Workshop - Microfluidics for bioremediation

Author

Eve-Line Bancel, PhD

Olivier Fournier, PhD

Léna Rasse

Océane Jan

Publication Date

September 04, 2025

Keywords

Microfluidic bioremediation

Microfabrication

Ecotoxicology

Your microfluidic SME partner for Horizon Europe

We take care of microfluidic engineering, work on valorization and optimize the proposal with you

This workshop was part of the Edaphos summer school, which took place on August 25-26, 2025, at Montbéliard, France.

Find the Edaphos project page here.

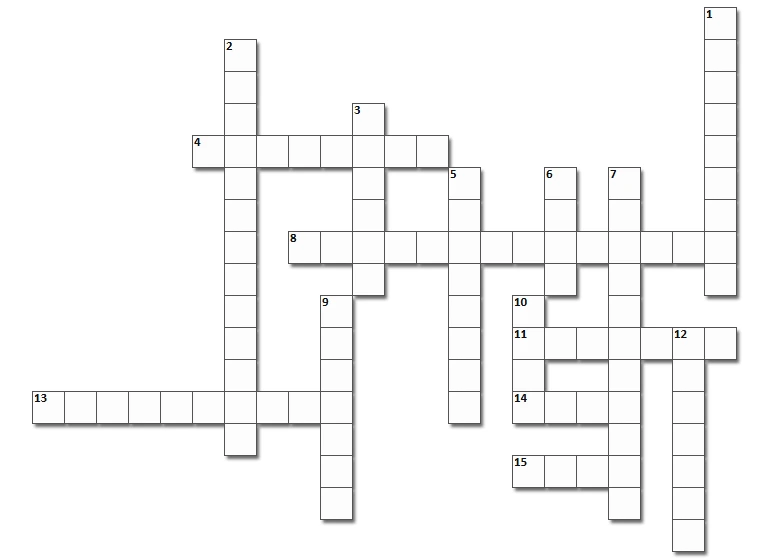

Let’s start with some fun with the microfluidic crossword below:

Microfluidic crossword:

- A harmful substance that contaminates the environment

- Technology that controls small volumes of fluids in microsystems

- Device that detects or measures a physical property and records, indicates, or otherwise responds to it

- Spatial variation of a substance concentration that can be generated in a microfluidic chip

- Micro-organism used in ecotoxicology as a model to assess the quality of the soil

- A microplatform that allows precise control, manipulation, and analysis of tiny volumes of fluids

- Small pump that can be modulated to parallelize experiments

- Use of living organisms to clean up pollution from soil, water, or air

- European project which aims to develop a novel framework for land rehabilitation and ecological restoration of degraded areas featuring nature-based solutions technologies

- Biocompatible and transparent silicon polymer often used to make microfluidic chips

- Micro-reactor generated by the encounter of 2 non-miscible phases

- Sciences that explore the relationship between organisms and their surroundings

- Technology that fits lab functions into a tiny microfluidic device

- The upper layer of the ground made of minerals and organic matter

- Thermoplastic polymer used to make a microchip

Introduction to microfluidics

Microfluidics refers to the science and technology of handling fluids in microscale environments. At this scale, fluids flow in a laminar regime, where viscous forces dominate over inertial forces, yielding well-defined streamlines and diffusion-dominated processes as opposed to convection-dominated processes. This technology can hence enable fine control of experimental conditions, including pressure, flow rate, temperature, gas environment, or pH, for example. It allows for miniaturization, parallelization, as well as automation and standardization of tests and assays.

