Syringe, peristaltic, or pressure microfluidic pumps: which one is the best?

Author

Celeste Chidiac, PhD

Publication Date

Keywords

microfluidic pumps

syringe pump

peristaltic pump

pressure pump

continuous flow

flow rate

Need advice for your microfluidic pump?

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

Introduction

Selecting the right pump is crucial for achieving precise and consistent flow in various applications, from biological research to chemical processing. Syringe, peristaltic, and pressure microfluidic pumps each offer distinct flow characteristics, making them suitable for different experimental needs and conditions. Understanding the strengths and limitations of each can help you make the best choice for your specific application.

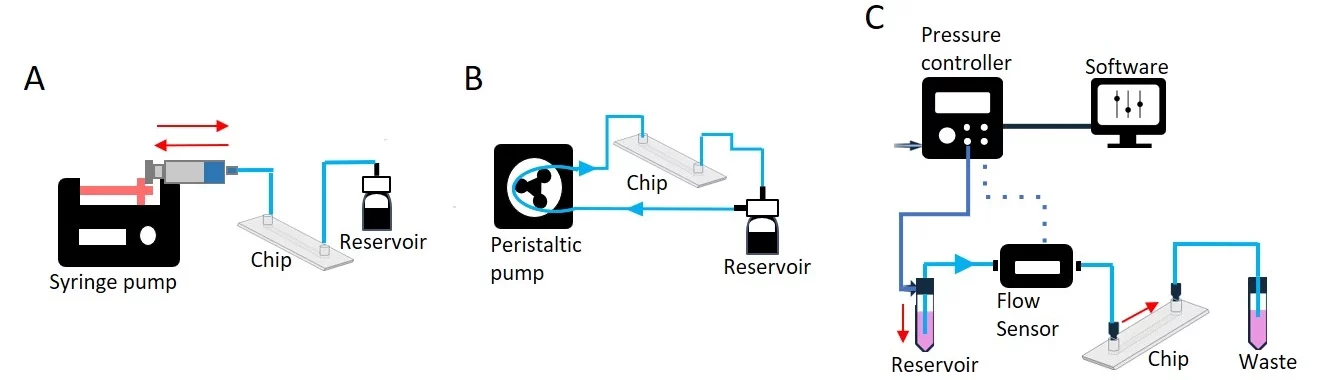

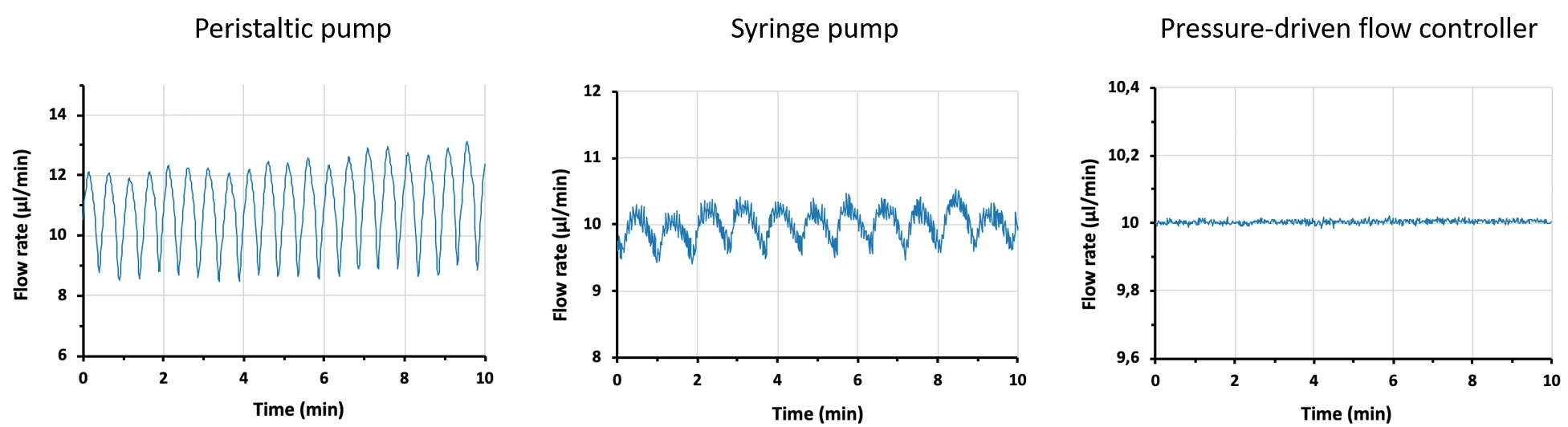

Microfluidic pumps system | Flow profile | Flow rate | Flow rate control | Flow continuity |

