How to choose your recirculation system?

Author

Celeste Chidiac, PhD

Publication Date

Keywords

recirculation system

hydrostatic pressure

syringe pump

Peristaltic pump

pressure pump

Need advice for your recirculation system?

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

Introduction

Fluid recirculation is essential for organ-on-a-chip and microfluidic applications, as it ensures the physiological transport of nutrients, drugs, and cell secretions.

Various systems are available, and choosing the most suitable option depends on the specific application, including factors like flow rate profile, accuracy, and user-friendliness. Recirculation systems can operate using hydrostatic pressure, a syringe pump, a peristaltic pump, or a pressure pump.

Characteristics/ Recirculation systems | Flow directionality | Flow rate control | Flow profile |

Hydrostatic pressure | Normally bidirectional with a rocker | None to limited; Can be controlled using a programmable rocking platform | Affected by rocker speed and tilt angle, and/ or reservoir height and liquid volume |

Infuse/withdraw syringe pump | Normally bidirectional | Controlled by the pump | Amplitude of screw-motion; pulsatility depends on pump |

Peristaltic pump | Unidirectional flow | Controlled by the pump | Moderately pulsatile flow; Can be reduced with a dampener |

Pressure pump and valve | Unidirectional flow with the use of a valve | Precise flow rate control; Uses a flow sensor feedback loop | Highly stable profile; Variety of flows possible: pulsatile, steady, stepwise, custom |

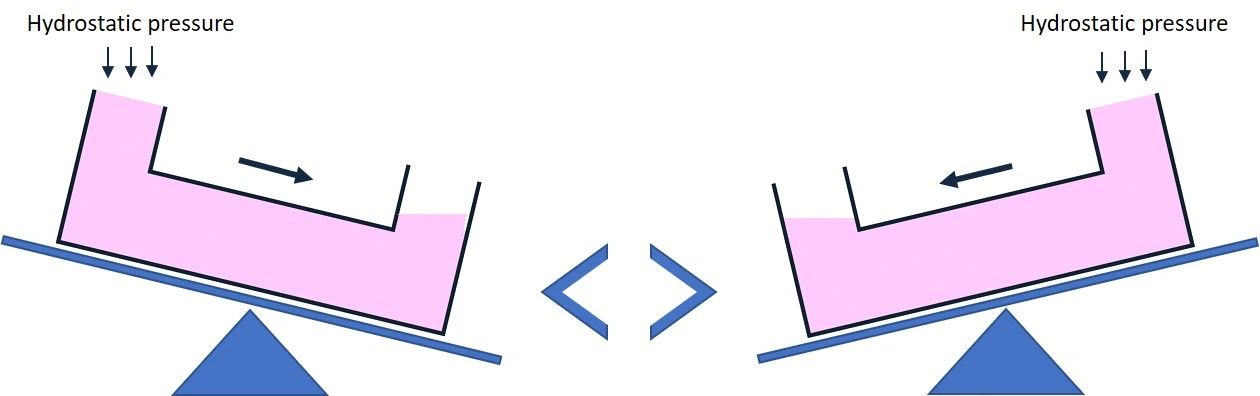

Hydrostatic pressure recirculation system

- Mechanism: Flow is generated by a height difference between the inlet and outlet. Switching the height difference reverses the flow direction.

- Characteristics/Considerations:

- Simple to implement, requiring no electronics.

- Cost-effective and accessible, suitable for basic setups.

- Bidirectional flow.

- A rocking platform can be used to control the back-and-forth fluid movement.

- Difficulty in precisely controlling or predicting flow rates.

- Flow rate estimation is highly variable, limiting reproducibility.

- Applications: Ideal for preliminary experiments or where precision is less critical.

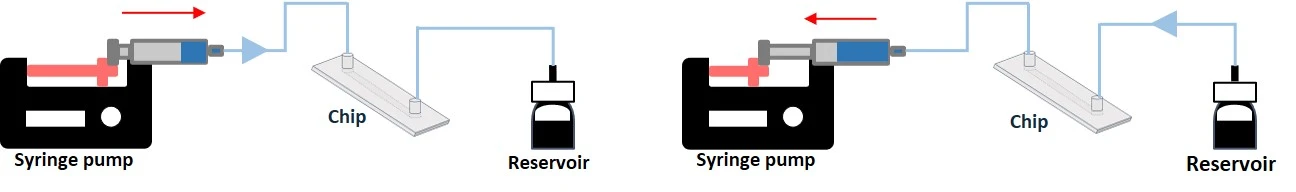

Syringe pump recirculation system

- Mechanism: Syringe pumps push or pull fluid through a microfluidic device with programmable flow rates. Bidirectional systems use multi-syringe setups for continuous push-pull cycles.

