ranging from drug discovery to materials science [3].

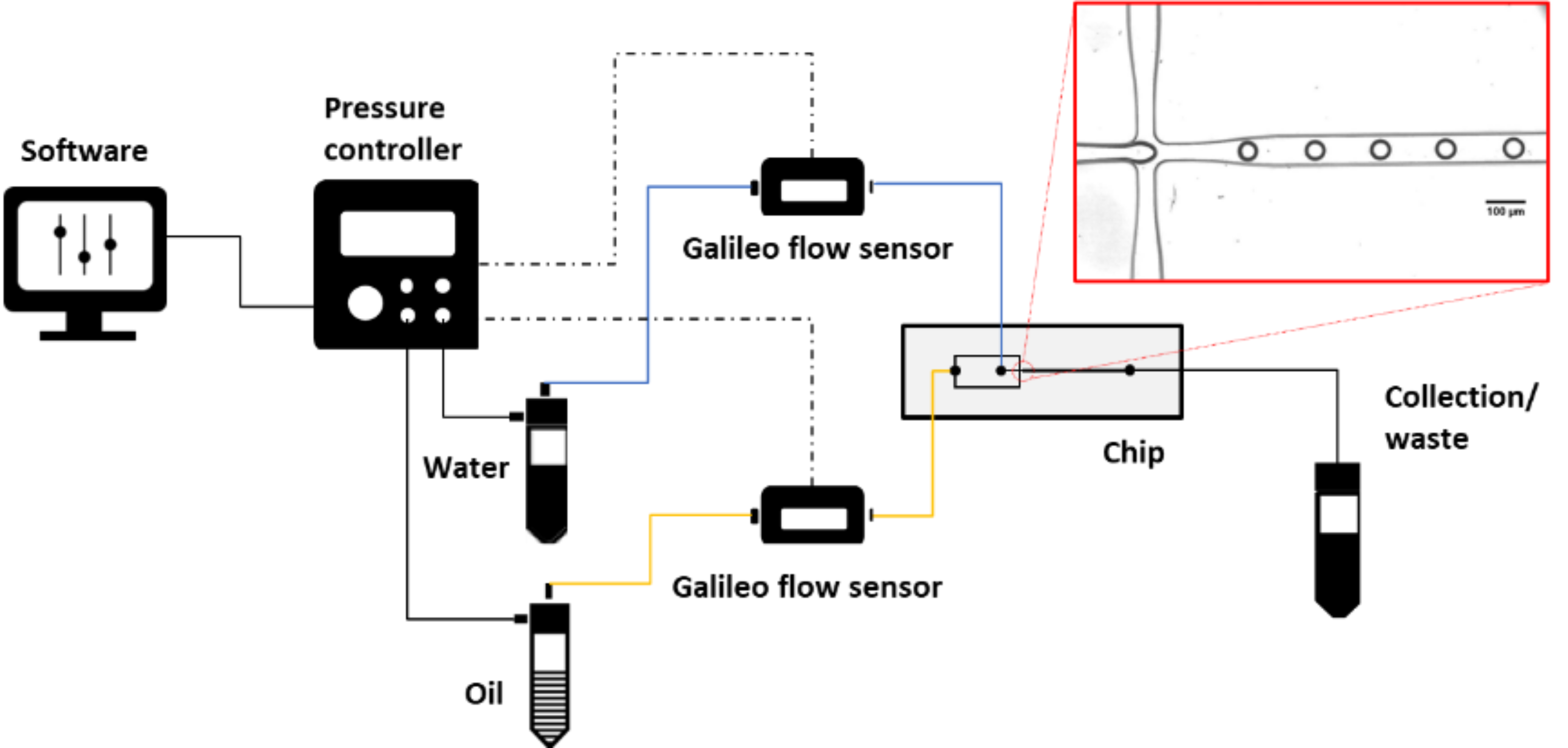

Setup

Flow sensor (Galileo, MIC)