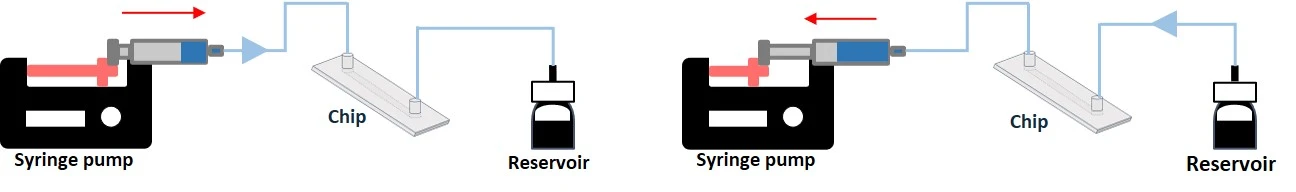

Syringe pump | Oscillating, pulsatility depends on the pump | Suitable for low flow rates | Precise, controlled by the pump | Disrupted when pull/push transition or when syringe empties |

Peristaltic pump | Pulsatile, can be reduced with a dampener | Not suitable for low flow rates | Moderate, controlled by the pump and tubing selection | Continuous flow, can be disrupted when refilling reservoirs* |

Pressure pump | Highly stable profile; Variety of flows possible: pulsatile, steady, stepwise, custom | Suitable for both low and high flow rates | Very precise; Uses a flow sensor feedback loop | Continuous flow, can be disrupted when refilling reservoirs* |

*Infinite volume looping in a recirculation setup

Syringe microfluidic pumps

Flow profile: Oscillating

Working principle: Syringe pumps push or withdraw fluid through a microfluidic channel using an electric motor and syringe plunger. Programmable pumps allow for custom flow profiles.

Characteristics/Considerations:

- Constant flow rate, even with varying resistance

- Suitable for precise control and low flow rates (µL/min to mL/min)

- Flow is disrupted when the syringe is empty and during push/pull transition.

- Flow rate not monitored in real-time; calibration may be needed

- Applications: Drug delivery studies, microfluidic cell assays, and analytical measurements.

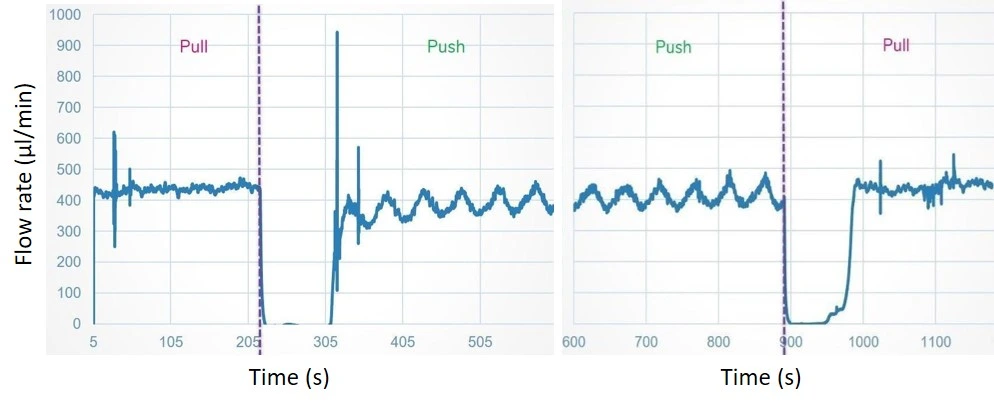

Peristaltic microfluidic pumps

Flow profile: Pulsatile

Working principle: In peristaltic microfluidic pumps, fluid is pushed through flexible tubing by rollers compressing and releasing the tubing.