- Characteristics/Considerations:

- Programmable flow rate control.

- Bidirectional flow with a push/pull system.

- Flow oscillations caused by motor steps can affect sensitive applications.

- Syringe volume limits the duration of experiments; frequent refilling may disrupt workflows.

- Applications: Well-suited for long-term experiments needing precise flow control, such as cell culture studies.

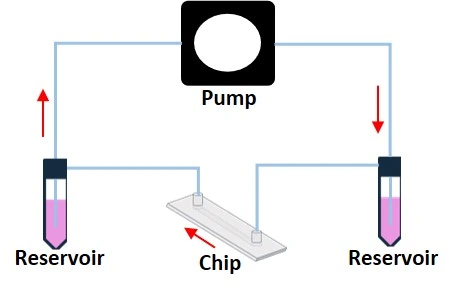

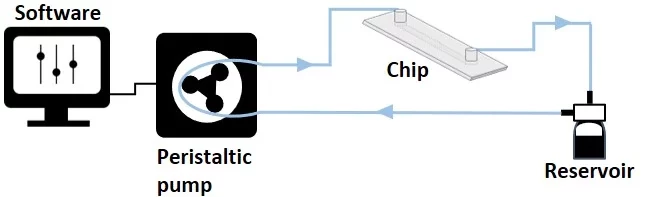

Peristaltic pump recirculation system

- Mechanism: Fluid circulates through a closed-loop system, maintaining steady liquid levels.

- Characteristics/Considerations:

- Simple and user-friendly setup for unidirectional flows.

- Generates pulsatile flow due to the pump’s rotor motion, which may affect particle or cell integrity.

- Pulsation dampeners can be added to achieve smoother flows.

- Applications: Used in cell culture and particle studies where unidirectional flow is needed or pulsatile flow is acceptable.

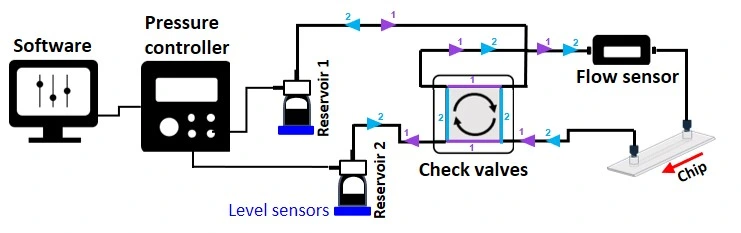

Pressure-driven recirculation system

- Mechanism: Flow is created by a pressure differential (ΔP) across the circuit, controlled by a pressure pump.

- Characteristics/Considerations:

- Configurations include bidirectional open-loop systems or unidirectional setups with valve integration.

- High precision and stability in flow rates, enabled by feedback-controlled pressure systems.

- Versatility in controlling flow paths using valve systems.

- Requires technical expertise and equipment, including flow sensors and controllers.

- More costly and complex compared to simpler systems.

- Applications: Ideal for advanced and highly controlled experiments, such as organ-on-a-chip systems with strict physiological requirements.

Want to know more on this subject? Check the extended review comparing the different recirculation systems.

Conclusion

The choice of a suitable recirculation system should be guided by the application’s specific requirements. Hydrostatic pressure systems offer a simple and cost-effective solution for basic experiments, while syringe pumps provide precise flow control for long-term studies, with limitations in duration and flow smoothness. Peristaltic pumps are user-friendly and suitable for applications tolerating pulsatile flow, and pressure-driven systems excel in precision and flexibility for advanced setups. By aligning the characteristics of these systems with experimental needs, researchers can optimize the performance and reproducibility of their microfluidic and organ-on-a-chip studies.

Funding and Support

This review was written under funding from the European Union’s H2020-LC-GD-2020-3, grant agreement no. 101037090 (ALTERNATIVE, project page).

This “quick tips” was written by Celeste Chidiac, PhD.

Published in January 2025.

Contact: Partnership[at]microfluidic.fr