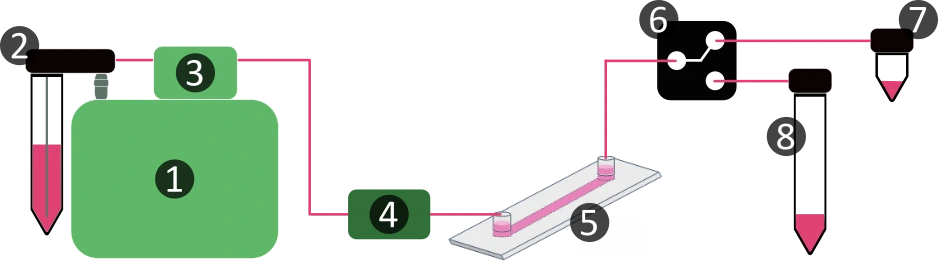

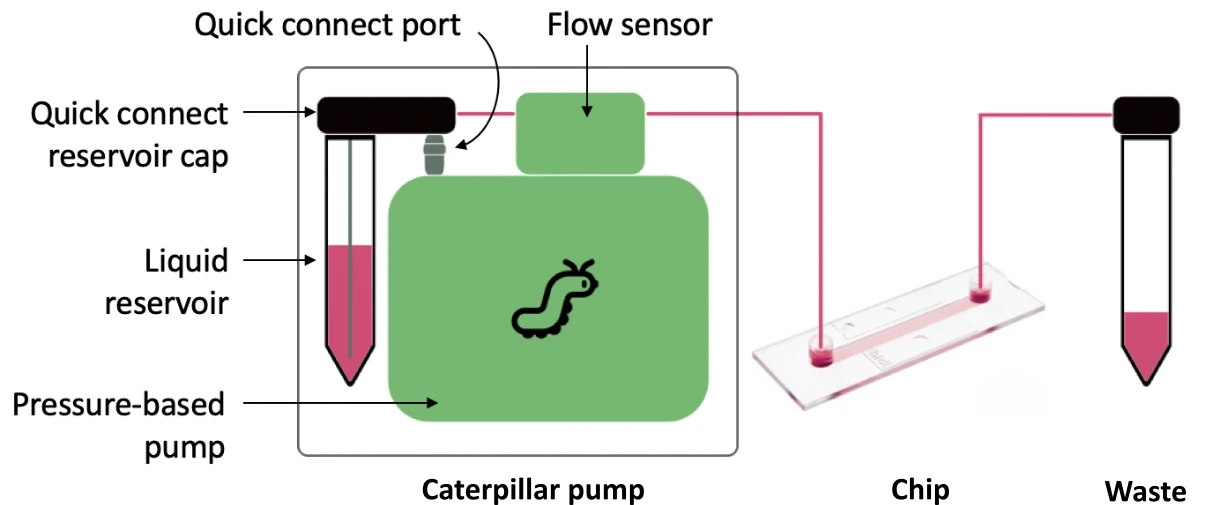

By way of example, a conventional setup consists of a pump system (pressure-driven pump, syringe pump, peristaltic pump) that feeds an on-chip system from a reservoir. Sensors can be added to track the quantities of interest. Valves can be used to connect and select among different functionalities of the circuit (injection of compound in the system, selection of different fluidic paths, timed collection of samples, etc). To sum up, a microfluidic system can be divided schematically between the chip containing the subject of interest (cells, organs, microorganisms, membranes, etc.) and all the surrounding instrumentation controlling the microenvironment of the system on the chip, as pictured in Figure 1.

Introduction to microfabrication

Microfabrication covers techniques to produce the microfluidic chips from various materials such as glass, thermoplastic polymers, or PDMS (polydimethylsiloxane – a silicone-based polymer). In a bioremediation context, creating custom microstructures is particularly valuable for reproducing complex environmental conditions, tailoring designs to specific research needs, and integrating them with potential analysis methods such as microscopy or spectroscopy. Typical challenges in microfabrication consist of the accurate control over the dimension and geometry of the chip for predictability and reproducibility, in the selection and chemical treatment of suitable materials, and in tight bonding between the different layers of constitutive materials to avoid leakage.

Basics of microfluidics - from the chip manufacturing to microfluidic system engineering

Topic 1: Microfabrication: Ways of producing microfluidic chips, and application to a microfluidic key chain

The first part of the morning session will cover the basics of microfabrication applied to microfluidics. During this workshop, the participants will be introduced to the concept of microfluidic chips, learn about the main techniques and materials used to fabricate them, and understand the specificities and challenges specific to each technology.

A short lecture will be given as a way of introduction on the key steps and requirements of microfluidic chip production, with a specific focus on the selection of the chip material. In particular, a comparison between PDMS and PMMA as chip material will exemplify the impact of the material on the production and on the use of the chip. The main portion of the session will consist in applying this knowledge in the production of a microfluidic key chain out of PMMA, following a protocol developed by the MIC to easily produce thermoplastic chips.

