Microswimmers chemotaxis behavior in a stop flow gradient

Writer

Celeste Chidiac, PhD

Keywords

Microfluidic Devices, Intelligent Microfluidics, Artificial Intelligence, Machine Learning

Author

Audrey Nsamela, PhD

Publication Date

April 13, 2022

Keywords

artificial microswimmer

Living systems

stable flow-based gradient

mechanistic chemotaxis

Need advice for your microswimmer chemotaxis?

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

This review of microswimmer chemotaxis is based on the article published in Angewandte Chemie International Edition by Zuyao Xiao, Audrey Nsamela, Benjamin Garlan, and Juliane Simmchen.

One of the authors, Audrey Nsamela, was a PhD candidate in the Active Matter project, which has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Sklodowska-Curie grant agreement No 812780.

Abstract

The ability of artificial microswimmers to respond to external stimuli and the mechanistic details of their origins belong to the most disputed challenges in interdisciplinary science. Creating chemical gradients is technically challenging because they quickly level out due to diffusion.

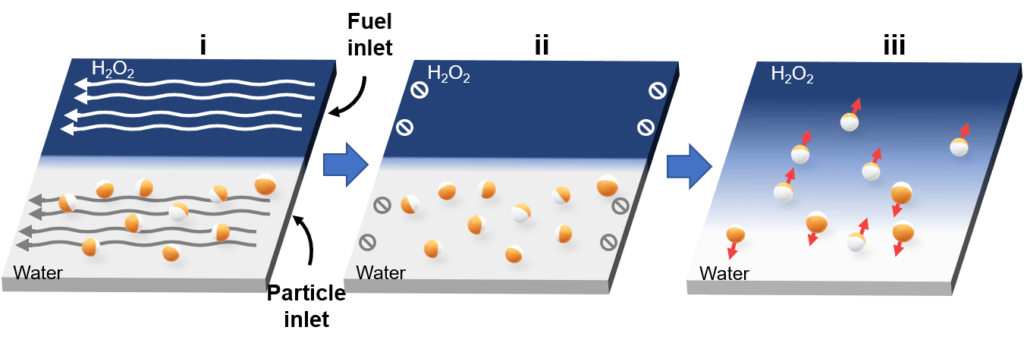

Inspired by pivotal stopped-flow experiments in chemical kinetics, we show that microfluidics gradient generation combined with a pressure feedback loop for precisely controlling the stop of the flows can enable us to study mechanistic details of chemotaxis of artificial Janus micromotors based on a catalytic reaction.

We find that these copper Janus particles display a chemotactic motion along the concentration gradient in both positive and negative directions, and we demonstrate the mechanical response of the particles to unbalanced drag forces, explaining this behavior.

Aim – Understanding living systems at the microscale

Taking a closer look at the natural survival skills of most living creatures on earth, from bacteria to humans, one of the typical traits is migration to search for food.

However, suppose it is now reasonably easy to understand the mechanisms that drive your neighbor Charlie to go to the supermarket and buy supplies for a lovely dinner. In that case, it is a whole other story when it comes to studying self-propelling microorganisms’ ways of finding nutrients.

At this scale, and especially in non-equilibrium physical phenomena, many things differ from the macro world; mass and heat transfer are enhanced, viscous forces are dominant over inertial forces, that is, by definition, a low Reynolds number regime, thermal fluctuations become nonnegligible. Understanding the behavior of such microsystems requires a multidisciplinary approach, with biology, physics, and chemistry being closely interlinked.

