Automated high-throughput production of monodisperse emulsions: AutoDropProd

Author

Remigijus Vasiliauskas, PhD

Publication Date

September 10, 2018

Status

Keywords

droplet microfluidics

monodisperse droplets

automated droplet generation

optical methods

emulsions for food industry

monodisperse emulsions

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

Monodisperse emulsions are of great interest to the food industry, pharmaceutical industry, and cosmetics industry as they have increased stability and better-controlled properties compared to polydisperse ones.

Automated monodisperse emulsions generation: introduction

Thanks to the success of the AutoMonoDroplet project, we are now able to automate the production of specific-size droplets at rates higher than 5 kHz in microfluidic chips and precisely control their size, making monodisperse emulsions with a coefficient of variation below 0.2%.

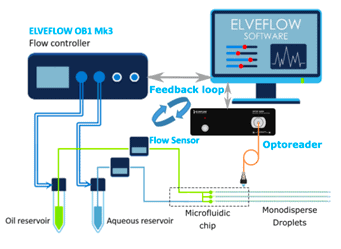

This is achieved by measuring the droplet size using optical methods and constantly adjusting the droplet diameter by changing flow rates and pressures. We are using a fast-response flow controller system (Elveflow) to achieve the best results, thus improving the system’s performance.

Automated monodisperse emulsions generation: project description

The production of monodisperse emulsions in a single channel is already well controlled, so we will concentrate on this new project on high-volume droplet production to meet industrial needs.

We aim to apply parallelized droplet generators in combination with controlled automated droplet production to provide monodisperse emulsions despite any fluctuations in the system (for example, the clogging of a microfluidic channel or other instabilities).

Additionally, using the combination of our developed system with an adjustable chip geometry, one can produce droplets of almost any desirable size using a single chip, thus avoiding droplet size limitation imposed by the channel dimensions.

As a result, we can offer a very versatile, stable, and simple-to-use microfluidic system to generate specific-size monodisperse emulsions at an industrial scale.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 796514 (AutoDropProd).

Do you need more information? Feel free to read Remigijus’ review about droplet detection in microfluidics.

Check our Projects

FAQ – Automated high-throughput production of monodisperse emulsions: AutoDropProd

What is AutoDropProd, simply put?

The microfluidic AutoDropProd system is an automated system capable of producing highly monodisperse emulsions (droplets of nearly identical diameter) at throughputs relevant to industry, using high-throughput optical droplet detection and active control of flow rates and microfluidic chip pressures.

Why should monodisperse emulsions be so important to industry?

Droplet size dictates texture, release profile, stability in food, pharma, and cosmetic products, and even taste or bioavailability. In comparison to polydispersants, which are prone to variation across different areas, monodisperse emulsions (where the coefficient of variation in droplet diameter can be maintained at under 0.2 percent) are much more stable and predictable, which will translate into improved product quality and greater process control.

What is actually the way that AutoDropProd produces and regulates droplet size?

The system is initially based on previous results from the AutoMonoDroplet project, which demonstrated the ability to produce droplets of a specific size at over 5 kHz in microfluidic chips in an automated fashion. Optical techniques are used to measure droplet size in real time, and the controller adjusts flow rates and pressures through a quick response flow controller (Elveflow) in order to maintain the droplet diameter on target. It is this closed-loop architecture that allows for both accuracy and stability over the long run.

What is the difference between AutoDropProd and the traditional single-channel droplet generators?

Individual droplet generators are already under good control in the laboratory, but just not provide good volume to most industrial processes. AutoDropProd even further combines:

- Parallelized droplet generators (running in parallel in a number of channels), and

- Automated feedback control which corrects the instabilities like channel clogging or changes in pressure.

Such a combination enables the system to be monodisperse even in the case where individual channels begin to deviate, which is important as soon as you leave demonstration and move to volumes that are production scale.

Does the same chip produce droplets of different sizes?

Yes. One of the design decisions is the utilization of a variable chip geometry and control plan, which divides the droplet size and permanent channel dimensions. AutoDropProd can produce droplets of nearly any size by adjusting flow rates, pressures, and operating conditions, eliminating the geometric constraints that commonly severely limit droplet size on a single chip. It is particularly important in R&D, where you might want to quickly scan droplet diameters without having to print a new chip every time.

What are the real benefits of food, pharmaceutical, or cosmetic formulations?

To the industrial users, the system means:

- High throughput due to parallel generators and kHz fast rates of droplet formation.

- Very low size dispersion (CV < 0.2%) resulting in increased stability and shelf life.

- Multipurpose droplet size with one hardware platform.

- Instability compensations are automatically done, which saves time and involves manual-re-tuning.

Concretely, it can lead to greater homogeneity in the encapsulation of active ingredients, greater control over mouthfeel or texture, and simplified regulatory documentation due to tighter characterization of the product.

What is the technical part of MIC in AutoDropProd?

Microfluidics Innovation Center (MIC) Colocation Microfabrication, flow control, and automation:

- Microfluidic chip and droplet generators design and optimization.

- Combination of optical droplet counting with rapid electronics control.

- Monodispersive emulsions in realistic and noisy feedback algorithm implementation.

This engineering/application expertise is precisely what MIC brings to the majority of Horizon Europe and Marie Sklodowska-Curie projects where its participation as an SME partner has been linked to an approximate two-fold improvement in proposal success rate in comparison to official EU baseline data.

Real-time control of the system?

The droplets are observed optically (usually via imaging or scattering-based methods), and their sizes are compared with a specified target. In the event of a deviation, the system corrects flow rates and pressures using a fast-response controller (e.g., Elveflow hardware), returning droplet size to within specifications. Due to the closed, fast loop, the system can track slow drifts and abrupt perturbations and sustain monodispersity during extended runs.

Is it a finished commercial product or a prototype platform?

On the MIC side, the project is already considered complete, and a functional, automated system that produces monodisperse emulsions of a given size at rates useful for industrial applications is in place. This equates to a strong TRL 5-6 system: a proven, integrated prototype, which can be customized, scaled, and productized with other industry participants instead of a lab experiment.

What can a business or laboratory do as part of a new project to utilize or expand AutoDropProd?

There are several pathways:

- Close cooperation with MIC to modify a droplet generator and control logic towards a given formulation.

- Intel’s incorporation of AutoDropProd-like modules within a Horizon Europe consortium in which MIC designs the chips, automation, and valorisation strategy.

- Codevelopment of a prototype production line, and inline quality control and standard operating procedures.

Since MIC has been a consistent microfluidic industrial partner on projects in the EU, it can also assist with proposal writing, work-package design, and exploitation plans, which is likely to boost the evaluation score for implementation and impact.

Why is it a strategic move to have an SME such as MIC participate in a European consortium on emulsions or microencapsulation?

Investment agencies seek a believable scaled passage between an idea and a product. MIC contributes:

- Practical experience in microfluidic droplet production of high throughput,

- A record of prototype delivery and transfer of technology, and

- Good advocacy on proposal writing and the management of the project.

As various calls demonstrate, the probability of success increased significantly when using consortia with MIC rather than averaged Horizon figures, and the main reason is that evaluators believe the engineering and valorisation components of the project will actually be delivered.