EIC Pathfinder Challenge 4

Waste valorization for circular production of fuels, chemicals, and materials

EIC Work Programme reference

HORIZON-EIC-2024-PATHFINDERCHALLENGES-01-04

Call deadline

October 29, 2025

Publication Date

May 02, 2025

Keywords

Circular economy

Waste valorization

Waste-to-value

Feedstocks

renewable energy

plastic recycling

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

Introduction to EIC Pathfinder Challenges

The EIC Pathfinder supports early-stage, high-risk research in science, technology, and deep-tech, aiming to lay the foundation for innovations that can reshape existing markets or create entirely new ones.

- Pathfinder Open: For breakthrough ideas across any scientific or technological field.

- Pathfinder Challenges: Focused on specific themes, funding coordinated portfolios of projects targeting strategic goals.

2025 funding at a glance

- Total budget: €120 million (4 Challenges, ~€30 million each)

- Project funding: Up to €4 million

- Projects per Challenge: 7–10

- 2024 success rate: 7.7% (31 of 401 proposals funded)

What is the Challenge on waste valorization about?

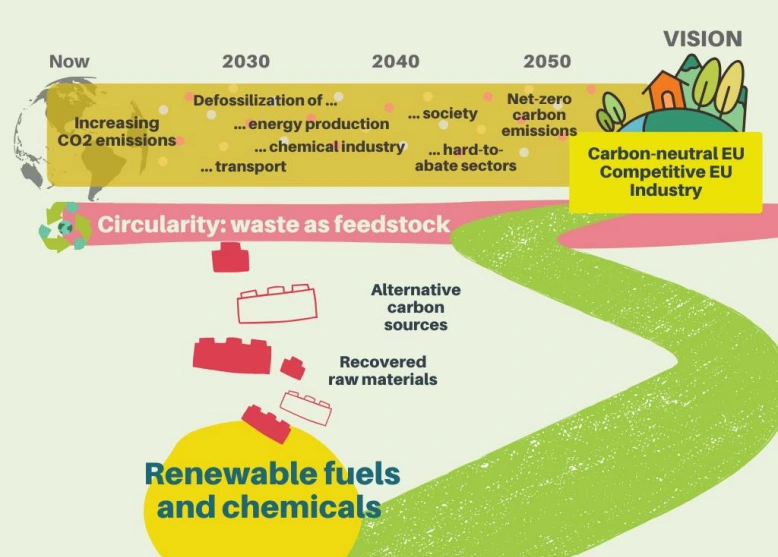

This Challenge aims to support the development of next-generation technologies that transform difficult-to-recycle waste streams into essential materials for a future circular economy. As fossil fuels remain the primary source of carbon feedstocks for fuels, chemicals, and materials, this Challenge seeks to “de-fossilize” production by using renewable energy and alternative carbon sources derived from waste.

This Challenge targets synthetic polymer materials (mixed and composite plastics, micro-/nanoplastics, untreated plastic waste, diapers, rubber, etc.), flue gases, wastewater, and streams where recycling is hard due to impurities, toxic additives, or material complexity. Solutions must be scalable, economically viable, and capable of generating high-value outputs while fostering collaboration within a portfolio of aligned projects.

More information on the EIC Pathfinder Challenge 4 can be found on the official page of the European Commission.

How can the MIC help with your project?

- Sorting micro-/nanoplastics, removing trace metals, or separating noxious additives from complex waste mixtures

- Screening microbial strains, enzymes, or synthetic biology constructs

- Parallelized experimentation

The MIC as the perfect SME partner

SMEs play a vital role in Horizon Europe projects by translating advanced scientific research into practical, scalable technologies. With deep expertise in microfluidics, we provide cutting-edge solutions to support the transition of complex waste streams into valuable feedstocks.

Our microfluidic systems accurately separate polymers, trace metals, and harmful additives from mixed waste. Furthermore, our platforms enable rapid, parallel screening of microbial strains, enzymes, and synthetic biology constructs, significantly accelerating the identification of effective biological agents for waste breakdown and resource recovery. These technologies are essential for developing efficient, scalable, and environmentally sustainable processes in line with the objectives of the EIC Pathfinder Challenge on circular waste valorization.