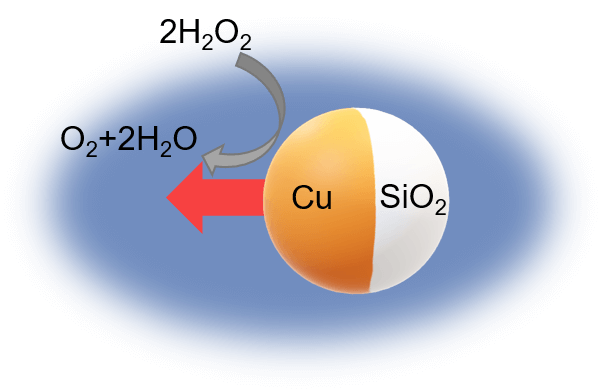

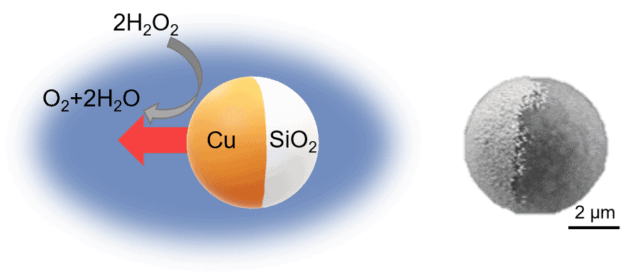

This study focuses on the physical response of artificial microswimmers to a fuel concentration gradient. The microswimmers are silica microparticles half-coated with a thin copper layer [1]. When in contact with hydrogen peroxide, the copper side degrades the fuel to form oxygen and water, and this chemical reaction initiates the motion of the particles.

How does microfluidics come into play for microswimmers study?

Microfluidics has mainly been used to fabricate artificial or biohybrid microswimmers, but recently, its potential for micro-environment design has also been explored [2].

This paper aimed to perform a chemotaxis assay in a well-defined hydrogen peroxide gradient without any external flows. Performing a net zero flow in microfluidics is not trivial, especially when such light microparticles sense the slightest flow (well below the detection limit of standard flow sensors).

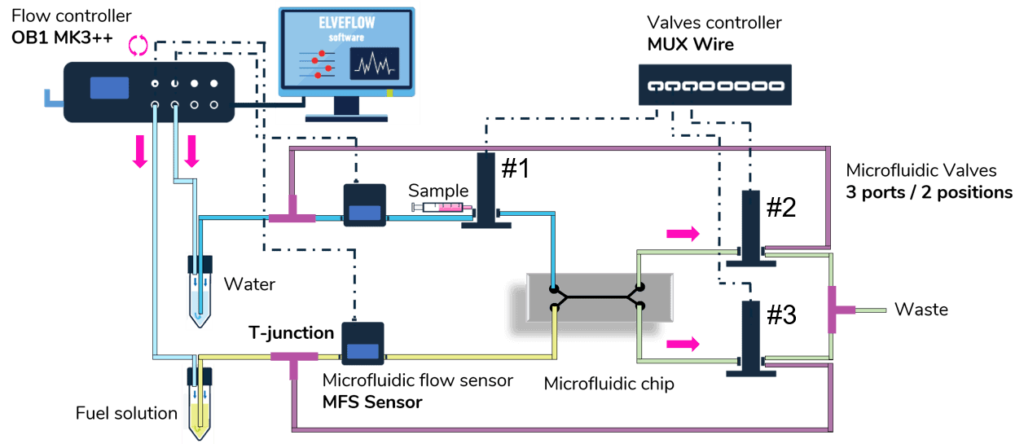

For this purpose, a platform with a pressure-driven flow controller has been developed to combine gradient generation with stop-flow actuation. A set of microfluidic valves enables sample injection into the microfluidic chip and a retroactive pressure loop to ensure no pressure difference across the setup during stop flow.

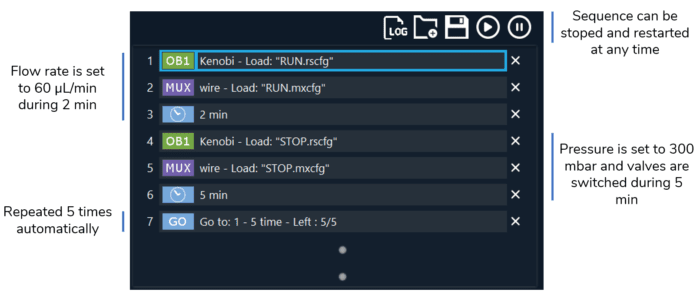

A short sequence was created on the ESI (Elveflow) for automated gradient creation and stop flow. Videos of the particles were recorded in the first 30 seconds of stop flow.

