Instantaneous mixing in microfluidic reactor: CReaNet

Author

Nisarga Reddy, PhD

Publication Date

April 18, 2019

Status

Keywords

microfluidic mixer

instantaneous mixing

Lab-on-a-chip

pH Oscillator

spatiotemporal control

laminar flow

mass transfer

continuous stirred-tank reactor (CSTR)

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

Microfluidics, because of the small scale, offers an exact way to control chemical reactions, particularly the mixing of reagents.

The MSCA-ITN CReaNet project aims to reproduce a microfluidic mixer to achieve instantaneous mixing and study chemical reaction networks on a chip.

Instantaneous mixing in microfluidic reactor: introduction

Chemical reaction networks serve various complex biological functions such as signaling, protein synthesis, and homeostasis.

These reactions operate far from equilibrium conditions, giving rise to behaviors such as oscillations and pattern formation.

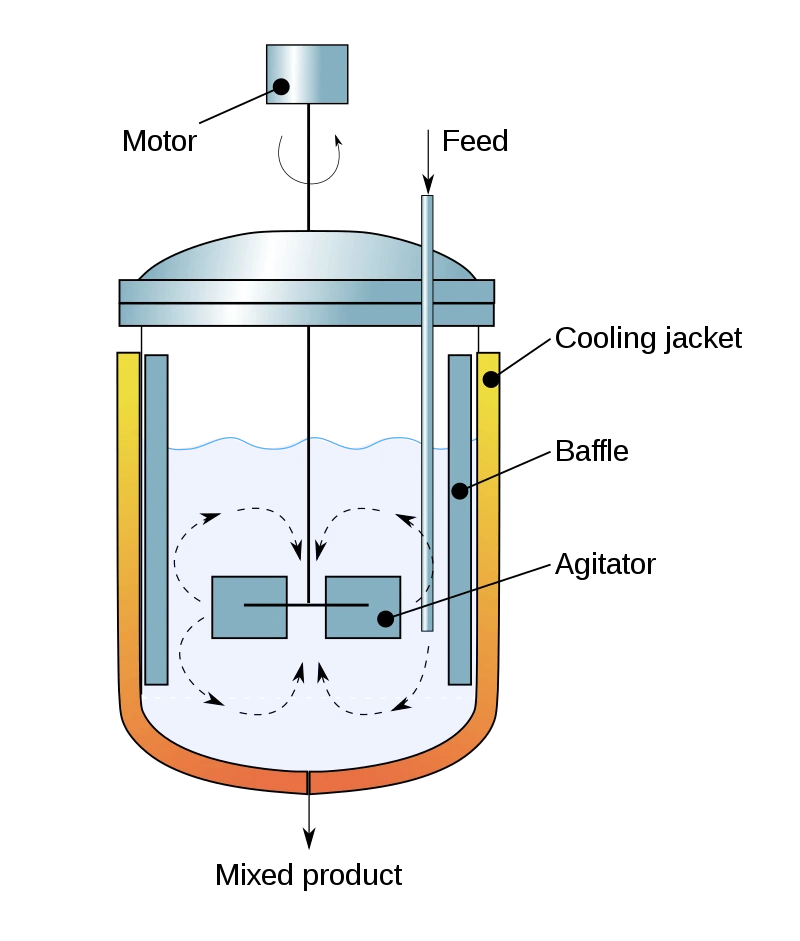

To reproduce them, it is thus essential to design reactors allowing an instantaneous mixing of the reagents. Typically, this is made in a continuously-stirred-tank-reactor (CSTR).

Instantaneous mixing in a µCSTR: project description

A continuous stirred tank reactor is an open reactor fed through two or more inlets with reagents at a flow rate Q. The reagents are supposed to be perfectly mixed in the reactor of volume V, such that each infinitesimal injection of fresh reagents is instantaneously homogenized in the whole reactor. The outlet discards reagents at flow rate Q, thus keeping V constant.

Microfluidics is a technology of choice to provide precise spatiotemporal control of the concentrations of reagents with, typically, ranges of 1µm and 1s and to study chemical reaction networks more precisely.

In this project, we aim first to design a CSTR on chip for the instantaneous mixing of chemical reagents at a microscale and evaluate its mixing capacity. We aim to use this microreactor to propose a microfluidic universal mixer useful for other microfluidics applications.

In the second step, we will integrate up to 6 µCSTRs on a single chip and study the stability of the whole system. Very accurate flow control to feed this mixers’ network will be achieved using the Elveflow OB1 pressure controller. It allows precise and stable flow and pressure control, enabling us to study the optimal reagent concentrations, flow rates, and spatial distribution of the µCSTRs.

The final aim is to implement biocompatible chemical reaction networks in our device. Biocompatible chemical reaction networks have up-and-coming applications, such as signal amplification or biomaterial synthesis. We will, in particular, reproduce a pH oscillator on our on-chip mixer.