Objectives of the call

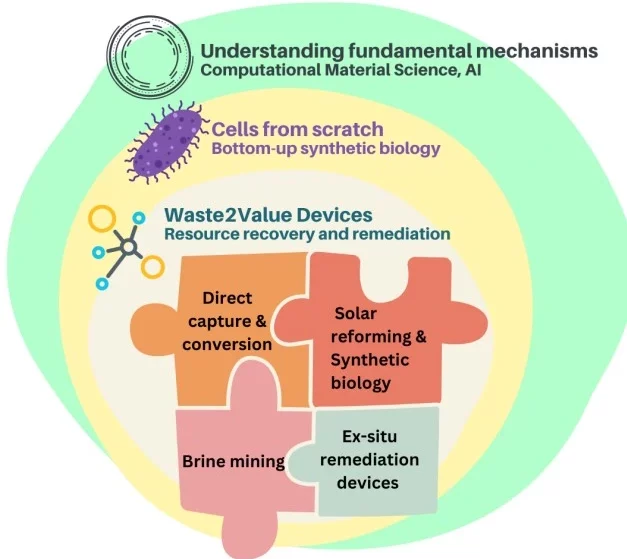

The funded project portfolio will collectively address three core areas. Only one proposal from each of Areas 2 and 3 will be selected, while Area 1 aims to fund projects covering a broad range of device categories.