Topic 2: Microfluidic instrumentation: introducing the Caterpillar pump

A microfluidic system can be roughly divided into two essential parts: the chip and the fluidic system controlling the fluid. As part of the EDAPHOS microfluidic system, MIC is developing a pressure pump to drive the flow. The pump has the advantage of being compact and modular, allowing for the concatenation of various pump modules, much like segments of a caterpillar, to parallelize tests of exposure to metal pollutants. Other pump technologies exist to control the flow according to specific needs, as summarized in Table 1.

Table 1: Comparative summary of different types of pumps

Pump system | Flow profile | Flow rate | Flow rate control | Flow continuity |

Syringe pump | Oscillating, pulsatility depends on the pump | Suitable for low flow rates | Precise, controlled by the pump | Disrupted when pull/push transition or when syringe empties |

Peristaltic pump | Pulsatile, can be reduced with a dampener | Not suitable for low flow rates | Moderate, controlled by the pump and tubing selection | Continuous flow, can be disrupted when refilling reservoirs* |

Pressure pump | Highly stable profile; Variety of flows possible: pulsatile, steady, stepwise, custom | Suitable for both low and high flow rates | Very precise; Uses a flow sensor feedback loop | Continuous flow, can be disrupted when refilling reservoirs* |

*Infinite volume looping in a recirculation setup

The second part of the morning session will hence consist of learning the basics of working with a microfluidic system. During this workshop, the participants will work with a simplified system consisting of this Caterpillar pressure pump, a reservoir, a chip, and a waste. The focus will be on hands-on experimentation from assembling an air-tight, leak-free system to controlling the flow profile through the chip, schematized in Figure 2.

This introduction to microfluidic systems will provide a first grasp of the challenges associated with such systems, the physical principles at play (laminar flow, Hagen-Poiseuille equation, and the importance of diffusion), and the numerous possibilities for system tailoring, whether through chip architecture or microfluidic system assembly. Here, we use the example of two types of chips (gradient generator and droplet generator) to illustrate the importance of the microfluidic system surrounding the chip in controlling the parameters of the experiment.

Application of microfluidics to ecotoxicology

Topic 3: EDAPHOS development: C.elegans-on-a-chip for ecotoxicity characterization

Within the EDAPHOS project, task 2.4 aims at developing new tools for the ecological and ecotoxicological characterization. The work focuses on developing a toxicity test using Caenorhabditis elegans as a soil organism to characterize the potential effects of contaminated soils on the nematode groups. Nematodes are among the most abundant soil invertebrates (>106 individuals/m²), and they play key roles in decomposition, energy flows, nutrient cycling, and microbial regulation. Therefore, these organisms may be of significant interest when considering the hazard assessment of soil or complex matrices. Among them, C. elegans was proposed as a relevant species due to its well-known biology, ease of lab handling, and short life cycle (eggs to eggs in 120 h at 20 °C, Figure 3). Moreover, a protocol for ecotoxicity characterization is already standardized (ISO 10872).

In the EDAPHOS project, this model is used to develop an assay for assessing the toxicity of contaminated soil leachate in a microfluidics/microchip environment. A microfluidic prototype was constructed, and a specific protocol was established to assess the growth inhibition of C. elegans continuously exposed to soil leachates. Optimal conditions for the growth (food concentration, flow rate) were established.

