Our microfluidic skills: Microfluidic flow control

Author

Camila Betterelli Giuliano, PhD

Publication Date

February 27, 2025

Keywords

Intelligent Microfluidics

Deep Learning

Microfluidic Devices

Artificial Intelligence

Machine Learning

Fluid flow control

Pressure-driven pumps

Incubator-friendly

Flow sensor

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

Controlling microfluidic fluid flow can be crucial for many biological assays, chemical analysis, and material synthesis applications. Microfluidics is the technology that controls liquids at the micro scale where laminar flow dominates. Its pattern predictability and low mixing capabilities allow researchers to perform complex liquid manipulations at a very precise rate.

Different pumping systems can generate various flow profiles, each with unique characteristics suited to specific experimental requirements. Steady flows are useful for applications requiring high precision while pulsatile flows can mimic physiological systems. Choosing the right one depends on your end goal.

At the MIC, we develop microfluidic flow control with the end user as the guiding star. You can see some examples of our recent developments below:

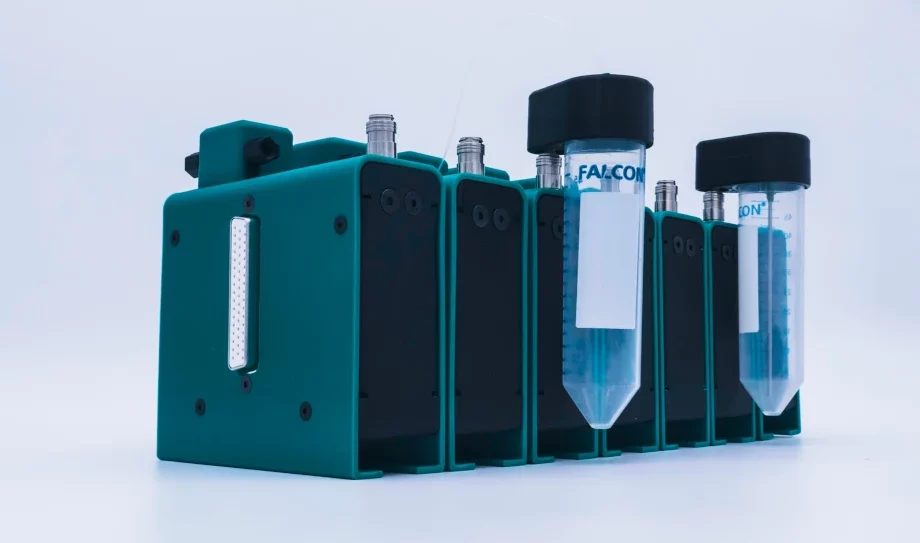

Caterpillar, the modular and incubator-friendly pump for Thor

An incubator-friendly pressure-driven pump that does not require an external compressed-air source, the Caterpillar is modular and ideal for organ-on-chip experiments.

It provides a range of flow profiles and flow rates, increasing the possibilities of mimicking physiological systems without penalizing precision.

It was developed in the frame of the Thor project to continuously perfuse brain organotypic cultures inside the incubator (GA no. 101099719).

However, our Caterpillar microfluidic flow control system also found a remarkable use in the EDAPHOS project to develop a user-friendly, portable C. elegans-on-chip model to assess the ecotoxicity of chemical compounds in soil, developed in collaboration with the French National Institute for Industrial Environment and Risks (INERIS) (GA no. 101112768). If you want to know more about it or about the projects it supports, just follow the links!

Beetle, the gas-keeping pump for incubator-independent work for Tumor LN-on-Chip

Sometimes we need to think outside the box, or rather, outside the CO2 incubator. The Beetle was designed to help you do exactly that.

This pressure-driven pump can be connected to any pre-mixed gas bottle (95% air/5% CO2, for example) and it will pressurize your liquid with it without altering the gas composition. Why is it different from other pressure-driven pumps? Because most pressure-driven pumps require a high amount of gas to keep the pressure constant, and if you work with nitrogen or CO2 (or any other gas), the environment in your lab can quickly become toxic.

If you are not working with cell biology and don’t need a CO2 incubator, but your experiments require precise gas input, this is your pump.