Area 1: Fully integrated waste-to-value devices

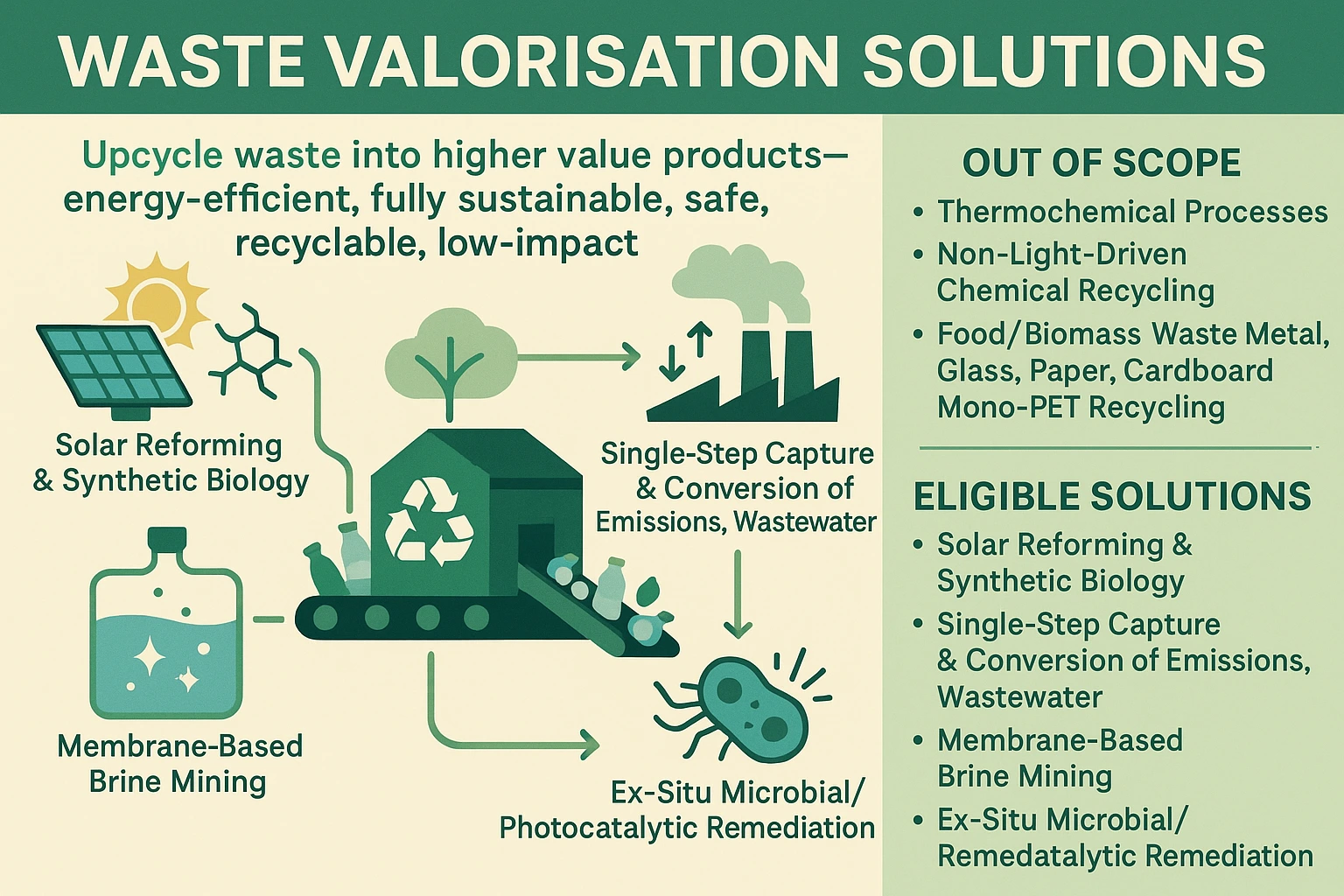

This area focuses on developing fully integrated, waste-to-value devices that convert complex waste streams into high-value products, beyond hydrogen as the sole end product.

Proposed technologies must upcycle waste into products of higher economic and environmental value, while being energy- and material-efficient, fully sustainable, and designed for safe, recyclable operation with minimal environmental impact. Solutions should address the entire waste valorization chain, function independently of large infrastructures, handle minimally sorted waste, and clearly benchmark their performance against current and emerging recycling methods. In addition, they must reach TRL 4 within 3–4 years.

Area 2: Understanding underlying mechanisms by means of computational material science and AI

- Investigate key physical, chemical, and biological phenomena relevant to various waste valorization devices, including catalyst development, interface engineering, and medium effects.

- Develop efficient, accurate, and less resource-intensive quantum mechanical and AI-based methods to support and interpret experimental work.

- Apply multiscale modeling to connect atomic, mesoscopic, and macroscopic levels and capture behaviors across different timescales.

- Take a holistic approach to mechanisms shared across device types, using devices from Area 1 to validate theoretical models.