Characteristics/Considerations:

- Continuous flow

- Moderately pulsatile flow; can be reduced with a dampener

- Suitable for shear-sensitive fluids

- Less precise than syringe pumps and pressure controllers, especially at low flow rates

- Requires calibration for stable flow rate

- Applications: Handling chemicals and long-continuous flow applications, such as cell perfusion.

Pressure microfluidic pumps

Flow profile: Pulsatile, steady, stepwise, customized

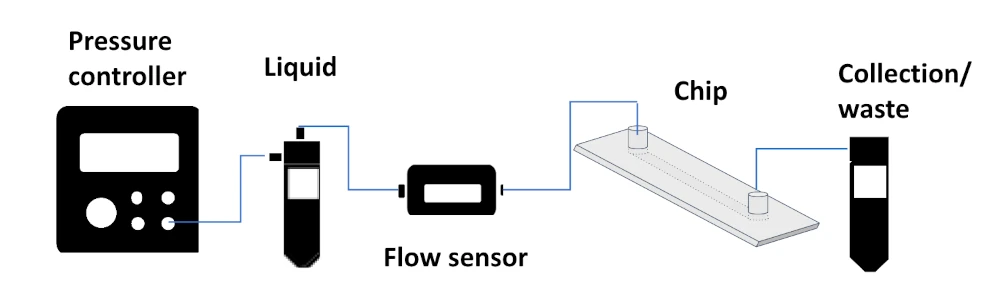

Working principle: Pressure pumps control pressure to drive fluid through microfluidic channels, allowing for dynamic flow control.

Characteristics/Considerations:

- High precision and fast response

- Continuous and constant flow with a stable pressure source

- Suitable for both low and high flow rates

- Flow rate influenced by channel resistance or fluid viscosity

- More costly and complex compared to simpler systems

- Applications: Droplet generation, rapid mixing, cell-based assays, and perfusion systems.

The MIC pressure pumps

The MIC has 3 pressure pumps with different characteristics.

Perfusion pump

-

Our perfusion pump is based on a pneumatic piezoelectric micropump with air compression.

-

Incubator-friendly: can be placed inside the CO₂ incubator and is designed to withstand the humidity and temperature for prolonged periods.

-

The user can choose different flow profiles (pulsatile or linear) to mimic physiological conditions.

-

Compact footprint with up to 6 chips to run multiple conditions simultaneously.

-

Integrated pump + flow sensor, reducing tubing and connectors, and making setup simpler and more reproducible.