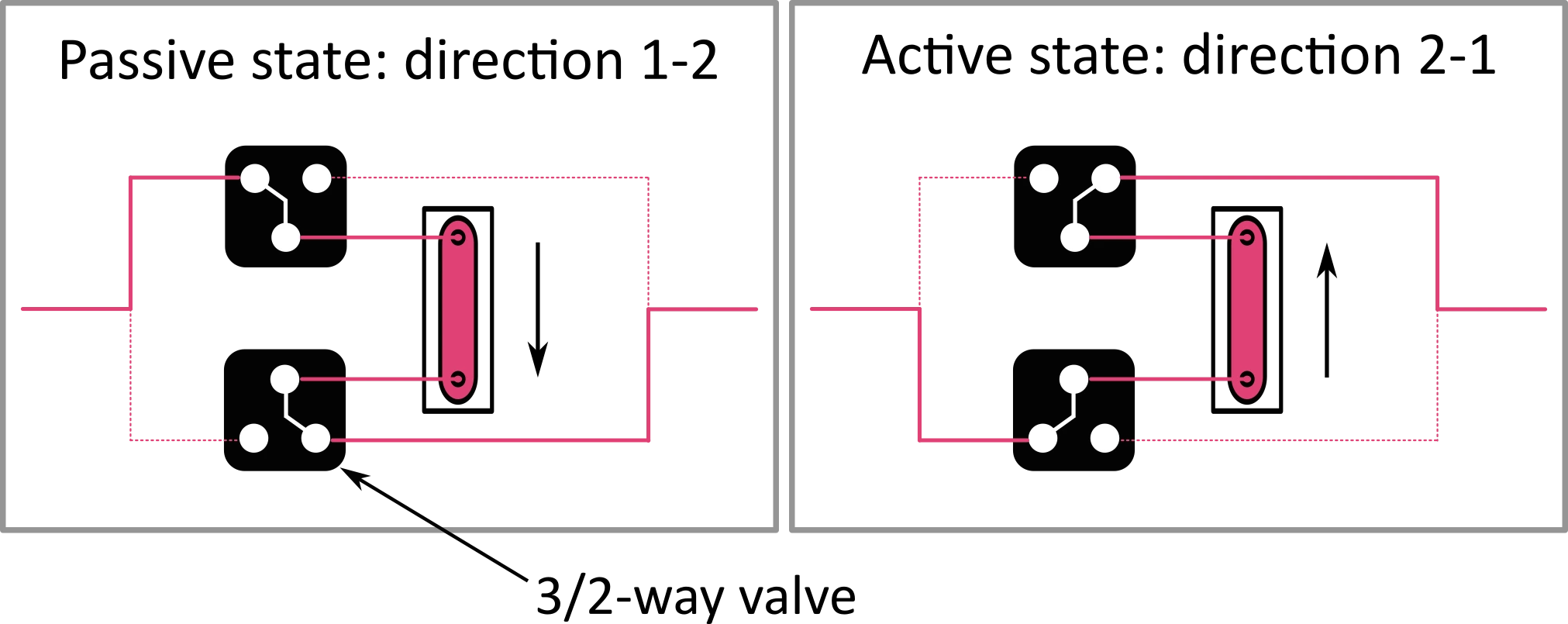

In this workshop, participants will practice handling biological samples in a microfluidic system and use a system of higher complexity that integrates valves for fluidic routing (Figure 4). More specifically, they will prepare microchips with nematodes and run the first steps of a typical growth cycle test.

To go further:

- Website (application notes, details on microfluidic innovations and instruments, typical microfluidic setups, update on research projects): https://microfluidics-innovation-center.com/

- Youtube: https://www.youtube.com/@MicrofluidicsInnovationCenter

- EDAPHOS webinar focused on “Microfluidics in soil ecotoxicology and microbiology”: https://youtu.be/q9JwPqNhtBA?feature=shared

Download the workshop PDF!

Acknowledgements

This workshop was prepared under the European Union under HORIZON-MISS-2022-SOIL-01, grant agreement No. 101112768 (EDAPHOS).

FAQ - Microfluidics for bioremediation

What is the reason of the logic of matching microfluidics and bioremediation?

Due to the fact that both bioremediation and soil ecotoxicology are abundant with sloppy variables: gradients, slow diffusion, heterogeneous samples, intermittent exposure and organisms that respond to minute environmental changes. Microfluidics excels at the reverse: planned microenvironments – constant or programmed circulation, stable gradients, repeatable exposure circumstances, and an opportunity to conduct tests in parallel rather than sequentially in a large-scale lab equipment.

What are the real microfluidics basics that the participants receive during the workshop?

You begin with fundamental physical intuition: laminar flow (not turbulence), the importance of viscosity, and the reason diffusion often becomes a large-scale mode of transport. Based on this, the workshop describes a typical experimental system as comprising of two parts coupled to each other:

-the chip (cells, microbes, organisms, membranes, or soil leachates are processed), and

-the instrumentation (pump, reservoirs, sensors, valves, sampling/waste).

