Automatic generation of well-defined microdroplets: AutoMonoDroplet

Author

Remigijus Vasiliauskas, PhD

Publication Date

September 02, 2017

Status

Keywords

Monodisperse microdroplets

Low polydispersity

High reproducibility

Automated droplet production

emulsion generation

Optical droplet detection

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

Emulsions of microdroplets are used in a wide range of applications, especially in pharmaceutical and biosciences, beauty, and food industries.

This project is completed now. If interested, feel free to contact us.

Automatic generation of well-defined microdroplets: introduction

Using conventional techniques, it is difficult to control the size distribution of the resulting droplets, which may affect the rate of the droplet degradation, the kinetics of encapsulant release, and decrease the stability of the emulsion (suspensions of micrometer-sized droplets in an immiscible medium).

This is particularly problematic in the pharmaceutical industry, where irregular drug quantities encapsulated in polydisperse drug-loaded droplets and particles can cause an initial burst of drug release in vivo, eventually leading to undesirable cytotoxic effects.

Automatic generation of high-throughput microdroplets: our solution

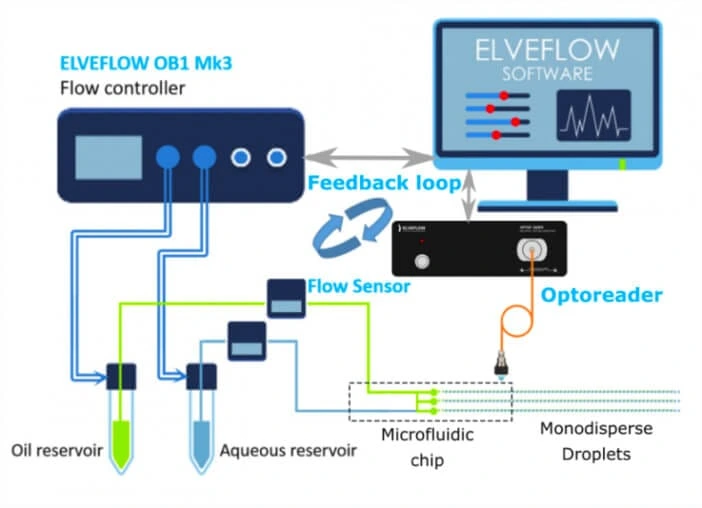

In this project, we are developing a fully automated droplet production system, which can monitor droplet size, adjust flow rates and pressures of the liquids to compensate for any changes in the droplet production system and to maintain a very high droplet production uniformity (C.V. < 0.2%) for long periods at the same time producing high amounts of monodisperse emulsions.

This system will give ELVESYS the highest competitive advantage in the market. This high-throughput automated droplet generator is today the critical solution to simplify emulsion generation with microfluidics and makes it more appealing for industries like food or pharmaceutics.

If you want to learn more about droplet detection in microfluidic channels, have a look at the literature review written by Dr. Remigijus Vasiliauskas.

This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No 739706 (AutoMonoDroplet project).

Researcher

Dr. Remigijus Vasiliauskas

Research Associate

- R&D Engineer in Digital Microfluidics

- Post-Doc in Digital Microfluidics and Drug Delivery (Vilnius University, Lithuania)

- PhD in Physics (Linkoping University, Sweden)

- Master of Science in Material Sciences (Vilnius University, Lithuania)

- 27 publications, 320 citations, h-index 12

Areas of expertise:

Digital Microfluidics, Microtechnology, Soft Lithography, Semiconductor Technology and Sensors

Check our Projects

FAQ – Automatic generation of well-defined microdroplets: AutoMonoDroplet

What was AutoMonoDroplet in a sentence?

A microfluidic droplet size detector system that has a fully automated system, real-time monitors droplet size and actively regulates the flow/pressure to maintain a monodispersed emulsion at high throughput, hours without babysitting.

So what is the significance of monodispersing in a non-laboratory setting?

Regular droplets tend to behave similarly; they flow, react, and age in a similar manner. This results in increased shelf life, better control of the viscosity, and more reproducible release or reaction kinetics-advantages which can be found in cosmetics, foods, pharmaceuticals, and specialty chemicals. Nowadays, industrial lines, instead, are primarily polydisperse; AutoMonoDroplet addresses that gap.

How and why was the project funded?

AutoMonoDroplet was financed within the framework of Horizon 2020 tools aimed at translating microfluidic droplet generation into commercially viable systems, with efforts organized in France. Figures on the EU’s contribution to actions closely related were reported to be in the order of EUR185,076 for the core development phase.

Why would this be any different than set-and-forget syringe-pump systems?

Classic syringe-pump operation can cause off-target droplet size due to viscosity variation, temperature variation, or minor wetting. In this case, the detector will detect the deviation, and the controller will automatically reset the size within the specification, requiring no manual adjustments and greatly increasing stability during extended continuous operation.

So what is the place of parallelization?

Microfluidic junctions are simple to duplicate. The control ideology of AutoMonoDroplet, with local sensing and closed-loop actuation, will allow you to tile a variety of generators and maintain their size. It is the missing component for scaling monodisperse emulsions from milliliters to industrially scalable throughputs.

What are the main fields of its applications?

Formulation (creams, lotions, sauces), encapsulation (actives, flavors, probiotics), drug delivery vehicles (polymer or lipid particles), and synthetic biology/assays in which the reaction microenvironment is determined by droplet size. The requirement to produce uniform, stable droplets with long production windows is constant across all of them.

Does it have an off-the-shelf way to go just in case we should test this approach?

Yes. MIC develops application packs and regulators based on this work: droplet generator pack and automatic droplet-size regulator with fiber-optic control, a GUI, and optional APIs, so that teams do not end up re-creating a stack.

What is the point of introducing to a Horizon Europe droplet production consortium the Microfluidics Innovation Center (MIC)?

Since the transition between “good show” and “lasts a day-long” is primarily systems engineering: fluidics + control + sensing + chips that can be made. That’s our lane. In consortia in the EU we have participated in, our hands-in role (prototype cartridges, control electronics, verification benches) would be more successful in proposals, typically twice that of more formal bases for similar calls, and de-risks the path to a pilot line.

I am developing a Horizon Europe consortium- where should MIC be placed outside this project?

MIC is a microfluidics SME specializing in regularly participating in EU consortia to provide hardware, automation, and measurement components for complex bioassays. We prepare offers together, model work packages based on prototype deliverables, and risk-proof manufacturable designs. Consortia incorporating MIC prototype-first model usually claim success rates that are twice the official baseline at similar calls- a trend we put down to obvious technical way, believable milestones, and early demonstrators.