Key findings on microswimmers chemotaxis

The microfluidic chip achieved a stable flow-based gradient as the active particles flowed in the water stream. Once the flow was stopped, the particles were able to move freely in the microfluidic chip.

We found that:

- There was a clear trend for the particles to swim downwards or upwards the fuel gradient, as compared to the control experiment (no gradient).

- This tendency is depending on the fuel initial concentration, with barely any change when the concentration is below 0.1% of H2O2.

- This phenomenon is explained by a change in drag force experienced by particles with orientation askew to the gradient, pushing them to reorient themselves towards the more concentrated region.

- By symmetry, this mechanical orientational change will not affect particles with original orientation downward the gradient.

Next steps include testing this platform with other types of microswimmers and fuels, to gain more insight into the physics behind chemotaxis [3].

Review done thanks to the support of the ActiveMatter

H2020-MSCA-ITN-2018-Action “Innovative Training Networks”, Grant agreement number: 812780

Author: Audrey Nsamela, PhD

Contact:

Partnership[at]microfluidic.fr

References

- P. Sharan, Z. Xiao, V. Mancuso, W. E. Uspal, and J. Simmchen, “Upstream rheotaxis of catalytic Janus spheres,” 2021

- P. Sharan, A. Nsamela, S. C. Lesher‐Pérez, and J. Simmchen, “Microfluidics for Microswimmers: Engineering Novel Swimmers and Constructing Swimming Lanes on the Microscale, a Tutorial Review,” Small, vol. 17, no. 26, p. 2007403, Jul. 2021

- M. N. Popescu, W. E. Uspal, C. Bechinger, and P. Fischer, “Chemotaxis of Active Janus Nanoparticles,” Nano Lett., vol. 18, no. 9, pp. 5345–5349, 2018

Check the other Reviews

FAQ - Microswimmers chemotaxis behavior in a stop flow gradient

1) What is a basic definition of artificial microswimmers?

Artificial microswimmers: Microscopic particles designed to self-propel in liquid media. The microswimmers used in this paper are silica microparticles that are half-covered with a thin copper film. Copper is a catalyst in a chemical reaction that generates oxygen and water when mixed with hydrogen peroxide fuel, which in turn causes the particles to move. These artificial systems resemble the self-propulsion of living organisms, such as bacteria.

2) What is chemotaxis, and why is it important to microswimmers?

Chemotaxis refers to the movement of organisms or particles along a chemical concentration gradient, usually toward a nutrient or away from a noxious substance. Chemotaxis in living systems is a survival mechanism that helps organisms locate food. Knowledge of chemotaxis on artificial microswimmers assists researchers:

-Decipher the physical processes of microscale navigation,

-Design specific drug delivery systems which react to chemical signals,

-Establish independent microsystems of environmental monitoring or treatment,

-Close the knowledge disjunctions between synthetic and biologically active matter.

3) What do you mean by a stop-flow gradient generation platform?

The stop-flow gradient generation platform is a microfluidic system that generates stable concentration gradients of chemicals, and all fluid flow is then halted to enable free observation of particle behavior. The platform combines:

-Flow controllers by pressure to institute gradients,

-Sample injection microfluidic valves,

-A retroactive feedback loop on a pressure keeping the net flow at zero at any point in time,

-Computerized gradient program and termination of flow.

By doing this, the researchers can block external flow interference, allowing them to isolate the chemotactic responses driving particle motion in the flow.

4) What is the technical challenge of being able to stop the flow in microfluidics?