The difference between chips and systems is important, most of the chip troubles are disguised system troubles.

What is microfabrication, and what is the reason why PDMS and PMMA continue to be mentioned?

The microfabrication block is concerned with the production of chip (and what that means to your experiments). One of the most important examples is the comparison between the PDMS and PMMA:

-PDMS has found extensive application in academic prototyping (transparent, flexible, simple to mold), and has its share of quirks (surface chemistry, absorption behavior, bonding constraints).

-The PMMA (a thermoplastic) is more oriented to repeatable thermoplastic processes and logic of scale.

The participants practice these concepts during a real-life task: the creation of a PMMA microfluidic key chain in a protocol that has been designed by the MIC to make the fabrication of thermoplastic chips chips more affordable.

What is the “Caterpillar” pump and what is so different about it?

The Caterpillar is a small, modular pressure pump which is being developed in the EDAPHOS microfluidic system environment. The design concept is easy but effective; you can add pump modules in a concatenating way in a segment manner in order to parallelize experiments- useful when the experimenter would prefer to have more than one pollutant exposure condition in parallel as opposed to sequential runs. This in practice is a highly practical solution to the practical limitation that researchers are faced with: a lack of time, a lack of venues, too many variables.

What is the comparison of syringe, peristaltic and pressure pumps in micro-fluidic ecotoxicology studies?

The two are not at all interchangeable and the compromises become apparent quickly as soon as you attempt to use long exposures or low flow rate:

-Syringe pumps are accurate at small flow rates, however, intermittency may occur during push/pull switches, or when the syringe fills.

-Peristaltic pumps are simple to deliver continuously, but they are usually pulsatile and perform poorly at very low flow rates (unless overly damped).

-Pressure pumps can provide a very steady flow and may produce tailored profiles (steady, pulsatile, step-like), usually with a flow sensor feedback loop to maintain tight control.

One little footnote, which makes a big splash in environmental testing: recirculation systems may pretend to be of infinite volume looping, and this can alter your intuitive concept of the limits of the reservoir and continuity.

What is involved in the instrumentation phase of participants, do they simply observe or are they involved in building?

They build and troubleshoot. The workshop focuses on getting a leak-free airtight microfluidic system (which, this is, half the battle) and experimenting with the behaviour of flow patterns using a chip. It is not just simple the learning of how to connect the tubing, but also the reasons behind the system specifications influencing the rate of diffusion, gradient formation, and exposure reproducibility.

Case study in ecotoxicology – why Caenorhabditis elegans?

The workshop in the context of EDAPHOS emphasizes the creation of the C. elegans-on-a-chip strategy of characterization of ecotoxicity. This is an expedient decision: C. elegans is modeled with great biological clarity, easy to manipulate, and with a short life cycle (especially the egg-to-egg interval of approximately 120 hours at 20°C). It also has an applicable standardized base in the field (the workshop makes reference to ISO 10872).

The greater ecological explanation is that nematodes are very numerous in soils (frequently discussed above 106 individuals per m2) and they are important in decomposition, nutrient cycling and microbial control-so they are not merely a laboratory interest.

What is the bidirectional flow module that is discussed in the workshop, and why would I care?

It is a routing idea that is fluidic and switches perfusion direction across a chip with a single source of pressure usually with 2 3/2-way valves that regulate the switching. The significance of this: bidirectional perfusion has the potential to control uniformity of exposure, decrease clogging or local depletion effects in certain designs, and allow more complex protocols without multiplying pumps.

Which would be the realistic position of MIC in a Horizon Europe proposal that is based on soil restoration?

MIC often provides assistance in areas where projects become technically unsound: microfluidic design, system engineering (chips + instrumentation), prototype development and getting it to work reliably with other partners. On the project side, MIC also does valorization and proposal optimization, which is helpful when you are interested in a project consortium that sounds implementable rather than aspirational.

A real-life observation that most coordinators privately admit: Horizon Europe success rates can be harsh (usually somewhere in the 10-20% range based on the call). Including an SME capable of constructing and eliminating hardware prototypes is more likely to build credibility. MIC also monitors this internally and usually observes a near two-fold increase in the success of proposals when a robust industrial microfluidics alliance is incorporated early (as no longer a last-minute “technology source).