Pressure controller

Your own Imaging system

Reservoirs

Tubings and fittings

Microfluidic chip

User guide

Software

Use-case application of viscous liquid flow rate measurement

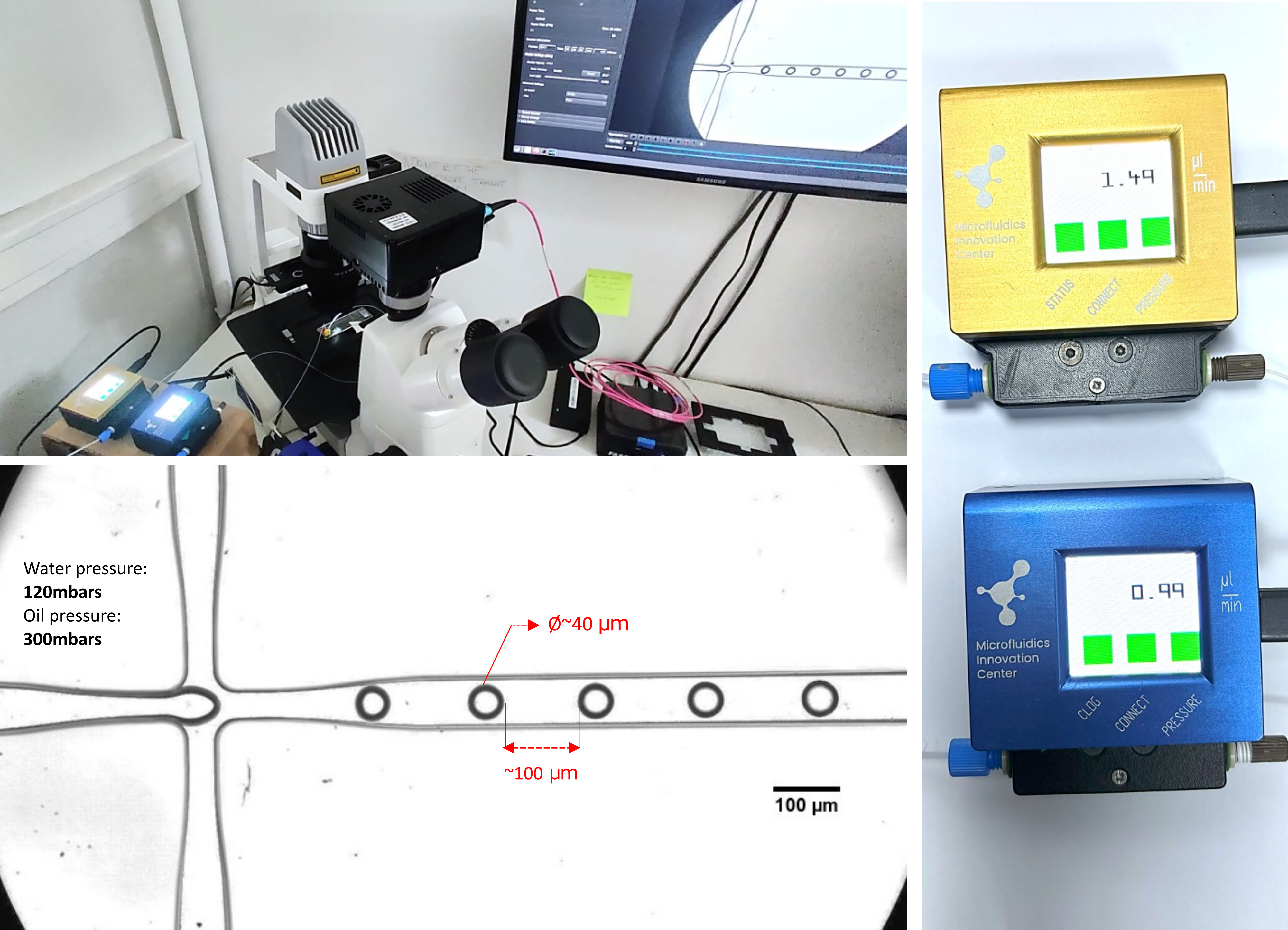

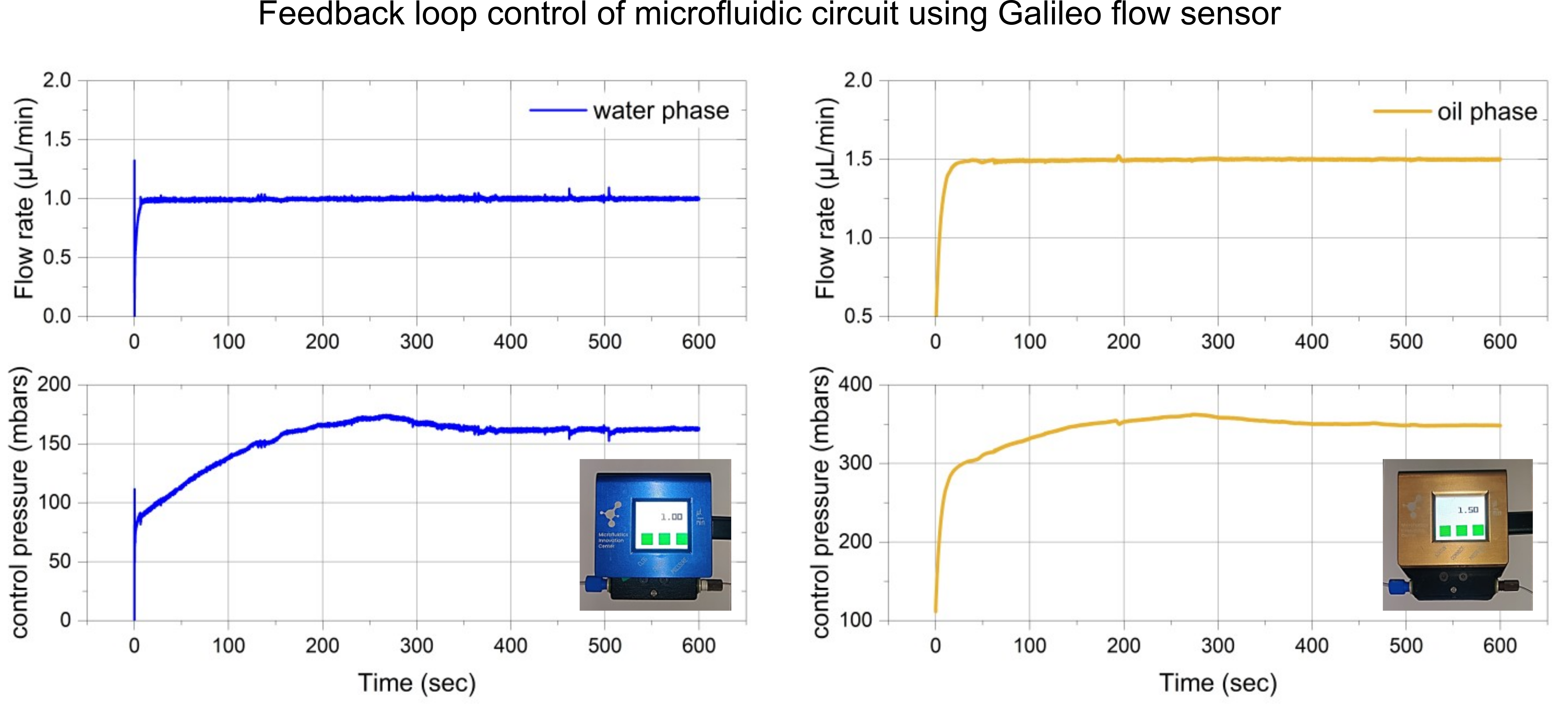

An application of viscous liquid flow rate measurement and/or control is shown for microfluidic droplet generation (Figure 3). In this setup, water-in-oil (W/O) droplets were generated using hexadecane as the continuous phase and water as the dispersed phase, within a cross-junction microfluidic channel.

References

1. Yadav, S. et al. (2022). Droplet microfluidics: fundamentals and its advanced applications.

2. Zhang, H. et al. (2015). Recent advances in applications of droplet microfluidics.

3. Ali, M. et al. (2023). Droplet microfluidic technologies for next-generation high-throughput screening.

Applications of droplet generator pack

The use of droplet generators extends far beyond simple droplet formation. In biomedical research, droplet generator systems allow for encapsulation of single cells, enabling precise genetic and proteomic analysis. This technology plays a crucial role in single-cell sequencing and personalized medicine, where controlled droplet formation ensures consistency across experiments [1].

