Our microfluidic skills: Organ-on-a-chip system

Author

Camila Betterelli Giuliano, PhD

Publication Date

February 27, 2025

Keywords

Organ-on-a-chip

Cell culture

Bioreactor

Flow control

Co-culture system

Placenta-on-chip

Lymph node-on-chip

CO2 incubator

Barrier platform

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

Microfluidics gained momentum as the future backbone of biotechnology and life sciences because it scales down assays to the order of magnitude of the cell, amplifying signals that would be otherwise impossible to detect.

Organ-on-a-chip system was born from this principle. Conventional cell culture handles cells in bulk and in an oversimplified environment that does not resemble the human body. When we move to animal studies, the models are complex but not equivalent. Adding microfluidics to cell culture increases complexity without losing control. You can co-culture human cell types usually found together in the body in nearby chambers so the secreted molecules can interact with the cells in a timely manner. You can add flow to mimic bodily fluids. You can add stretch or compression to mimic mechanical forces.

The benefits are only starting to be explored, but we, as the MIC, have a lot of experience in implementing a complex organ-on-a-chip system for a variety of applications in the frame of European projects.

Alternative, heart-on-chip to elucidate chemical exposure

The project Alternative is part of the Green Deal and focuses on understanding how chemical exposure affects cardiac tissue in a heart-on-chip model. We developed a microfluidics platform so our partners can culture cardiac tissue in bioreactors with sensors.

The platform allows them to run four bioreactor cultures in parallel in an automated manner, so the experiments can run for long stretches of time. Then, they expose the cells to cardiotoxic industrial chemicals and pharmaceuticals, and analyse the readings of the sensors (GA no. 101037090).

Tumor-LN-on-Chip, lymph node-on-chip for metastasis studies

Metastasis is a major problem in cancer patients. Cancer cells can use the lymphatic system to spread and colonize other parts of the body, but the mechanisms behind it are not well understood. And that’s the goal of the Tumor-LN-on-Chip project (GA no. 953234).

To study motile cells, being close to the microscope was a must. However, most microscope incubator chambers are not designed to fit microfluidics equipment. So, we designed a setup that would allow our collaborators to be independent of the CO2 incubator and the environmental chamber of microscopes as well, while keeping ideal culturing conditions for cell culture.

With it, our partners managed to culture lung cancer cells for 16 days outside the incubator.

LIFESAVER, placenta-on-chip to test effects of chemical pollutants on fetuses

The project LIFESAVER is also part of the Green Deal, but focuses on the communication between mother and fetus in a placenta-on-chip model to understand how toxic chemicals cross the placental barrier (GA no. 101036702).

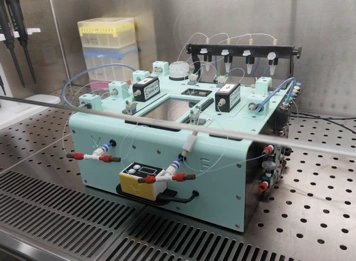

The MIC developed a barrier platform that allows them to recirculate media independently, measure O2 levels, and collect samples in a time-resolved manner. All on both sides. Communication between the mother side and the fetus side happens in a specialized membrane in a organ-on-a-chip system developed by one of the project partners.

Want us as partners in your project for 2026-2027 call?

Curious what's next? Sign up for our Newsletter

FAQ – Organ-on-a-chip system

What is an organ-on-a-chip System?

An organ-on-a-chip is a small, fabricated device that mimics the function of actual human tissues, albeit in the lab. We do not cultivate cells in a standard dish; instead, we cultivate various types of human cells in miniature, interconnected chambers. These chambers are then filled with fluids that mimic blood or other body fluids, and we can even perform physical actions such as stretching or compression. The outcome is a model of human organs that are realistic and controllable, and much closer to what happens within the body.

What is the advantage of microfluidics over standard cell culture or animal testing to understand the functions of organs?

It is all about size and manipulation. Microfluidics enables us to operate at the single-cell level, enhancing precision and allowing us to observe changes over time with extraordinary accuracy. The data are more consistent and meaningful than in normal cell cultures. And with human-specific results and the ability to carefully manipulate experimental conditions, this is almost unattainable in animals.

What type of systems has MIC already developed?

How very broad our applications are, here are three of them:

- Heart-on-a-chip: A heart-on-a-chip is a platform that operates four smaller multiculture heart tissues, each with sensors, and is used to determine the effects of drugs and chemicals on the heart.

- Lymph-node-on-a-chip (Tumor-LN-on-Chip): It is designed to allow scholars to study cells through a microscope without removing them from their natural environments. In this configuration, our colleagues have cultured lung cancer cells for more than 2 weeks.

- Placenta barrier-on-a-chip: A model of the maternal-fetal barrier that constantly measures the oxygen levels and keeps track of the movements of various substances between the two parts.

What is so special about your systems that they are instrumented, rather than just a bunch of fancy microchannels?

We are designing them to have sensors and controls built in. It implies the real-time tracking of flow, pressure, and oxygen, automated media exchange, the ability to integrate with real-time imaging, and even mechanical stimulation (such as tissue stretching). All the things are consolidated into a single controlled environment.

Do your systems have the capability to run long experiments without supervision?

Yes. Our systems are configured to be stable and automated. Parallel bioreactors, bubble-resistant channels, and software-controlled fluid systems enable them to run for days or even weeks. It implies a reduced number of manual manipulations and more reliable, less contaminated data sets.

What is the communication of different cell types with one another (co-culture)?

The way we construct the chips is such that cells are in adjacent chambers, which are separated by semi-permeable barriers. This allows the free flow of molecules and signals between them, just as occurs in the body. In the same way that cells are in real tissues, with fine-tuning of fluid flow and timing, we reproduce the same physical and chemical environment.

Can these systems work directly under a microscope without needing a full incubator?

Yes. We have constructed a small environmental control unit for temperature, humidity, and gases that is easily placed on the microscope stage. This implies that you can observe the living cells as they are without having to interfere with their surroundings. It is a straightforward way of addressing a general problem in live-cell imaging.

We already have the chips - could you just supply the control system?

How does this help build a competitive Horizon Europe proposal?

Two main strengths:

- Credibility of the technical plan – receive deliverables in operational organ-on-chip systems and with clearly established validation standards.

- Impact – Our systems generate human-relevant data, reduce the need for animal testing, and accelerate the translation of research.

The introduction of MIC as an SME (small or medium enterprise) partner brings actual implementation capability – this is what the reviewers seek. Proposals that involve us have, on average, a success rate twice that of the average proposal.

What is the MIC approach to the IP (intellectual property) in EU projects?

We adhere to EU regulations and observe the agreements made within the consortium. We are not rigid; we adapt to the project’s requirements.

Is the MIC capable of supporting the scale-up or industrialization of the prototype?

Our primary business is prototyping. In the case of industrialization, we can introduce you to either partners or manufacturers with whom we have worked.