-

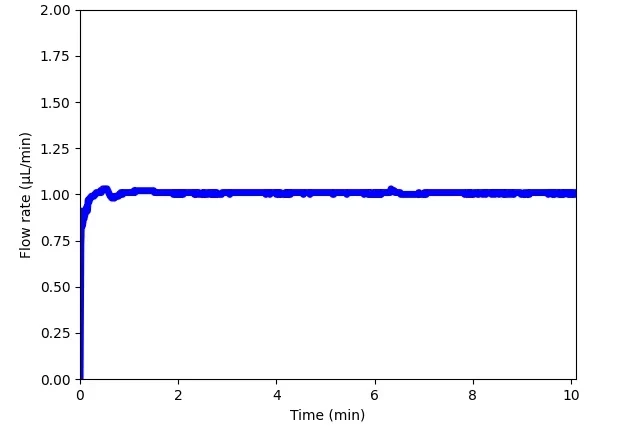

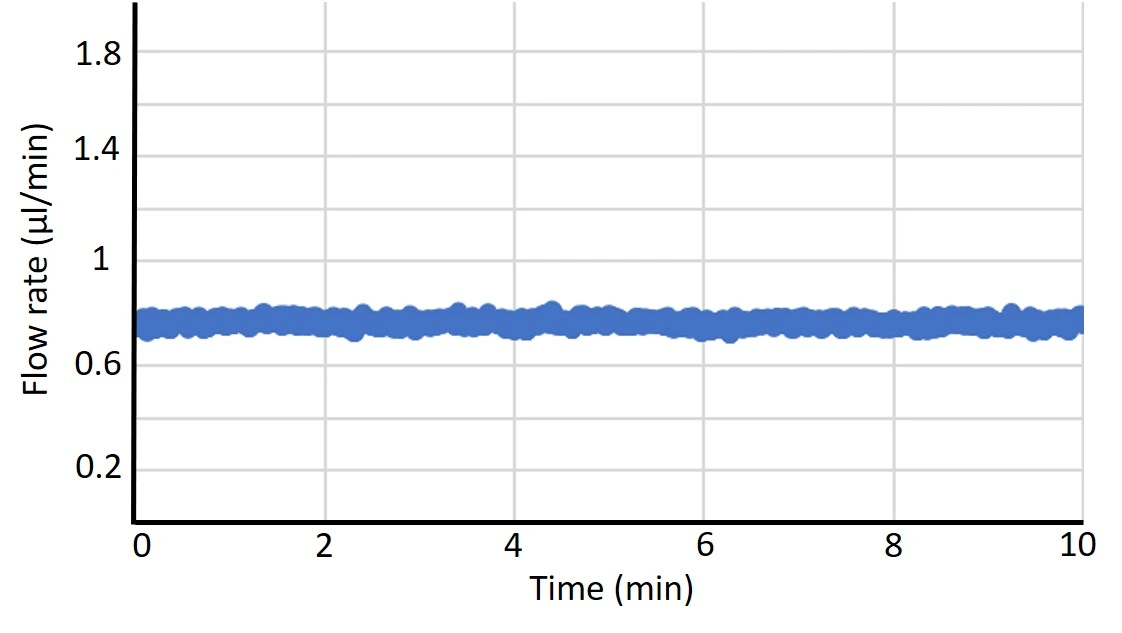

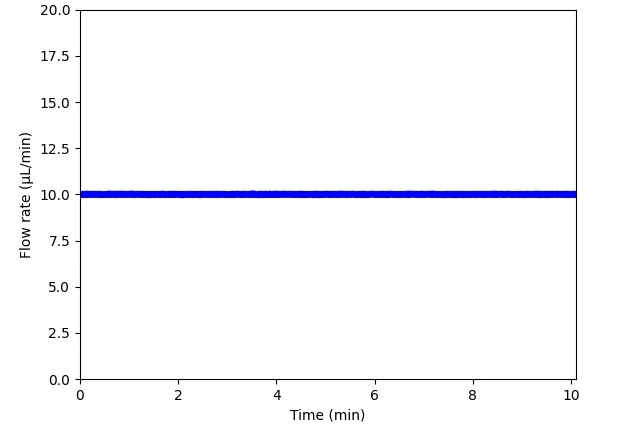

Technical specs: flow rates from 0.1 µL/min to 5 mL/min, with pressure control (0-2000 mbar) and a monitoring/feedback loop.

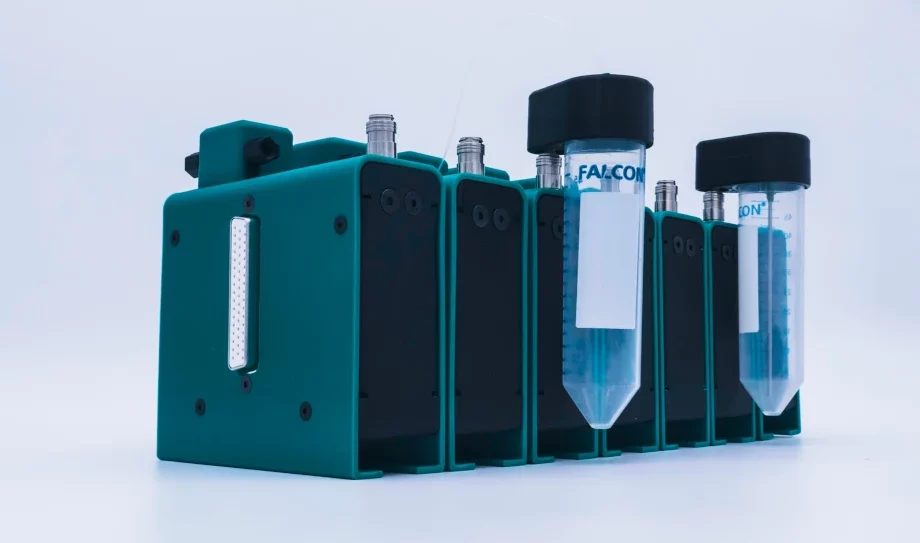

Mini pump

-

Our mini pump uses a pneumatic piezoelectric micropump with liquid compression.