This project has received funding from the European Union’s Horizon research and innovation program under the Marie Sklodowska-Curie grant agreement No 812868 (CReaNet project).

Researcher

Nisarga Reddy

PhD Candidate

- Research Engineer FEA (Silgan Dispensing Systems)

- FEA Engineer (SKF)

- Master of Technology in Mechanics & Machine Design ( Visveswaraya Technological University, India)

Areas of expertise:

continuum mechanics, Product design & optimisation, Finite Element Method

Check our Projects

FAQ – Instantaneous mixing in microfluidic reactor: CReaNet

What is the problem that is solved by this reactor?

The mixing, diffusion, and reaction occur simultaneously and on inadequately defined timescales; in other words, conventional reactors confuse cause and effect. These are separated by a microfluidic mixing reactor, which applies fine sequences of mixing events and time delays. It is possible to pump a chemical reaction network (CRN) using programmable pulses, ramps, or oscillations and measure kinetics before gradients are lost.

What is the meaning of the spatiotemporal control in practice?

Spatial: on-chip gradient (Y-junctions, split-recombine, or staggered herringbone mixers) can be used to control the positioning of reactants and the rate of homogenization.

Temporal: flow-programmed feedback, normally sub-second pulses, or periodic actuation, which causes a change of state in the CRN (such as catalyst switching, pH switching, or inhibitor addition) with milliseconds-scale jitter.

What is the mixing speed, and what is the reproducibility of the delays?

Chaotic advection (staggered herringbone) and optimized split-recombine lattice 90-99% homogenization are routinely achieved in 5-50 ms using aqueous reagents at common microchannel dimensions (100-200 μm). There are no residence-time distributions; the coefficient of variation of delay lines is usually less than 3-5% over minutes-long acquisitions, or small enough to solve multi-step CRNs in non-deconvolution gymnastics.

Programming of inputs: How are the syringe pumps, valve, or pressure programmed?

MIC is a proponent of pressure-driven actuation with rapid on-chip valves. Pressure control produces crisp transients (rise times of the order of tens of milliseconds) and has fewer stick-slip artifacts than stepper-driven syringes. In the case of multi-reagent logic, a small manifold of valves directly corresponds to CRN instructions: add, hold, quench, recycle.

What is so peculiar about this being a mixing reactor and not a mixer attached to a channel?

Co-designed geometry and timing are used as the core. Mixers (herringbone, serpentine bends, or Tesla elements) are incorporated into modular units, pulse generators, delay lines, and quenchers, so you can stack the steps as in code. That architecture maintains the Peclet at a high value in the regions of interest (where transport is important, such as injection), and drives diffusion in the quench region to freeze a state to be read out.

What are the expected performance of a new user on a first campaign?

Start envelope realistic: flow 0.1-5 mL.min-1, mixing 10-50 ms (to 95%+ homogenization), delay accuracy ±2-3%, and thermal drift <0.2 °C throughout the functional area with integrated heat-spreaders. You can screen 50-200 conditions on an average day with 10-10,000 cycles of the identical CRN stimulus to construct robust distributions.

What MIC did relative to this project that is unique?

- A collection of geometry modules of mixers and delay lines, which can be changed by switching the entire chip.

- CRN protocols written as playbooks (as automation scripts, e.g., pressure schedules, valve choreography, etc.).

- Results are comparable across labs and months because QA metrics – mixing index, rise time, residence-time CV, and sensor calibration curves can be compared across months. This is supported by MIC’s microfabrication and rapid-prototyping pipeline, which converts ideas into alpha and beta prototypes regularly.

Compare this technique with stopped-flow experiments?

Stopped-flow is ideal for single, rapid mixes; plates are ideal for throughput but not for controlling a transient. The microfluidic reactor does this and that: sub-second-scale transients, repeatability, and hundreds of conditions on a single chip with very little reagent consumption. The reagent savings are typically 10-50x, and the signal-to-noise in early-time kinetics is better because the dead volume is small and the mixing length is millimetric.

What do you require of us to get a collaboration?

Brief dossier: desirable CRN (species, rate-limiting steps), solvent system and viscosity, preferred pulse widths and periods, acceptable shear, target temperature range, readout choice (optical, electrochemical, or sampling). To channel families will be extrapolated to bulk kinetics or Arrhenius parameters, and acceptance criteria (mixing index, delay CV, percent conversion by time-t) proposed by MIC.

What is the place of this in the Horizon Europe projects?

It is a process intensification, environmental chemistry, and green materials called horse. The introduction of a successful SME to a consortium makes it stronger; in various European projects, the inclusion of MIC in the proposal has increased success rates by an order of magnitude as compared to official threshold. We are generally in the lead in microfluidic architecture, automation, and exploitation, and we provide initial prototypes to establish milestones.