With the ability to rapidly produce thousands of droplets per second, researchers can analyze vast sample sets with unparalleled efficiency, accelerating the development of new drugs and therapeutic compounds [2].

Beyond biological research, droplet generator technology is widely used in nanoparticle and microparticle synthesis, ensuring uniform size and composition [3]. In material science, the controlled production of emulsions, minocapsules, and structured materials has opened new possibilities for drug delivery systems, chemical reactions, and advanced coatings [3]. The ability to fine-tune droplet size and stability makes droplet generators invaluable in fields such as food science, environmental testing, and industrial formulation, where precision is essential [3].

The increasing adoption of droplet generators across various disciplines highlights their ability to improve experimental reproducibility, minimize waste, and enhance analytical accuracy [4]. As microfluidic technology continues to evolve, next-generation droplet generators will play an even greater role in automated laboratory workflows, scalable drug development, and industrial applications [4].

By integrating a high-precision droplet generator, researchers and industry professionals can achieve a new level of control, efficiency, and innovation in their work.

References

Yadav, S. et al. (2022). Droplet microfluidics: fundamentals and its advanced applications.

Ali, M. et al. (2023). Droplet microfluidic technologies for next-generation high-throughput screening.

Wang, J. et al. (2017). Droplet Microfluidics for the Production of Microparticles and Nanoparticles.

Robotic automation of droplet microfluidics (2022).

Perfusion pump technical specifications

| Pressure control | |

|---|---|

| Pressure range | -400 to 600 mbar |

| Pressure stability | 0.2 mbar |

| Air flow rate | 0.1 L/min at atmospheric pressure Possibility to work with higher air flow rates by reducing the pressure range |

| Flow control | |

| Microfluidic flow sensor | Monitoring and feedback loop flow control available |

| Flow rate | From 0.1 µL/min to 5 mL/min |

Flow sensor technical specifications

Flow rate ranges: For example, flow rate ranges with <5% accuracy:

- 0.5 – 60 µL/min

- 2 – 150 µL/min

- 40 – 1200 µL/min

- 0.5 – 10 mL/min

Note that the range can be customized depending on working fluid properties (viscosity, etc.)

Calibrated liquids: aqueous media (others are possible upon request)

Wetted materials: PEEK, steel, fluorosilicone, perfluoropolyether resin

Internal volume: approx. 40 µL (variable depending on the used configuration range)

Operation pressure: up to 3 bar gauge pressure

Maximum pressure rating: up to 6 bar gauge pressure

Software operability: standalone GUI for data visualization and logging; optional Python API

Please note that this is a beta version of this technology, so exact specifications are subject to change.

Frequently asked questions

Can I use other types of pumps to drive the fluid?

Yes, droplet generation is possible with a pressure source, syringe pumps and peristaltic pumps. Make sure that the pump delivers the right flow rate as this affects the droplet generation and its size.

How do I ensure my pump provides stable/right flow rates?

Use a pressure driven source for better stability and accuracy of flow. In case of syringe pumps or peristaltic pumps, use a flow sensor (like Galileo) in-line, to be sure the pump delivers the right flow rate.

I do not have droplets or they are inconsistent. What do I do?

Make sure the flow rates are right, the channel is flushed/cleaned before starting and you use the right surfactant concentration.

How can we help your experiment?

This pack is in beta testing phase. So, although the instruments are not fully industrialized, we can provide extensive support as part of our beta testing program. Get in touch to see if you are eligible.

Funding and Support

This project has received funding from the European Union’s Horizon research and innovation program under the Marie Skłodowska-Curie grant agreement no. 101119956 (DarChemDN).

Products & Associated Accessories

FAQ - Droplet generator pack

So what is a droplet generator pack in microfluidics?