-

Designed to facilitate media recirculation for long-term cell culture in the CO2 incubator (e.g., organ-on-chip, shear-sensitive lines).

-

Compatible with a wide range of reservoir volumes (from small Eppendorf tubes to 1 L bottles) and two main modes: (a) closed-loop using one reservoir, or (b) reservoir-to-waste system using 2 reservoirs (adding level sensors can be switched to recirculation)

-

Technical specs: flow rates down to ~1 µL/min, maximum pressure up to 500 mbar.

Cell culture pressure pump

-

Our cell culture pressure pump is based on proportional valves.

-

Designed for perfusion of cell cultures outside of a CO₂ incubator, while maintaining a constant pH and gas concentration (e.g., 5% CO₂) in the media reservoir.

-

It allows the user to pressurize the media reservoir with a defined gas mix, so that the gas doesn’t equilibrate with the ambient atmosphere.

-

Multiple channels (1-4) with flow sensors and a feedback loop between pressure and flow rate.

Want to know more on this subject? Check the extended review comparing the different microfluidic pump flow profiles and characteristics.

Conclusion

Each type of microfluidic pumps – syringe, peristaltic, and pressure – offers unique advantages depending on the application. Syringe pumps offer precise control at low flow rates but can experience disruptions during transitions. Peristaltic pumps are ideal for continuous flow and sensitive fluids but lack precision and cannot handle very low flow rates. Pressure pumps provide flexible, fast response for dynamic control but are more complex and costly. Carefully evaluating the requirements of your experiment will help determine the most suitable pump for achieving optimal results.

This “quick tips” was written by Celeste Chidiac, PhD.

Published in January 2025.

Contact: Partnership[at]microfluidic.fr

Check more Quick Tips

FAQ - Syringe, peristaltic, or pressure microfluidic pumps: which one is the best?

Is it possible to have one best microfluidic pump to use in research?

The best choice is based on the purpose of your flow: maintain a steady one by several hours, react quickly to a setpoint adjustment, be gentle on cells, or operate at ultra-low flow rates without drifting. Most labs practically use at least two methods (usually syringe to check out at early bench, pressure to check out just about anything that requires tight dynamics and peristaltic to check out recirculation/perfusion routines).

How do you find the most viable option between syringe, peristaltic and pressure pumping?

I would begin by asking three questions:

-Do you really need a stable (low pulsation) flow, or do you really desire a waveform (pulsatile / stepwise)?

-Are the flow rates (sub-uL/min to a few uL/min) being low (sub-uL/min) or predominantly high throughput?

-Is it a long-run recirculation/perfusion system or a simple reservoir (finite volume) experiment?

These three limitations tend to lead to decisions without even a glance at the brands.

What is the behavior of a syringe pump in microfluidics, in reality?

Syringe pump usually provides a highly controlled mean flow rate and is particularly comfortable at low flow (uL/min up to mL/min). The trade off is that the flow profile itself is intrinsically oscillating in the sense that it can be discontinued at push/pull transitions (when you are doing withdraw/infuse cycles) and ceases to exist when the syringe is empty. One more little thing: the flow rate is not often measured in real time, and thus, when your channel resistance varies (bubbles, partial blockage, viscosity drift, etc.), you might not pick it up without measuring pressure or attaching some external sensor.

What is the correct time to use a syringe pump?

Common cases:

-You desire simple and direct dosing when carrying out assays and measurements of analysis.

-It is early-stage prototyping, and you would like something that is familiar and easy to script.

-You require low flow rates and you can afford the working out of operational downtime (refills, transitioning).

-Syringe pumping can perplex even those who think it should not much sooner than you have found that a very sensitive experiment is very sensitive to short interruptions (some droplet workflows, some cell perfusion regimes).

Why do we really need a peristaltic pump in the microfluidics?