The Beetle was initially developed in the frame of the Tumor-LN-on-chip project. The first version of this technology was validated by our collaborators from the National Technical University of Athens, who successfully cultured Lewis Lung Carcinoma cells outside the incubator for 16 days. You can see our joint results in the Lymph-node on chip pack (GA no. 953234).

A second version of this technology, with improved gas efficiency, compact integration and pH monitoring add-on is now under development for the Bio-HhOST project, to ensure the long term culture of brain organoids by our collaborators from the University of Trento (GA no. 101130747).

If you want to know more about it or the projects it supports, just follow the links!

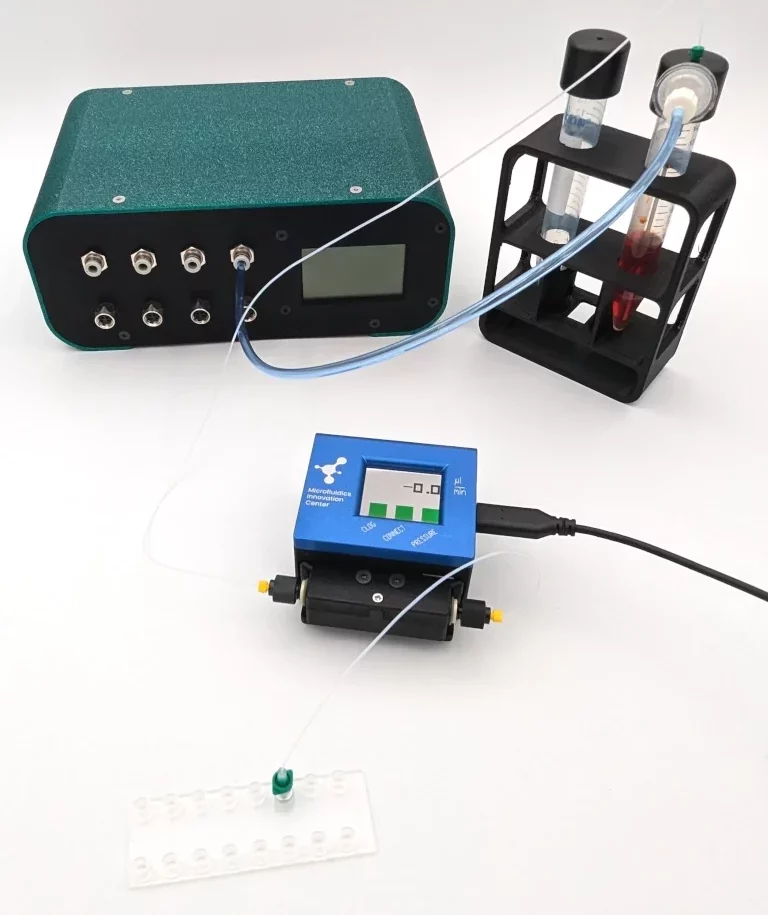

Minipump, the compact and incubator-friendly pump for BioProS

If you have a crowded brain and CO2 incubator, simplicity and small footprint are the words of the day!

The Minipump acts similarly to a peristaltic pump, with 1/10 of the size and considerably more precision. It has one way in, one way out, a screen to control everything and it fits on the palm of your hand.

The minipump was developed in the frame of project BioProS to recirculate media in a compact setup. It is part of one of the sections of the industrial process for virus production and detection, as low footprint was one of the main requirements of the future platform conceived by Fraunhofer IPA. As a bonus, we made it incubator-friendly to cover a larger range of uses for this pump (GA no. 101070120).

Galileo, the next generation flow sensor

Wide range of flow rates without having to buy several flow sensors? That’s only one of Galileo’s upsides. We have separated the electronics of the flow path, so you keep the same base and only change the sensing cartridges.

It also detects when something is wrong inside the flow sensor, alerting you of possible clogging. Moreover, the technology is the most precise and stable from 0.01 µL/min to 30 mL/min.

Too good to be true? All of that is possible because of a brand new technology we developed to address common issues of flow sensor users worldwide. This technology was funded by the EIC Transition GA no. 101113098.

Want us as partners in your project for 2026-2027 call?

Talk to our experts!

FAQ – Microfluidic Flow Control

What is the meaning of “microfluidic flow control” ?