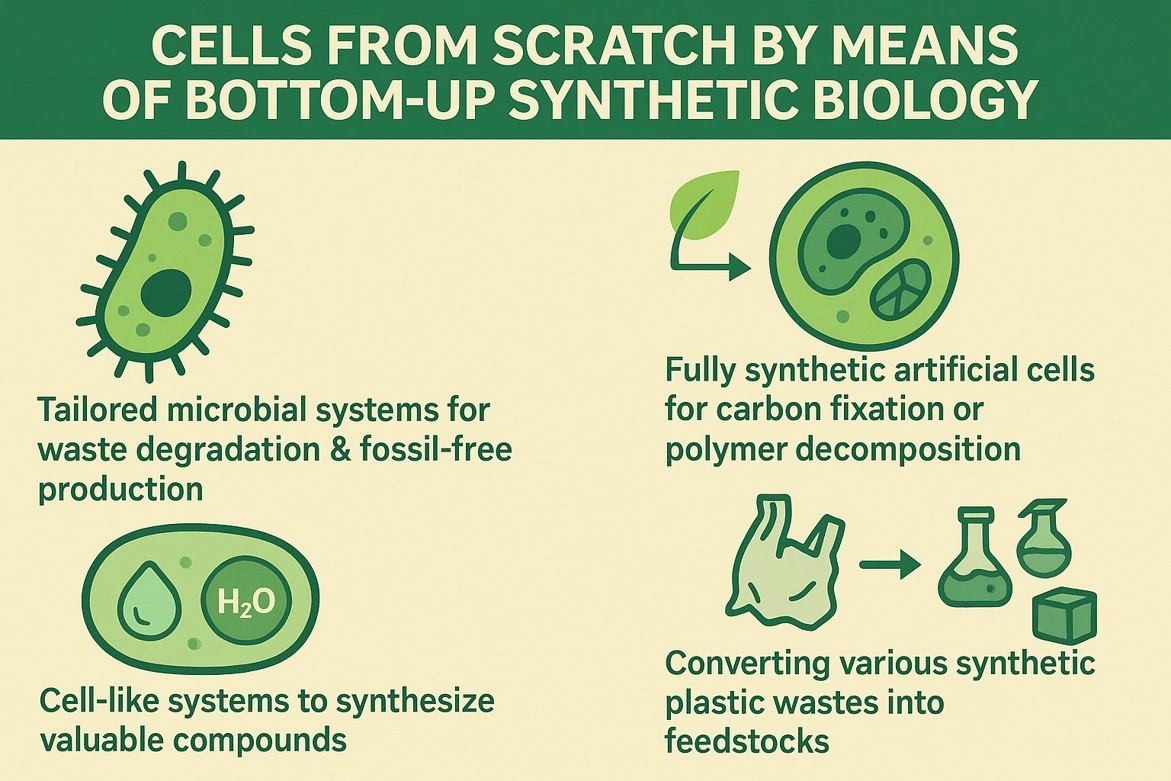

Area 3: Cells from scratch by means of bottom-up synthetic biology

Projects should address all the following specific objectives:

- Achieve breakthroughs in bottom-up synthetic biology to create tailored microbial systems.

- Develop artificial cells with carbon fixation for large-scale biotechnological use.

- Engineer systems to synthesize valuable compounds from basic building blocks like water and carbon oxides.

- Design systems capable of converting wastes to produce fuels, chemicals, and materials, with integrated but not necessarily autonomous modules.

Each proposal should address exactly one (and only one) of the three areas (first category), and be mapped according to values in the area (second category). Additional second categories include: waste feedstock, envisioned products, targeted sectors, future application scenarios, energy inputs, and desired functionalities.

What are the expected outcomes and impacts?

This Challenge aligns with key EU strategies, including REPowerEU, Fit for 55, the Renewable Energy Directive, the Waste Framework Directive, the Critical Raw Materials Act, and the Circular Economy Action Plan.

In the long term, this initiative will support localized and sustainable resource supply chains, especially for remote areas, by enabling access to advanced recycling technologies and reducing dependency on imported raw materials. Integrating waste valorization aims to increase the proportion of recycled waste, reduce environmental harm from landfilling and incineration, and support micro-/nanoplastic removal. Furthermore, it promotes decentralized, circular production of fuels, chemicals, and materials, transforming waste into a valuable local resource while significantly reducing fossil fuel reliance and associated emissions.

Deadlines of European Programmes

Download the MIC Horizon Europe 2026/2027 Calls Calendar:

-All Horizon Europe deadlines (by cluster and call).

The MIC already brings its expertise in microfluidics to the EIC Program:

FAQ - EIC Pathfinder Challenge 4: Waste-to-value devices

What is the real purpose behind this Challenge?

It is a risky, high-reward call under EIC Pathfinder that aims to convert heterogeneous waste streams into valuable products or energy in a step-change manner. Consider radically new conversion paths (electrochemical, photonic, bio-hybrid, microreactor-based), new separation and purification logics, or AI-controlled process control – not small improvements. It is premature science that can potentially shift from TRL 1-2 to TRL 3-4, with a clear roadmap to subsequent Tech Transition.

Who is eligible to apply?

Applicants (both small consortia and single entities) should be set up in an EU Member State or an Associated Country. In practice, the majority of winning teams are small, cross-functional teams of 3-5 beneficiaries (universities, RTOs, SMEs) whose approaches and facilities complement one another. Massive consortia are generally underperformers unless they are governed with a razor.

To what extent and how frequently?