Little or no syringe running out, and a most natural fit recirculation. Peristaltics force fluid through rollers compressing flexible tubing, a fact that also makes them useful in shear sensitive fluids (manipulated with caution, using the correct tubing and conditions). The trade-off is pulsatility. You can diminish it by a dampener, and you will hardly ever remove it altogether, and precision at low flow rates is not the strong point of the peristaltic pump.

What is different with pressure pumping as opposed to syringe or peristaltic?

The most common use of pressure-driven microfluidics systems tend to be the most versatile as they can generate flow of a very steady nature and be switched between flow profiles (steady, pulsatile, stepwise, custom) as well. They are also scaling well in both low and higher flow regime. The point is that the control of pressure does not ensure the definite rate of flowing: the real flow rate is determined by the hydraulic resistance and viscosity. This is why serious pressure systems generally are based on flow sensing and a feedback control (pressure changed dynamically to reach flow setpoint).

Assuming that pressure pumps are so good, why does not everyone use them by default?

Difficulty and high price, as well as a somewhat higher learning curve. You are dealing with sources of pressure, multiple channels, sensors and control loops. That is excessive in some of its simple experiments. However, when you require that you want to repeat it on other days, monitor dynamic perfusion curves, or much more powerful automation, pressure control no longer feels like a luxury and begins to feel like the new standard.

In a single comparison, what are the differences of the flow profile?

Syringe pump: tends to be accurate on average flow, however it is likely to exhibit oscillation and may be disturbed by refill/transition events.

Peristaltic pump: constant delivery, yet pulsatile in nature (dampeners can be used), with small flow rates usually weaker.

Pressure pump: it is probably the most stable and responsive, and may deliberately form a range of flow waveforms; flow-sensor feedback often has the best results.

Which options of pressure-based Microfluidics Innovation Center (MIC) focus on, and what are the more specific specifications?

1) Perfusion pump (incubator-friendly)

-Constructed based on air compression pneumatic piezoelectric micropump.

-Made to withstand the humidity/temperature of a CO2 incubator.

-Allows the choice of flow profiles (pulsatile or linear) to replicate physiology.

-Small size, a maximum of 6 parallel running chips.

-Built in pump and flow sensor to minimize tubing/connectors and enhance reproducibility.

-Technical range: 0.1 uL/min -5 mL/min, pressure control 0-2000 mbar, and monitoring/feedback.

2) Mini pump (recirculation focused, incubator application)

-Liquid compression pneumatic piezoelectric micropump.

-Media recirculation Construction Built into long-term culture (organ-on-chip, shear-sensitive lines).

-Helps to support high volumes of reservoir (small tubes to approximately 1 L bottles)

-Two types of operation, closed-loop (single reservoir) or reservoir-to waste (two reservoirs); and with level sensing, automated operation may be switched to recirculation.

-Technical: 0 to 2 -1/min, top pressure: 500 mbar

3) Cell culture pressure pump (no incubator perfusion with gas)

-Based on proportional valves.

-Focused on perfusion without a CO2 incubator but at fixed pH / gas concentration in the media reservoir (e.g. 5% CO2).

-Gasifies the reservoir with a specified gas mixture to avoid the easing of the medium with the ambient air.

-Normally 1-4 channels, flow sensors and pressure flow feedback loop.

When I am preparing a Horizon Europe proposal, what would I do with the term pump choice to make it a valid methodology section?

Reviewers tend to react to relating the pump technology to quantifiable risk decrease:

-Determine the flow stability that is needed and the range (low-flow or high-flow).

-Indicate necessary dynamic profiles (steps, pulses, ramps) and your validation of them (flow sensing, logged traces).

-Reproduction Continuity risks: How to refill events, long-term drift, tubing fatigue, bubble management, and how the platform design deals with them.

-In case of cell work: clearly explain why you have to shear the medium, use of sterility approach, incubator compatibility (where applicable), and how you would avoid uncontrolled exchange of gases in the medium.

Generally, the success rates in the horizon Europe are in mid-teens. Within such a setting, recruiting an advanced microfluidics SME collaborator does become a silent point of differentiation, not only in terms of engineering and prototyping, but also towards de-risking the work plan, elucidating the exploitation/valorization pathways, and narrowing the technical story.