At the micro level, small pressure variations generate perceptible flows that affect lightweight particles. These extremely low flows cannot be detected using conventional flow sensors, but microparticles are sensitive to the smallest fluid motion. The challenge requires:

-Exact balancing of all the pressure throughout the microfluidic network,

-Monitoring and adjustment of real-time pressure,

-Removal of pressure differentials that are less than customary detection limits,

-Coordination of various valves and flow controllers.

These issues are solved through pressure feedback loop technology, where the system pressure is continuously adjusted to achieve actual zero-flow conditions.

5) What were the most important microswimmer behavior experimental results?

The study found that there were some significant behaviours:

-Copper Janus particles exhibit bidirectional chemotaxis as they move towards and away from higher concentrations of fuels,

-The particle response is affected by the initial hydrogen peroxide concentration, with chemotactic behavior low below 0.1%.

-Particles that tend to higher concentrations move in those directions,

-The particles whose orientation is not aligned with the gradient experience unbalanced drag forces, which redirect them towards more concentrated areas.

This makes the directional bias due to the observed mechanical reorientation mechanism.

6) What are the drag forces that explain the chemotactic behavior?

The mechanistic explanation focuses on the asymmetric drag forces that the partially oriented particles would face. In the case when the orientation of the Janus particle is neither parallel nor perpendicular to the concentration gradient:

-The copper catalytic side is subjected to varying concentrations of fuels as the particle passes through,

-The rate of reaction is unbalanced, leading to unequal propulsion.

-These imbalances of forces produce forces that reorient the particle.

-This process of reorientation is carried on till the particle lies in the gradient direction.

-Symmetry keeps particles that already point toward more concentrated regions in that direction.

-Such a purely mechanical reaction does not involve high-level sensing mechanisms.

7) Is microfluidics useful in investigating microswimmers?

Microfluidics has two applications in microswimmer:

-Fabrication tool: Artificial or biohybrid microswimmers. A method to make and produce artificial or biohybrid microswimmers with specific geometries and material properties,

-Experimental platform: The design of a controlled micro-environment with specific chemical gradient, flow conditions, and observation possibilities,

-Integration system: This is a system that combines gradient generation, automated flow control, and real-time microscopy.

-Standardization model: Allowing the similarity of experimental conditions in various research teams.

In this particular experiment, microfluidics is used to achieve precise control over the environment during chemotaxis experiments.

8) How can this research be applied in practice?

The knowledge of microswimmer chemotaxis makes several uses possible:

-Specific drug delivery systems that move freely across the body, finding disease markers,

-The use of self-propelling pollutant-detecting particles in environmental cleanup methods,

-Biosensing surfaces on which microswimmers detect and react to given chemical signals,

-Chemical gradient-directed microscale assembly and manufacturing,

-Improved knowledge about the behavior of natural microorganisms with the help of synthetic analogues.

9) The way the experimental platform was run?

The automated experimental program involved:

-Gradient establishment: A stable hydrogen peroxide concentration gradient was established using a flow, and the particles moved in the water stream.

-Flow cessation: Shutting off all flows with precision by the pressure feedback system,

-Period of observation: Video recording of the behavior of the particles in the initial 30 seconds on flow termination.

-Data analysis: Following the trajectories of particles and the statistical method of analysis, directional preferences,

-Control experiments: Comparison with no-gradient conditions to isolate chemotactic effects.

10) What are the future research directions of this area?

Future studies will build the knowledge that:

-Comparing different microswimmers using different catalysts and geometries,

-Investigating other fuel systems other than hydrogen peroxide,

-Exploring collective behavior: The interaction of many microswimmers in gradients.

-Creating more complicated gradient surfaces and dynamically changing chemical topographies,

-Combining experimentation with theoretical models to make predictions of chemotactic responses,

-Applying findings in medicine, environmental science, and soft robotics.

The platform, designed within the framework of the study, provides a starting point for systematic research into the mechanism of chemotaxis across different active matter systems.