3D-printing of microfluidic MEMS for Lab-on-a-chip applications: M3D-Loc

Author

Christa Ivanova, PhD

Publication Date

February 14, 2018

Status

Keywords

additive manufacturing

Lab-on-a-chip

inkjet printing

microfluidic MEMS

multi-material 3D printing

microchannel fabrication

rapid prototyping

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

The detection of a disease at an early stage increases the chance of recovery. 3D-printed lab-on-a-chip is a promising device for early diagnosis of pathologies.

3D-printing lab-on-a-chip: introduction

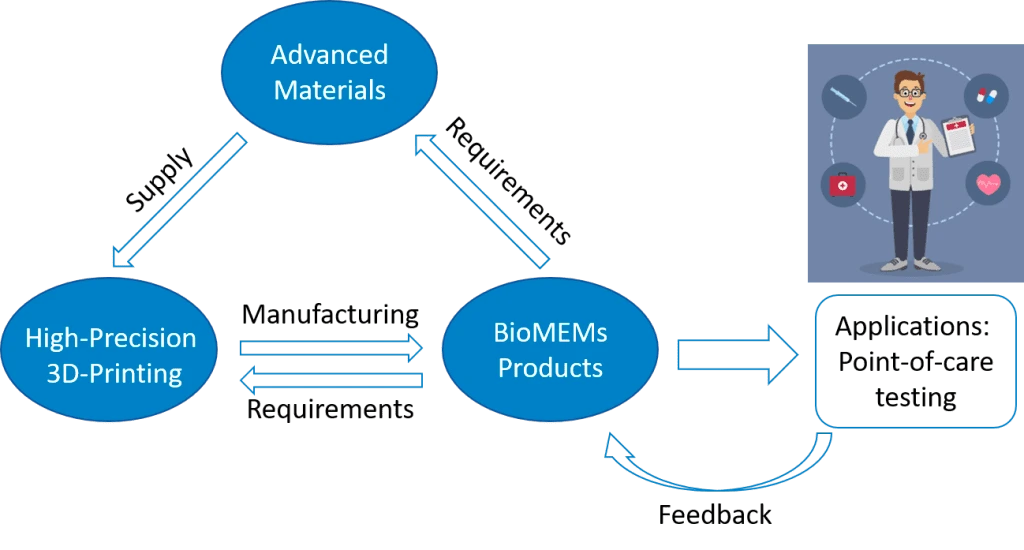

Microfluidic lab-on-a-chip technology, which allows the reduction of volume samples and analysis time and improves sensitivity, is a promising technology for developing efficient and portable diagnostic devices. However, the upscaling of lab-on-a-chip technology remains challenging.

3D printing facilitates the production of microfluidics devices, offering an affordable and accessible alternative to producing large amounts of labs on-chip in a reproducible way.

The M3D-LoC consortium gathers 18 industrial and academic partners from 9 countries to develop the next-generation 3D-printed microfluidic devices for diagnosis.

A pilot line combining different manufacturing techniques to produce microfluidic chips with a good resolution and a low rugosity will be built, and the performance of this new manufacturing platform will be evaluated by designing novel 3D-printed lab-on-chip devices for the detection of three diseases: tuberculosis, HIV and lung cancer.

3D-printing lab-on-a-chip: our role

In this consortium, we bring our expertise in microfluidics and lab-on-a-chip to design a microfluidic platform allowing the extraction, purification, and detection of DNA from human plasma in collaboration with biologists.

We also optimize and automatize the flow inside the 3D-printed lab-on-a-chip, thanks to the used flow control systems (valves, pressure controllers, pumps…).

This project has received funding from the European Union’s Horizon 2020 under grant agreement No 760662 (M3D-Loc project).

Image credit: Vectors designed by Freepik and vectorgraphit

Check our Projects

FAQ – 3D-printing of microfluidic MEMS for Lab-on-a-chip applications: M3D-Loc

What is M3D-LoC attempting to modify in diagnostics?

It drives lab-on-a-chip beyond beautiful one-off prototyping and makes them scalable and reproducible systems capable of realistically supporting the process of early disease detection. The concept is to combine microfluidics (rapid analysis, small volumes of samples) and 3D-printing such that the manufacturing process no longer becomes the limiting factor to implementation.

Why is microfluidics 3D-printing really useful?

3D-printing reduces entry cost, reduces the amount of time in iteration, and assists in upscaling production of uniform geometries. Chips with good feature resolution and low surface roughness are manufactured by printing in M3D-LoC, which has been known to be a pain point in optical readouts and flow stability.

What was it that the consortium established?

Pilot manufacturing line to combine complementary steps of fabrication to create next-generation 3D-printed microfluidic devices. The benchmarking platform is based on real diagnostic use-cases as well as test patterns.

What were the demonstrators’ diseases?

Three big-bang goals: tuberculosis, HIV, and lung cancer. It is by employing different clinical settings that the manufacturing strategy will be confirmed to be generic instead of being disease specific.

What was the contribution made by MIC (the Microfluidics Innovation Center)?

MIC designed and automated microfluidic platforms in close coordination with biologists to develop end-to-end DNA workflows that include extraction, purification, and detection of DNA in human plasma. We also adjusted the flow by valves, pressure controllers, and pumps to 3D-printed chips, and hence, exposure histories and timings can be reproduced across runs.

So what was the purpose of making so many references to low rugosity, does it make any difference?

Yes. Less roughness minimizes non-specific adsorption and optical scatter, respectively, to enhance the limit-of-detection and image quality. In high-gain assays that require surface finish, it is not cosmetic: should the assay (e.g., nucleic-acid tests based on fluorescence) require it, it is signal-to-noise. The manufacturing spec clearly identifies that M3D-LoC has good resolution and low roughness.

Is it possible to co-exist with traditional microfabrication with this printing method?

That’s the intent. The pilot line does not substitute all the techniques, it integrates them. The complex 3D structures (ports, manifolds, vertical interconnects) can be printed and membranes, electrodes, or optics of conventional MEMS/microfabrication can subsequently be added where necessary. The outcome is practical instrumentation as opposed to an individual dogma.

What is the first cooperation with MIC?

We begin by reworking the assay path (sample → lysis → purification → detection), and lock the chip and flow-control stack. We provide a protocol for working with valve/pressure profiles so your team can use it consistently. A prototype validated through calibration, SOPs, and an analysis template, something that can be used by partners who do not have microfluidics experts available, would be a typical deliverable. MIC usually focuses on microfluidic engineering, tool valorization, and proposal optimization for Horizon Europe bids. We have found that when a specialized SME such as MIC is included, proposal success increases by approximately 2 times that of official baselines on similar calls.

What is the relevance of this project to the general trends in point-of-care diagnostics?

It directly bridges the chasm between lab-quality microfluidics and production on a field basis. The validation of TB, HIV, and lung cancer demonstrates that the printed devices can be useful in early-stage detection cases where cost, reproducibility, and throughput are decisive, not just chip performance using a benchtop.