Laminar flow prevails in microchannels, so you have high repeatability for controlling reagents, cells, and particles while achieving very minimal mixing. Good flow control enables you to have steady, pulsatile, or time-dependent profiles and keep them stable for long experiments.

Pressure-driven control or peristaltic-style pumping?

Pressure-controlled systems are used when you need clear, ripple-free flow, quick response when the setpoint changes, and easy multiplexing. Peristaltic-type actuation is appealing for compact, closed-off systems where you need minimal pumping and a “one in / one out” path. Labs end up using both in practice: the pressure for accurate perfusion or organ-on-chip, and the compact miniature pumps for basic recirculation loops.

What are the generally effective flow profiles?

Three flow profiles: (i) steady (constant) flow for long-term culture and dose-controlled assays, (ii) pulsatile or oscillatory flow for simulation of physiological shear (vascular, respiratory models of gut), and (iii) ramp/step protocols for dynamic exposure and sensor calibration.

How does "Caterpillar" pump assist in work for incubator-based organ-on-chip?

Caterpillar is a pressure-driven, incubator-friendly module pump that can coexist with your culture without requiring an external compressed-air connection. It accommodates multiple flow profiles at biologically appropriate rates, allowing you to reproduce the organ-level dynamics without losing precision. It was first designed for continuous brain organotypic culture perfusion but has been adapted for other ecotoxicology and organism-on-chip applications.

I cannot use a CO₂ incubator. Can I have the correct gas composition during perfusion?

That’s the idea behind MIC’s “Beetle” pump. It self-pressurizes fluids directly using a pre-mixed gas (e.g. 95% air / 5% CO₂), holding gas composition stable. It’s appropriate for incubator-independent culture, and has been proven in workflows for tumors and organoid-on-chip.

What is the “Minipump,” and where does it fall?

Minipump is a compact palm-sized unit that acts like a highly compressed peristaltic pump but significantly more precise. It features a single inlet, single outlet, built-in screen, and small footprint, all of which are valuable for recirculation in crowded configurations (e.g., bioprocessing modules, virus lines for manufacturing or detection) where compactness and parsimony are a priority.

Do I need several flow sensors to cover varied ranges?

Not by MIC’s “Galileo.” It’s a cartridge-based sensing path that’s decoupled from the electronics; that way, you change the same base but the sensing element. It aims for high stability and precision from very low flow rates (tens of nL/min) to tens of mL/min. It also indicates partial clogging, so that you’ll know where you are and correct the setup before your experiment goes haywire.

How are these devices interfaced to standard labware and chips?

All the systems are organized around typical microfluidic connectors, reservoirs, and chips. Most groups in practice operate them using typical tubing, check valves, and manifolds. For organ-on-chip, we recommend: pressure source → flow regulation → sensor (option inline) → chip → waste or recirculation. For gas-managed perfusion, position the gas-pressurized stage before the chip and add a small bubble-trap immediately before the inlet.

How do I decide between Caterpillar, Beetle, Minipump, and Galileo for the project?

Incubator-based, multi-profile perfusion with accuracy? Caterpillar.

Want stable gas composition outside an incubator or with individual gas sets? Beetle.

Ultra-compact recirculation required but easy-to-use controls needed? Mini pump

Want broad-range, high-stability flow measurement with diagnostics? Galileo.

If your application falls between two categories (as it often will), we will most likely incorporate a pressure stage (Beetle or Caterpillar) and Galileo sensing, and incorporate a Minipump loop where recirculation is required.

What is the Microfluidics Innovation Center (MIC)?

The Microfluidics Innovation Center, or MIC, is a small to medium-sized enterprise (SME) company based in Paris. It was created in 2011 by researchers from Elvesys. We focus on building custom microfluidic systems and have participated in over 50 European and national research projects. Some of our work has even helped launch 10 spin-off startups.

PS: We are not a consulting firm! Like all project partners, we are only funded if the proposal is selected by the European Commission, and only for the R&D work packages we deliver.

What is the MIC’s experience with Horizon Europe projects?

We’ve been involved in European projects since 2011, starting with FP7, then Horizon 2020, and now Horizon Europe. We’ve joined over 50 consortia, typically as a technical partner, focusing on R&D, prototyping, and helping shape the project’s impact.