Grants shall be financed up to 100 percent of the applicable direct costs and 25 percent of the applicable indirect costs (flat rate). The project sizes are typically 3-4 million EUR, with increased reactor yield and selectivity stable at 500 h, and a pilotable cartridge design. 36-48 months. Budgeting, which balances expenses against real risk-reduction achievements (e.g., increased reactor yield, stable selectivity at 500 h, pilotable cartridge design), sounds good to evaluators.

Which type of TRL development can be predicted?

Starting at TRL 1-2 (fundamental concepts, laboratory curiosities) and producing high-quality TRL 3-4 results: validated lab prototypes, reproducible data sets, and realistic scale-up speculations. When you are already at TRL 5, you are likely using the wrong instrument; when you are just theory without a validation plan, it is also a mismatch.

Which types of streams and outputs of waste are within the scope?

Mixed plastics, textile recycled materials, agri-food by-products, construction and demolition fines, municipal solid waste fractions, mining tailings, electronic waste, CO2-contaminated off-gases – assume your treatment method can contend with composition variability and impurity loads. The products can be monomers, platform molecules, critical minerals, advanced materials, or energy storage media. The quality specifications sought by evaluators include clean quality monomers (e.g., purity of monumental >99.5, ash or metal recovery >95) and persuasive analytics.

Which kind of evaluation criteria are reviewers using?

Three pillars:

-Excellence: audacious, state-of-the-art assertions with hard comparisons; plausible, falsifiable hypotheses; it is a well-founded methodology.

-Impact: a clear vision regarding what downstream exploitation and transition options will look like; measurable sustainability gains (e.g., E-factor, MJ/kg, CO2e/ton), and not a vague notion of a circular economy.

-Execution: lean work plan, strict risk management, a team that is a real cross-disciplinary (chemistry, materials, micro-/bioprocess, controls, LCA/TEA) one.

In the case of Challenges, suitability to the particular challenge roadmap is conclusive.

What technical KPIs would we be committed to?

Select a few of the ones that show real conversion and separation performance with realistic feed variability:

-Steady state yield and selectivity (e.g., 80% yield, >95% selectivity, 100 h stability).

-Specific energy requirement (MJ /kg product) and carbon intensity (kg CO2e /kg).

-E-factor (less than 1 depolymerization; less than 5 bio-routes) and solvent recovery (more than 95).

-Space-time-yield and throughput in intensified reactors (e.g., >2 g·L⁻¹·h⁻¹ bio-routes; >10 g·L⁻¹·h⁻¹ electrochemical).

-Contaminant tolerance (ppm-levels).

-Purity of the product according to standard (ASTM/ ISO grade, where applicable).

Any common pitfalls to avoid?

Several:

-Asserts that it is green and has no quantitative baselines.

-Extrapolating before impurity toleration data.

-Missing powerful analytics (absence of purity cross-validation/structure).

-Losses of separation energy; it usually dominates OPEX.

-Thin risk management – high-risk projects should have disciplined mitigation and not bravado.

-Theory requires hardware; no engineering underpinning to consortia.

What is the IP in the case of Pathfinder projects?

This remains the property of the provider; new results (foreground) are the property of the beneficiaries under the Consortium Agreement. Among partners, exploitation and access rights are negotiated. Reasonable open-science publication practices, actual names of owners, routes, and timeframes in exploitation plans are expected.

In what role does MIC play in a winning consortium?

We discuss the middle ground: microfluidic architecture, bespoke systems, sensorized plates, and quick prototyping, which turn good ideas into good ones. We also co-write proposals (with impact and implementation sections), find labs and SMEs throughout Europe, and create working prototypes. In previous Horizon Europe partnerships, the proposal success rate for a proposal with a specific SME added, such as MIC, has doubled on average relative to official baseline data for similar calls. We participate as partners in R&D and microfabrication, or as work-package leaders in screening/scale-down engineering.

What time frame are we supposed to take?

4-6 months plan to shape the consortium into submission-ready, including 2 internal reviews and 1 external dry run. For projects, a 36-48-month timeframe with quarterly decision gates is realistic. Reciprocate deliverables to evaluation rationale: Beta reproducibility, mid-term prototype stability, late reproducibility, LCA/TEA, and exploitation.