It is a pre-assembled microfluidic system that is used to produce droplets (usually one liquid suspended in another immiscible liquid) in a controlled, reproducible manner. In practice, it integrates stable flow actuation (pressure control), real-time flow measurement (inline flow sensor), fluid reservoirs, connections, a dedicated microfluidic chip, software, and a user guide in one- so you spend less time improving your plumbing and more time fine-tuning the droplet size and stability.

What are the droplet qualities that I can ever hope to achieve?

The object is high monodispersity: the pack is claimed to be able to produce droplets with a coefficient of variation of less than 3% (CV < 3%). That is, as soon as your conditions of fluids and surfactant make sense, the droplet population ought to be concentrated and not everywhere. That difference is more in droplet work than people would like to acknowledge, particularly when you are quantifying at the downstream.

What does the set up include (and what does it not)?

These will include: a flow sensor (Galileo), pressure controller, reservoirs, tubing and fittings, a microfluidic chip, software and a step-by-step user guide.

omitted (usually): your imaging system. To see droplets and confirm regimes (particularly when first tuning or changing fluids), you will require your own microscope/camera set-up.

Can it do more than emulsions of oil-water?

The most traditional starting point is oil-water, but the point of the pack is now more general: cell encapsulation, emulsions, droplet sorting processes, particle synthesis, and the like, droplet-based microfluidics. The restrictive factors tend to be your chemistry (type of surfactant to use, wettability, viscosity, solvent selection) and surface properties of chip/channel-less the idea of the instrument pack itself.

Is there a tangible description of operating conditions (numbers and not vibes)?

Yes. An example of a use-case is given where hexadecane is used as the continuous and water as the dispersed phase in a cross-junction microfluidic channel to produce water-in-oil droplets. One of such condition is: water 1 uL/min and oil 1.5 uL/min, where the droplet is core-based with a diameter of about 40 um (scale bar 100 um). An additional sample talks of mineral oil containing 2% SPAN 80 to form droplets. It is not that you are to follow those very fluids but that it is the system that is supposed to make the regimes quantifiable, repeatable.

The reason why pressure-driven flow control is used rather than syringe pumps?

The sources of pressure used to generate droplets can be droplet sources based on syringe pumps, peristaltic pumps or droplet sources. The repeated problem is stability droplet size is extremely sensitive to changes in flow rate and many of the it worked yesterday failures are due to small pulsations or drift. Control based on pressure is the control mode of choice when a smoother actuation is needed; and when you do adopt syringe/peristaltic pumps, inline flow sensing is the restraint of sanity, since the set point of a pump is not necessarily the flow that is actualized.

Which are the principal technical specifications that researchers are concerned about?

Pressure control range: -400 to 600 mbar

Pressure stability: 0.2 mbar

Flow rate capability (system-level): 0.1 uL/min to 5 mL/min.

Partial ranges of flow-sensors (5% error, depending on configuration): 0.5-60 uL/min, 2-150 uL/min, 40-1200 uL/min, and 0.5-10 mL/min.

Internal volume of sensor: about 40 uL (depends on setup)

Operation pressure: to 3 bar gauge (maximum up to 6 bar gauge)

Software: separate GUI that can be used in visualization/logging, optional Python API.

Also worth saying (it influences the procurement decision): the flow-sensor technology is characterized as beta, i.e. the specs can change.

I do not receive droplets, or they appear to be wobbly. What are the most common first fixes?

Check that flow rates are within the proper range (not necessarily what the controller reports, but what the sensor is measuring).

Before starting, the channel should be flushed/cleaned; otherwise, any residual contamination or partial wetting will affect everything.

Depending on the surfactant’s concentration and its compatibility across all phases, it may result in coalescence, satellite formation, or none at all.

If none of these were the problem, the next suspects are: wettability mismatch (hydrophilic/hydrophobic surfaces), viscosity ratio, and invisible microbubbles.

What type of assistance can you offer- particularly when we are in our infancy on droplet microfluidics?

The pack is said to be in a beta testing stage, which has its advantage in a practical sense; the team can offer unusually hands-on support as part of a beta program (as long as they are eligible). That advice can save weeks in research groups that are struggling to transition between the phase of having read the papers and having the capability to run this on a daily basis.